Steel Rebar Thread Rolling Machine

- We belong to the source factory

- High quality products are trustworthy

- Complete range of specifications

- Customization supported

Description

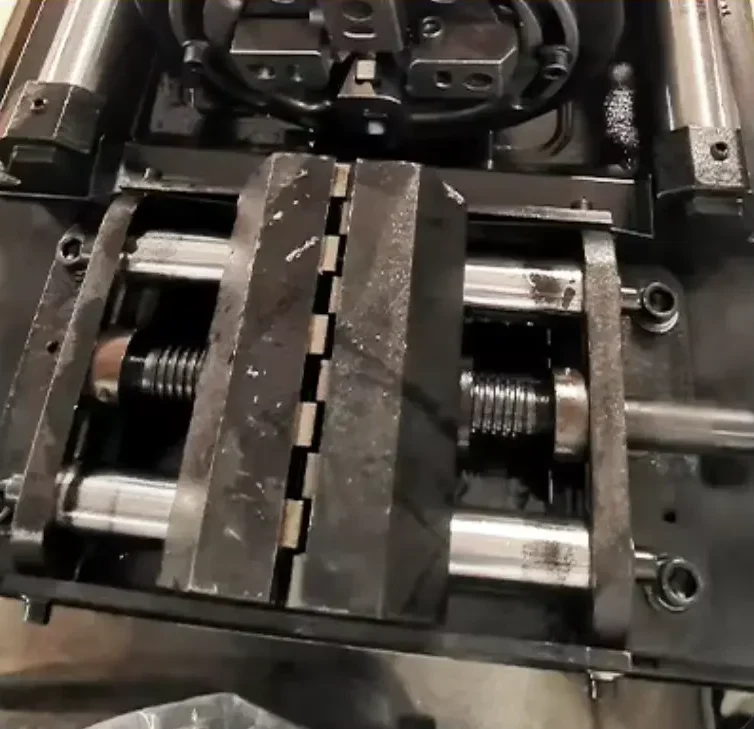

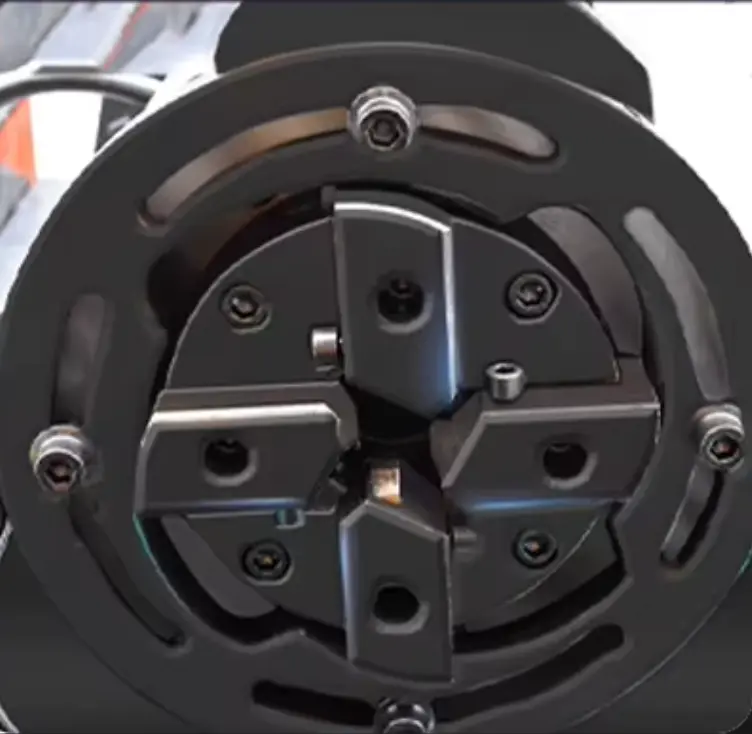

The fully automatic electric Steel Rebar Thread Rolling Machine is an intelligent device with digital control and display operation designed for the automatic threading of prestressed steel bars. It completes rib stripping and thread rolling in one operation, ensuring a complete and precise thread profile with high dimensional accuracy, providing a strong guarantee for the installation of straight thread steel bar sleeves. In addition, it can generate right-handed threads and left-handed threads.

Product Technical Parameters:

Steel bar processing diameter range: D14mm – D40mm

Processing steel bar length: 80 mm

Rolling angle: 60 °/75 °

Spindle speed: 76 r/min

Thread roller diameter: 79mm/71mm/61mm

Pitch: 2.5mm/3.0mm

Voltage: 380V/220V

Main motor power: 7.5KW (100% pure copper motor)

Total power: 7.5KW

Equipment weight: 600 kg

Dimensions (L × W × H): 1500 × 850 × 1300 mm

Product features:

Environmental Adaptability:

The fully automatic steel rebar thread rolling machine is suitable for complex and harsh environments. The entire threading process is operated via a display screen, which frees up manual labor, avoids environmental impacts on project progress, improves production efficiency, and is more energy-efficient and environmentally friendly.

Integrated Functionality:

The steel bar thread rolling machine can also be equipped with a cold-cutting saw, enabling rapid trimming and cutting to length of steel bars directly on the thread-rolling machine—this is more efficient than the conventional method of trimming and cutting steel bars individually.

Fully automatic steel bar threading machines are available in two types: pneumatic fully automatic threading machines and electric fully automatic threading machines.

Diverse Models

In the past, existing steel bar thread rolling machines required manual placement of steel bars into position, manual clamping, and subsequent manual movement of the machine itself. To achieve fully automatic processing of steel bar threads, it was necessary to implement functions such as automatic positioning, clamping, and movement for thread rolling. The fully automatic electric threading machine resolves this issue.

Product Advantage: