Upset Thread Rebar Coupler

Description

Upset Thread Rebar Coupler is a connector used to join reinforcing bars, formed by swaging the ends of threaded bars to create straight threads. In rebar connections, the diameter of the section to be joined is first enlarged using rebar cold extrusion press machine. Threads are then machined onto this enlarged section. The rebar ends, featuring specially formed straight threads, interlock with the straight-threaded sleeve to form an integral unit. This mechanical interlocking force achieves the purpose of connecting the rebars.

The Anda upset thread rebar coupler connection technique, renowned for its high strength, exceptional reliability and ease of construction, finds extensive application in scenarios including: high-rise and super-tall buildings; stadiums and exhibition centres with large-span structures; long-span bridges in seismic zones and marine bridges; underground railways and tunnel projects; water conservancy and port engineering; segmental fabrication and connection of reinforcement cages;> and the connection of bent and fixed rebars

Technical Parameters of Upset Thread Rebar Coupler

| Rebar Dia (mm) | Outer Dia (mm) | Length (mm) | Thread |

| Φ16 | 26 | 40 | M20×2.5 |

| Φ18 | 29 | 44 | M22×2.5 |

| Φ20 | 32 | 48 | M24×3.0 |

| Φ22 | 35 | 52 | M27×3.0 |

| Φ25 | 40 | 60 | M30×3.5 |

| Φ28 | 44 | 66 | M32×3.5 |

| Φ32 | 50 | 72 | M36×4.0 |

| Φ36 | 56 | 80 | M39×4.0 |

| Φ40 | 62 | 90 | M45×4.0 |

Advantages of Upset Thread Rebar Coupler

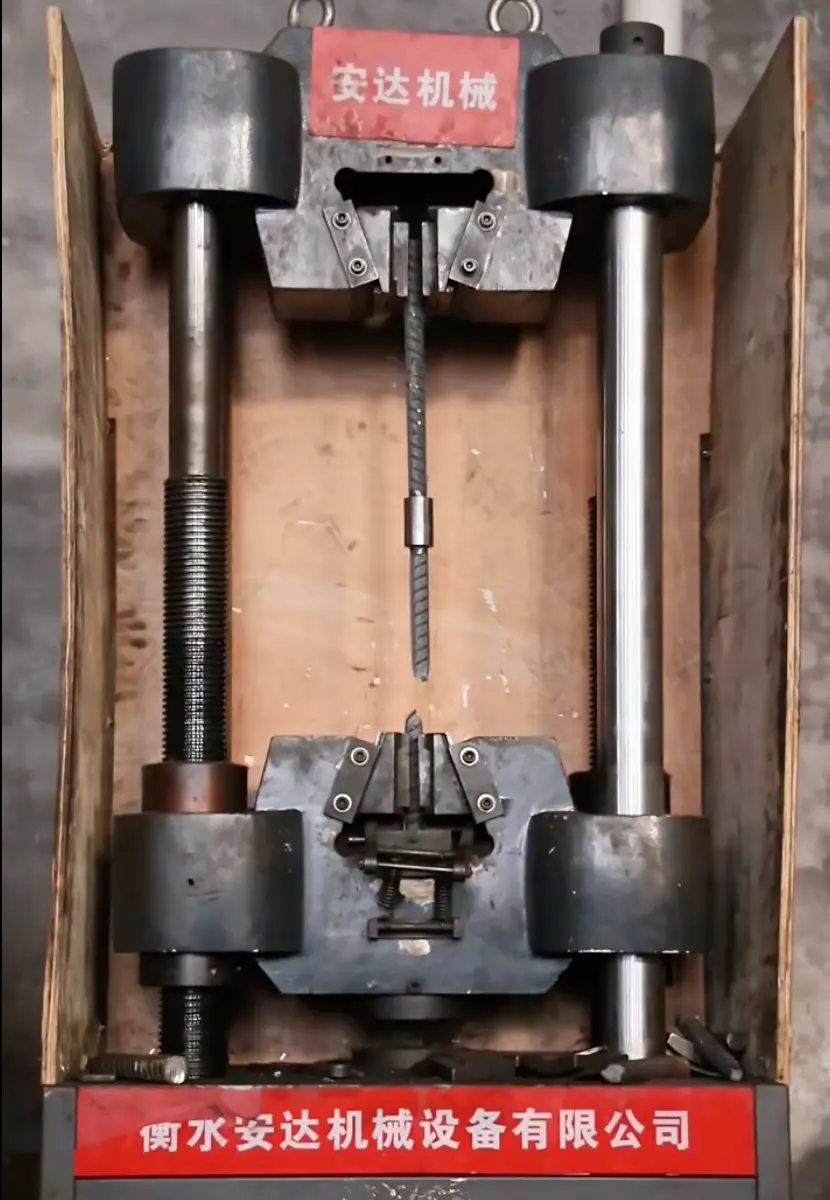

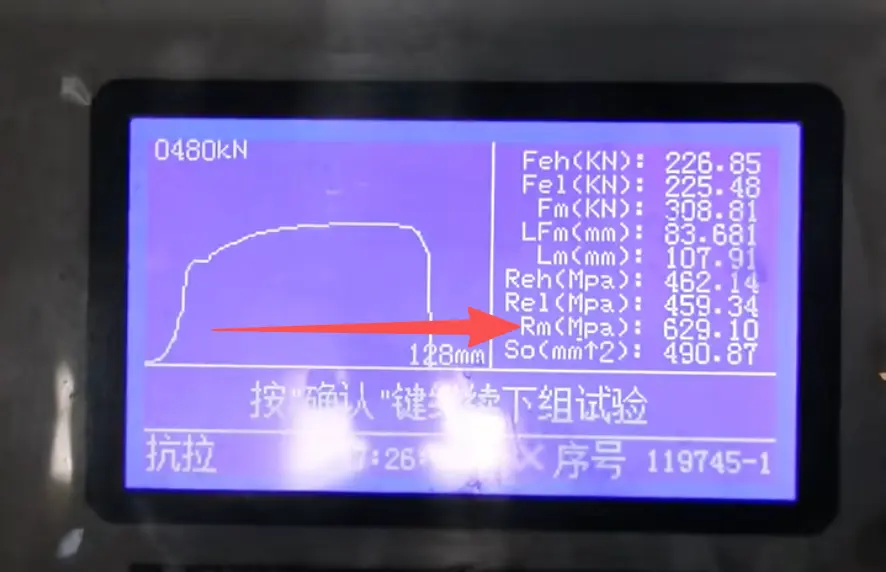

- High strength: Joint strength exceeds that of the parent steel reinforcement, meeting structural ultimate load-bearing requirements.

- Stable performance: Quality remains reliable, unaffected by factors such as tightening torque or ambient temperature.

Convenient installation: Requires no complex equipment, with straightforward operation suitable for dense reinforcement and confined spaces. - High work efficiency: Lower overall costs than welding or mechanical compression connections, coupled with rapid installation speed to shorten project timelines.

- Environmentally friendly and safe: Eliminates open-flame operations, mitigating fire hazards and complying with green construction requirements.

Product raw materials

The raw material for Anda Upset Thread Rebar Coupler is 45 # steel;

Chemical composition of 45# steel

| chemical elements | C (%) | Si (%) | Mn (%) | P (%) | S (%) |

| content range | 0.42–0.50 | 0.17–0.37 | 0.50–0.80 | ≤0.035 | ≤0.035 |

Mechanical properties of 45# steel

| Property | Yield Strength | Tensile Strength | Elongation | Reduction of Area | Hardness |

| Value | ≥345 MPa | ≥630 MPa | ≥17 % | ≥45 % | ≤197 HB |

Advantages of 45 steel

- High strength and hardness: Grade 45 steel contains an appropriate amount of carbon, endowing it with high strength and hardness, enabling it to withstand considerable heavy loads.

- Excellent wear resistance: Due to its relatively high carbon and manganese content, Grade 45 steel exhibits excellent wear resistance, making it suitable for manufacturing mechanical components requiring long-term service.

- Workability: Grade 45 steel is readily machinable and weldable, amenable to shaping through various processing methods for versatile application across different scenarios.

- Resistance to deformation: Following proper heat treatment, Grade 45 steel exhibits minimal susceptibility to deformation or cracking, demonstrating commendable dimensional stability.

- Moderate pricing: Grade 45 steel offers relatively accessible pricing, facilitating its widespread adoption in numerous sectors including construction, rebar sleeves, and machinery.

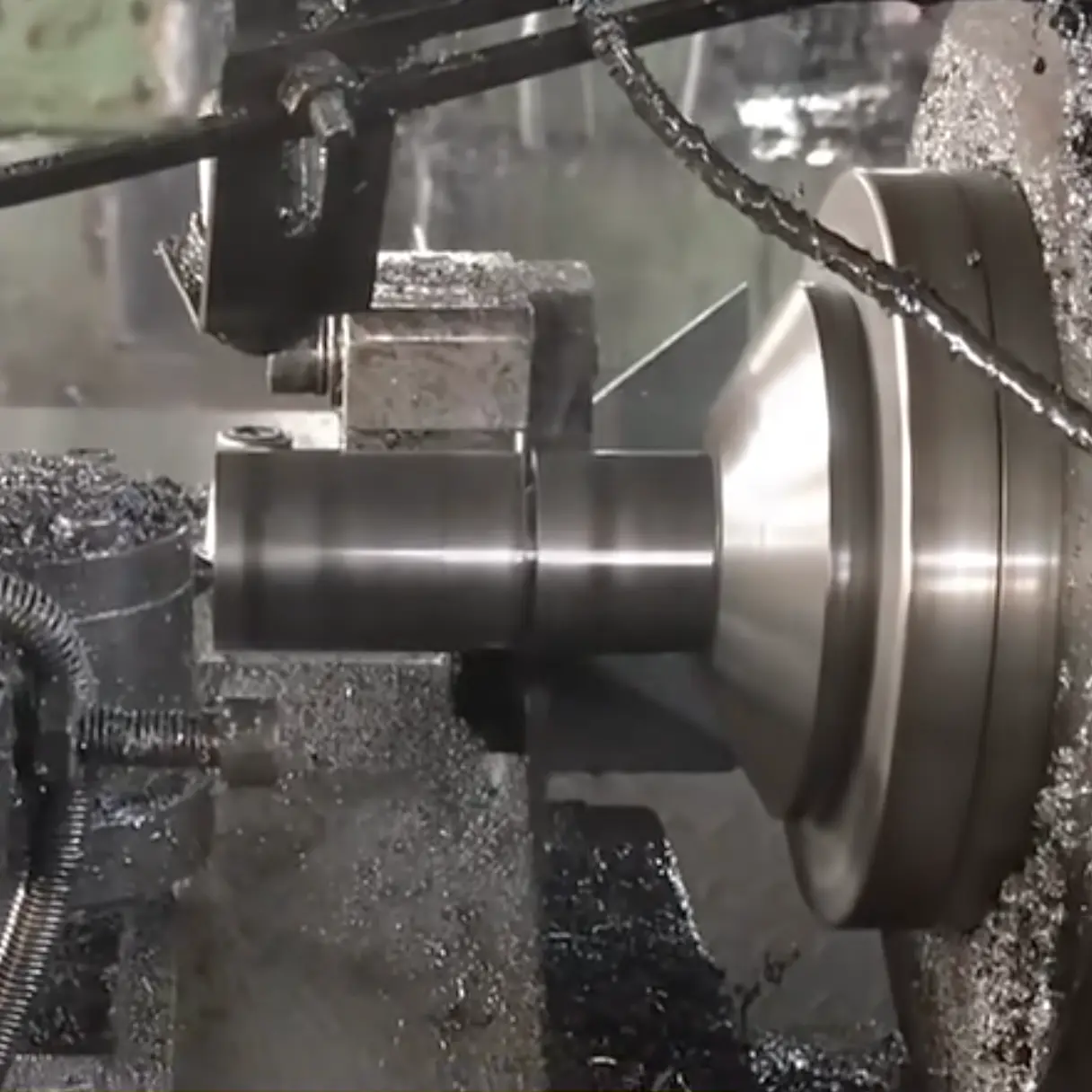

Product processing flow

1、Prepare raw materials

2、 Cutting

3、Stripping treatment

4、Sleeve tapping process

5、Stripping treatment

6、Finished rebar coupler

Quality Control and Certification

Each of our products has been certified by authoritative professional bodies, and we promise that all our high-quality services will give you peace of mind.

Upset Thread rebar coupler quality certification

Upset Thread rebar coupler quality certification

Product Packing

Our packaging uses woven bags and wooden pallets;

Protection of products

Use the protective cap to prevent dust and debris from entering the rebar coupler before installation.

- Upon arrival at the site, steel reinforcement sleeves shall be stacked with wooden spacers according to specification, model, and type. Raw steel materials must be stored in designated locations, while semi-finished steel reinforcement shall be stacked at least 300mm above ground level.

- All motorised machinery, including straightening machines, cutting machines, welding machines, bending machines, and straight thread rolling machines, shall be elevated and covered with protective rain shelters to prevent waterlogging.

- Before tying, remove any silt from the steel bars. Should rust be present, remove it before transporting the bars to the designated construction area for tying. Welding of steel bars is strictly prohibited during rainfall. Should rain occur during welding, immediately protect the welding rods and workpieces from exposure to rain.

- Threaded sleeves must be fitted with plastic protective caps immediately after threading to prevent damage or rusting. Any mud or sand must be thoroughly cleaned off.

- When operating steel processing machinery during rainy weather, work must be carried out within a processing shed.

Precautions for Use

- Reinforcing bar preparation: After upsetting the bars to be connected using a rebar upsetting machine, the ends must be straight and free of any curvature. Any curvature must be straightened. Failure to straighten the bars or inadequate threading will directly compromise connection quality and create safety hazards. When cutting bars, use a hacksaw or other suitable tool to ensure the cut ends are straight and perpendicular to the bar’s axis.

- Threaded End Processing: The threaded length should generally be half the sleeve length plus 1-2 threads. When processing threads, use the same thread profile and pitch as the coupling sleeve, employing water-soluble cutting lubricant.

- Connection procedure: When joining steel bars, align the axis and screw the bars into the coupling sleeve. Tighten using a torque wrench, which must be calibrated periodically. Cease work immediately if thread blockage occurs or thread ends fail to meet specifications.

- Quality Inspection: Processed threaded ends must undergo individual self-inspection using thread ring gauges. Non-compliant ends shall be cut off and reprocessed. After connection, verify that the reinforcement bars are fully seated and centred within the coupling sleeve.

- Protection and Storage: Upon completion of threading, immediately fit protective caps or screw on coupling sleeves. Coupling sleeves must be securely covered with reinforcement sleeve protective caps to prevent damage.