Rebar Coupler Torque Wrench

Durable carbon steel construction ensures long service life.

Suitable for a wide range of industrial tightening tasks.

Offers customizable colors and ODM services to meet specific user needs.

Compact and multi-functional design ideal for professional and general use.

Description

The rebar coupler torque wrench, is a manual tool specifically designed for tightening or loosening straight thread rebar sleeves. It serves as an indispensable key tool in the modern construction industry for mechanical rebar connections (threaded connections).Its primary function is to deliver sufficient torque to the rebar sleeve, ensuring a tight connection with the threaded rebar end. This securely joins two rebars together, enabling the transfer of forces. This connection method replaces traditional welding and lap splicing, offering advantages such as high strength, rapid efficiency, and consistent quality.

Parameters of Rebar Coupler Torque Wrench

- Product Name: Rebar Coupler Torque Wrench

- Material: High-strength Carbon Steel

- Grade: Industrial

- Place of Origin: Heibei, China

- Thickness: 1/2 inch

- Jaw Capacity: 15/16 inch

- Available Sizes: 18 inches / 450mm & 24 inches / 650mm

- Pipe Diameter: 27mm, 32mm

- Max Working Diameter: 40mm, 50mm

- Color: Customized Color Support

- Customization: ODM Supported

- Application: Industrial Multi-Purpose Tool

- Minimum Order Quantity (MOQ): 1 piece

Feature Highlights:

Durable Construction: Made from carbon steel with nickel coating, ensuring long-lasting performance in industrial and multi-purpose applications.

Versatile Sizing: Available in sizes ranging from 18 to 24 inches, with jaw capacities of up to 15/16 inches.

Customization Options: Custom colors and OEM services are supported to meet specific requirements.

Convenient Logistics: Secure payment terms and global shipping services are provided.

Rebar Coupler Torque Wrench Operation Steps:

Adjust the Torque Setting

Locate the small key at the grip of the torque wrench handle.

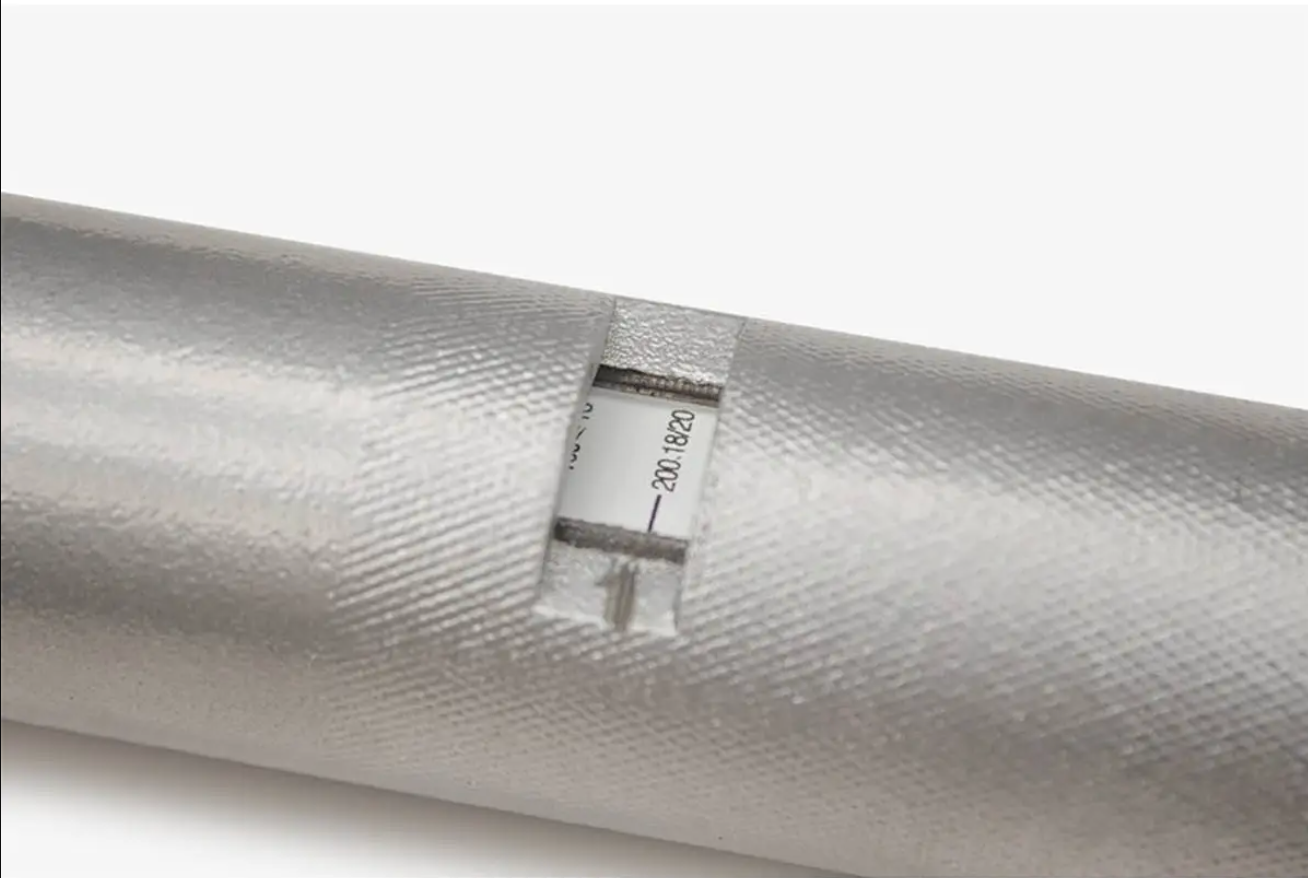

Use a small key ring to turn the key until the numbers displayed in the long rectangular window move upward or downward.

Set the Required Torque Value

When testing a #16 rebar coupler, adjust the key until the reference scale line aligns with the value “-80 ≤16” in the display window.

Perform the Test

Attach the head of the torque wrench securely to the rebar coupler.

Apply appropriate force by pressing the torque wrench steadily.

Interpret the Results

If you hear a “pop pop” sound, the #16 rebar coupler meets the required torque standards.

If no sound occurs, the fixing force of the coupler does not comply with testing requirements.

General Note

The same procedure applies to testing other rebar couplers of different sizes or under similar conditions.

User Manual: Torque Wrench Safety & Operating Guidelines

- Keep the wrench handle free of water, mud, sand, or other debris. Do not use the torque wrench as a hammer.

- During use, keep the jaw head level and apply force evenly. Avoid sudden or impact forces.

- When you hear a “click” sound from the wrench, stop pulling immediately. Continuing to apply force may damage the measuring mechanism.

- If the wrench will not be used for an extended period, reset the torque value to zero to prevent fatigue and loss of accuracy in the force-sensitive components.

- Never use the wrench when the torque setting is at zero. In this state, no audible signal will sound when the torque is reached, which can lead to overload and damage.

- If the wrench fails to produce an audible “click” during use, stop operation immediately and arrange for repair. The wrench must be recalibrated before reuse after any repair.