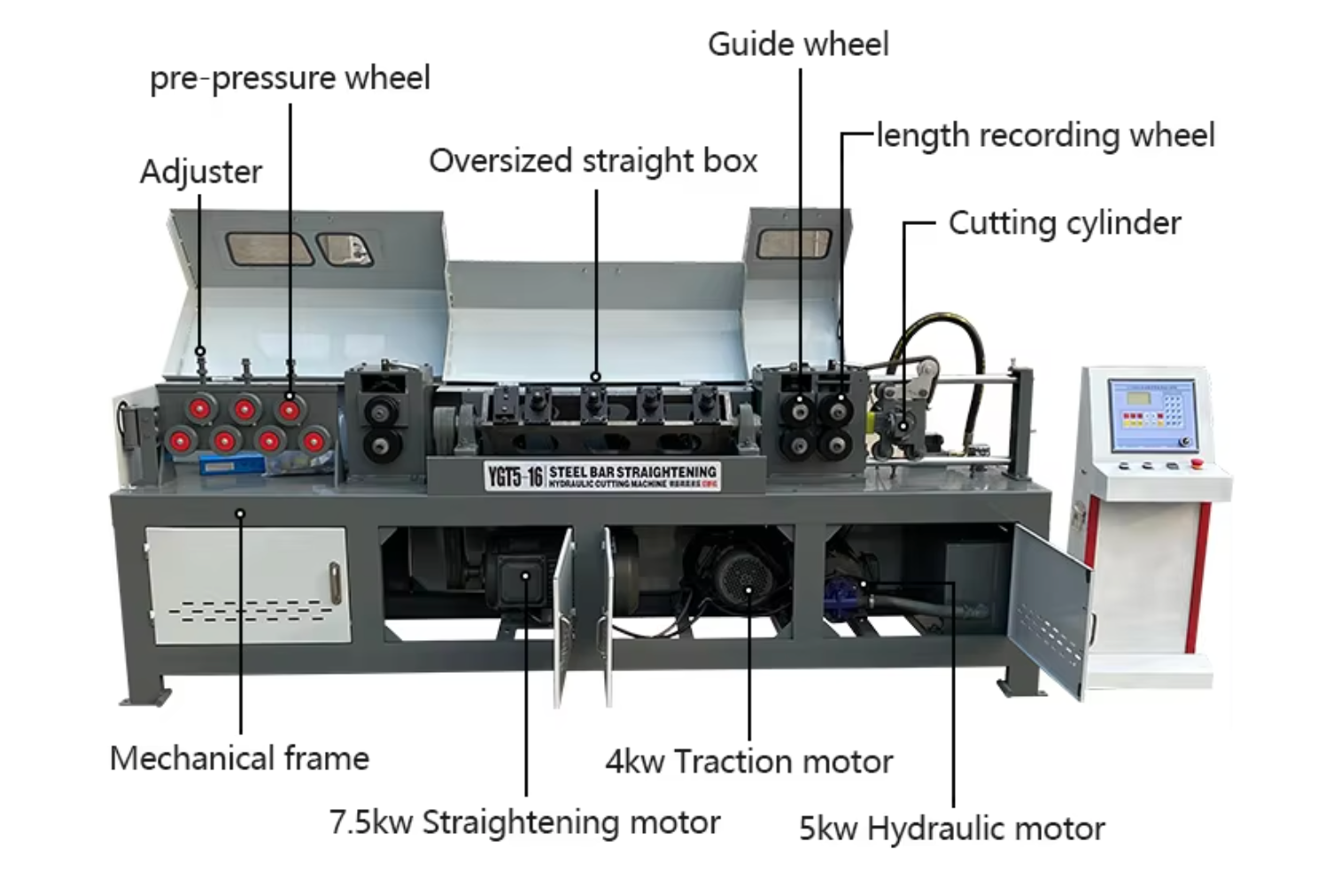

Steel bar straightening and cutting machine

Description

The steel bar straightening and cutting machine is a mechanical device used for straightening and cutting rebar, widely applied in construction, bridge, tunnel, and other engineering fields. It straightens bent rebar through mechanical or CNC methods and cuts it to the required length, ensuring the rebar’s straightness and dimensional accuracy. The main components of the rebar straightening and cutting machine include the straightening device, cutting device, feeding device, and control system.

Product Parameters

| Model | YGT5-16 |

| Original | China |

| Type | Straightener & Cutter |

| Brand Name | Anda |

| Voltage | 220V,Voltage can be made as customer request |

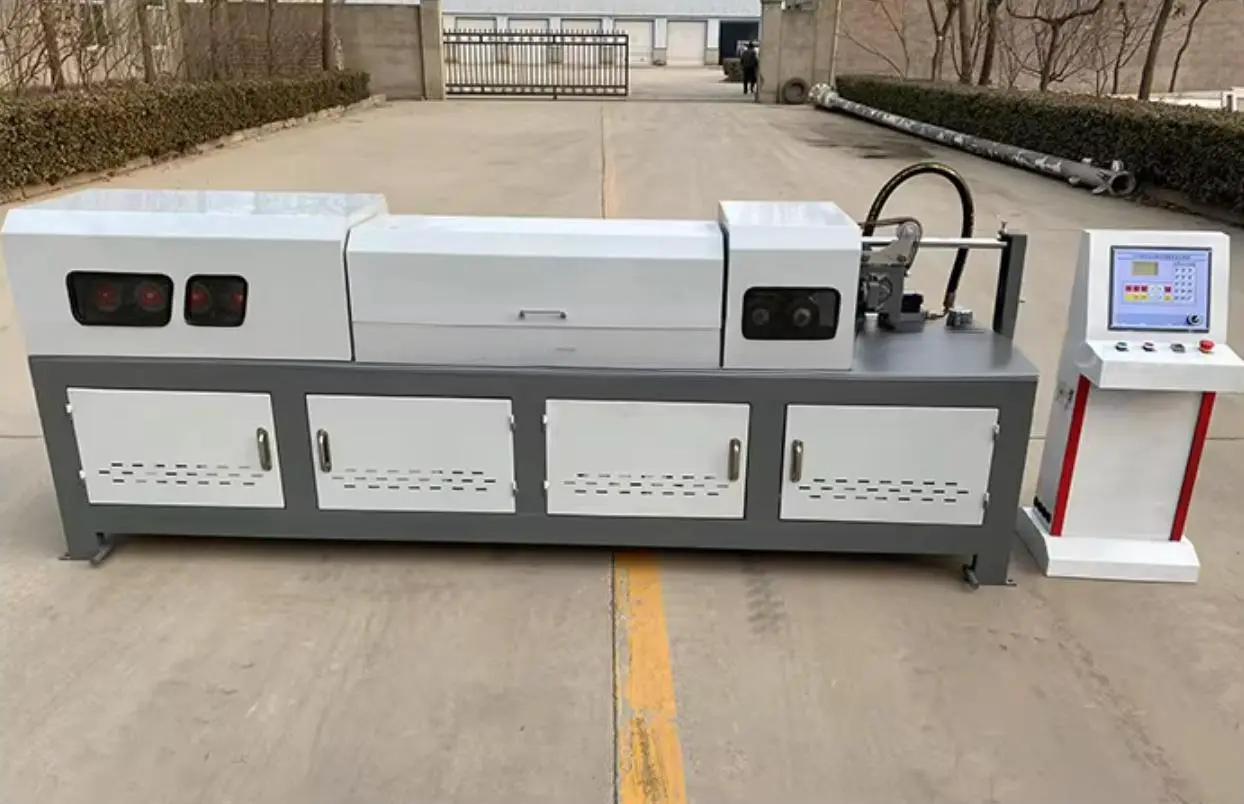

| Dimension(L*W*H) | 3300*850*1300mm |

| Weight (KG) | 1500 |

| Usage | Construction Works |

| Processing range | 4-14mm |

| Straightening motor power | 15kw |

| Tractor motor power | 4kw |

| Cutting motor power | 5.5kw |

| Voltage | 220v |

| Straightening Speed | 50-55m/min |

| Cutting length error | 0.5-1cm |

working principle

The working principle of the steel bar straightening and cutting machine is to bend and stretch the steel bars multiple times through the straightening wheel, eliminate their internal stress, and restore them to a straight state. Subsequently, the steel bars are fed into the cutting device and cut according to the preset length. The CNC steel bar straightening and cutting machine also has the characteristics of high automation, high precision, and high efficiency, which can greatly improve production efficiency.

Product Details

1. Accurate measurement

Built for longevity, the upgraded meter wheel is made of chromium-vanadium steel to deliver exceptional hardness and wear resistance, extending its service life.

2. Numerical control operation

High straightening efficiency, fully automatic NC operation, batch, length and quantity can be set.

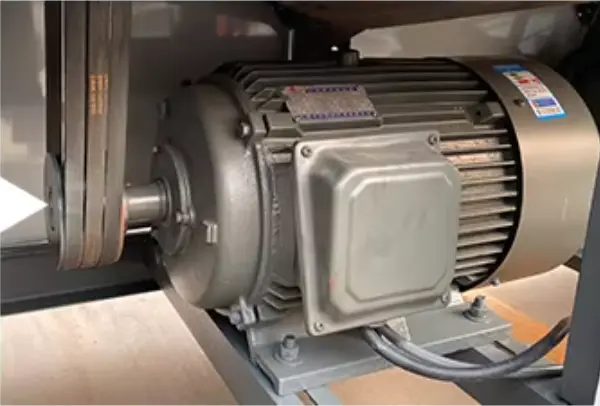

3. Pure copper motor

Pure copper coil, Higher efficiency, Better heat resistance, long service.

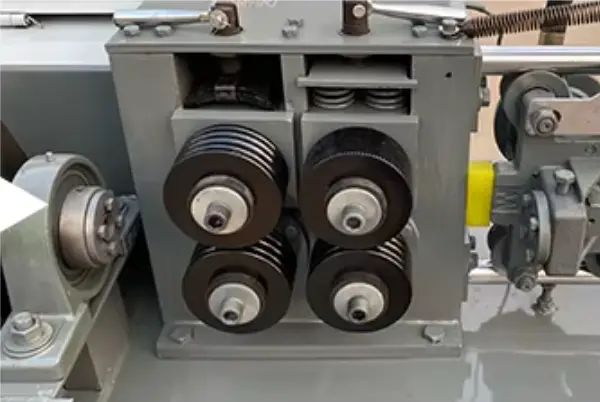

4. straightening frame

Thickened concentric straightening frame accurate cutting, 1440 revolutions perminute, rapid straightening.

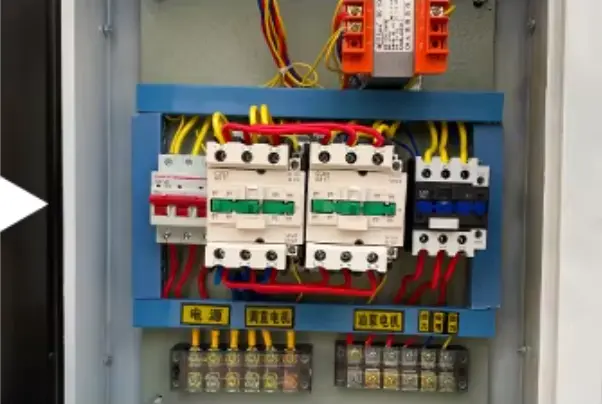

5. Brand frequency converter

After the dust-proof and waterproof test,it can preventelectrical damage causedby dust and fog.

6. simple operation

Adopt multi-directional guide wheel single-person easy operation, feed is easier.

Operation precautions

When operating a rebar straightening and cutting machine, observe the following operational procedures:

- Adjust the straightening blocks. Typically, the straightening cylinder contains five straightening blocks. The first and fifth blocks must be positioned on the centerline, while the middle three may be offset. Begin by setting the rebar offset to approximately 3mm. After trial straightening, if the rebar still exhibits a slight bend, gradually increase the offset until straightening is achieved.

- When straightening reaches the end of the rebar, personnel must stand clear to avoid injury from whipping motion. For rebar shorter than 2m or with a diameter greater than 9mm, operate at low speed.

- After cutting three or four rebars, stop the machine to verify length accuracy. Adjust the fixed-length plate as needed until dimensions are correct.

- Install a 1-meter-long rebar at the front of the guide tube. Pass the rebar through the steel pipe first, then into the guide tube and straightening tube to prevent it from springing out and causing injury as each coil nears the end of straightening.

- Do not feed rebar into the machine before securing the straightening block and properly covering the guard. This prevents injury from the straightening block flying out when the machine starts.

- Do not stack objects on the machine to prevent them from falling into the machinery. When loading steel bars into the pressure rollers, maintain a safe distance between hands and rollers. Do not adjust the rollers while the machine is operating. Gloves are prohibited during operation.

Application scenarios

Reinforcing bars are typically coiled into bundles for convenient transportation. Before use, they must be straightened using specialized equipment. Applications for rebar straightening and cutting machines include construction sites, rebar processing plants, and precast component factories. Their primary advantage lies in rapidly and accurately straightening and cutting rebar, reducing manual labor and enhancing work efficiency. Additionally, CNC rebar straightening and cutting machines feature user-friendly operation and easy maintenance.

When selecting a rebar straightening and cutting machine, key considerations include the diameter range of the rebar, straightening precision, cutting accuracy, as well as the equipment’s stability and durability.