Rebar Cold Extrusion Press Machine

Description

Rebar Cold Extrusion Press Machine employ hydraulic or mechanical pressure at ambient temperatures to place two steel bars within a cold extrusion press sleeve. By compressing the steel sleeve through the cold extrusion process, the bars are tightly bonded, joining their ends into a single unit. This equipment finds extensive application in reinforced concrete construction, high-rise frame buildings, highways and railways, tunnels and bridges, airport development, flood defence embankments, and seismic engineering projects.

Product Advantages

1. Connection quality is stable, reliable and consistent, ensuring the joint possesses equivalent strength to the base material.

2. Compared to conventional welding processes, efficiency is enhanced by over threefold.

3. Operation is straightforward; operators require only basic training or instruction manual review before commencing work.

4. The rebar cold extrusion press machine for reinforcing bars operates independently of environmental constraints and weather conditions, presents no fire hazard, eliminates arc glare exposure and conserves electrical power.

5. Compared to various threaded rebar connection methods, it offers superior usability and versatility with lower overall operating costs. It currently represents the highest-performance, most stable joint configuration among all rebar connection types. Compact and lightweight, this equipment utilises a high-pressure electric oil pump specifically manufactured by our factory for the JYJ-32/40 model as its power source. Its flexible operation makes it suitable for on-site construction and elevated work.

Product Specifications

| motor power | 4KW |

| rated voltage | 380V / 50hz |

| Working stroke | 45mm |

| Working pressure | 63Mpa |

| Crimp size | 12mm-32mm |

| Weight | 125kg |

Safety Operating Procedures for Rebar Cold Extrusion Press Machine

1. Calibration of the extruder’s pressing force shall be performed when any of the following conditions apply:

- Before using new extrusion equipment;

- After major overhaul of old extrusion equipment;

- Following damage to the pressure gauge or severe vibration;

- When abnormal sleeve indentations occur with no other identifiable cause;

- After the extrusion equipment has been in use for over one year;

- When the number of extruded joints exceeds 5,000.

2、During the assembly and disassembly of equipment before and after use, the connectors at both ends of the ultra-high-pressure oil hoses, along with the crimping pliers and the inlet/outlet connectors of the directional control valve, must be kept clean and promptly sealed with dedicated dust caps. The bending radius of the ultra-high-pressure oil hoses must not be less than 250mm. The crimped joints must not be twisted, and no sharp kinks are permitted.

3、Pressure gauges shall be inspected periodically, with measurement errors not exceeding 5%.

4、High-pressure hoses within the extruder’s hydraulic system must not be subjected to load-bearing dragging, bending, or abrasion by sharp objects.

5、Moulds, casings and reinforcing bars shall be used in matching sets. Moulds shall bear corresponding reinforcement bar specification markings.

6、Preparatory work prior to extrusion:

- Rust, mud, oil, and other contaminants on rebar ends must be thoroughly cleaned;

- Rebars and sleeves shall undergo trial fitting beforehand. Should rebar exhibit horseshoe bends, kinks, or excessive longitudinal rib dimensions, pre-correction or grinding with a grinding wheel is required; sleeves for different rebar diameters must not be interchanged;

- Positioning and inspection marks shall be marked on the rebar ends. The positioning mark shall be located at half the sleeve length from the end, while the inspection mark should be positioned 20mm from the positioning mark.

- The compression equipment shall be inspected and subjected to a test run. Work may only commence once it meets the required standards.

7、Extrusion operations shall comply with the following requirements:

- Reinforcing bar compression connections should preferably involve compressing one sleeve end on the ground first, then inserting the bars to be joined at the construction site before compressing the other sleeve end;

- When positioning the crimping tool, align it with the markings indicating the sleeve indentation location and maintain perpendicularity to the rebar axis;

- The crimping sequence should commence from the centre of the sleeve and progress gradually towards the ends;

- Operators must not arbitrarily alter the crimping force, number of crimping passes, or crimping sequence.

8、After completing the task, tidy away the finished products, sleeves and moulds, clear the work area, switch off the power supply, lock the switch box, and finally return the extruder and extrusion pliers to their designated locations.

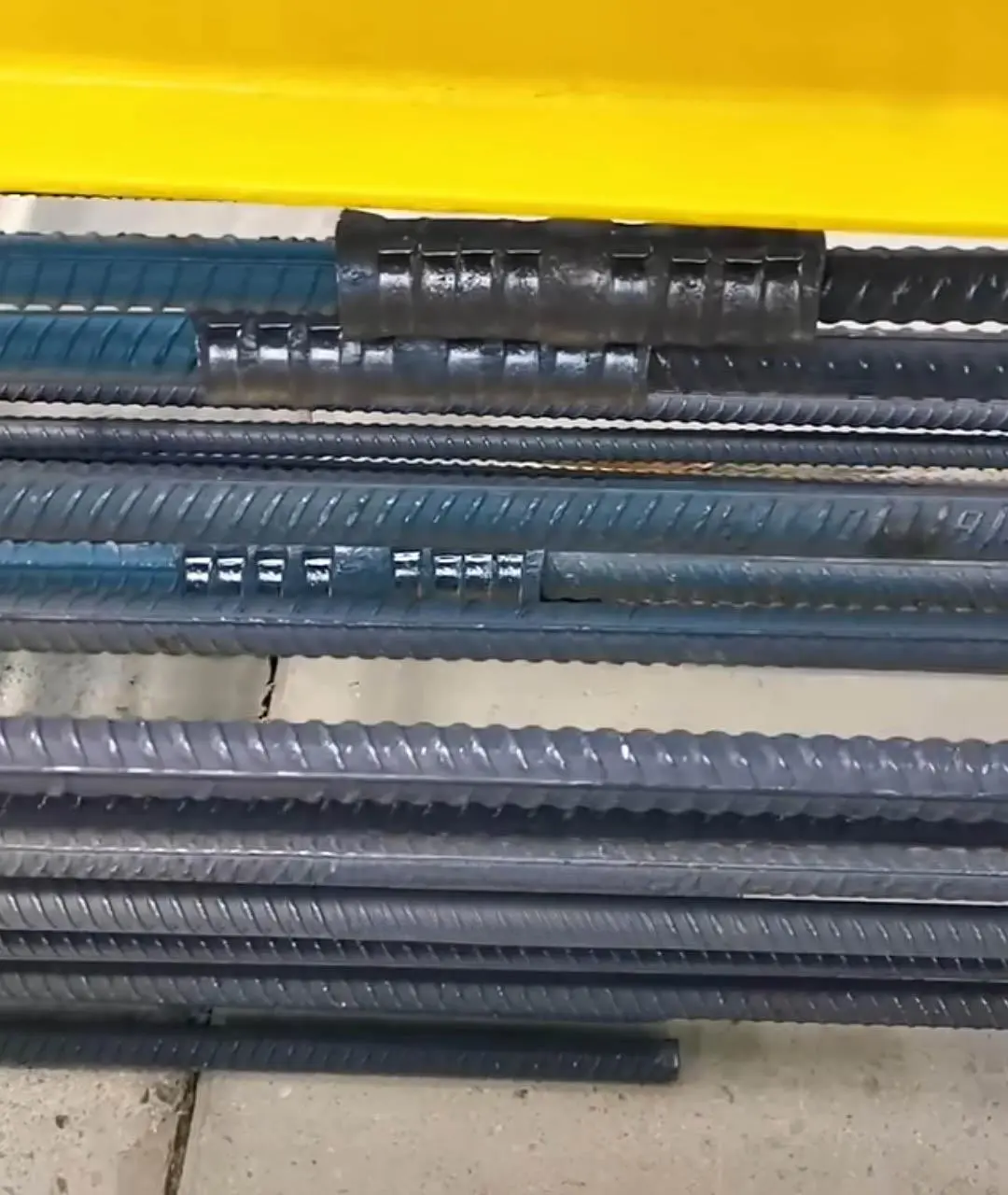

Processing Effect of the Rebar Cold Extrusion Press Machine

Project case

Fu xia high railway project

ZhangJinggao Yangtze River Bridge

Nanjing Metro Line 7