rebar coupler for metro – Xi’an Metro Line 6 Project

As a critical rebar coupler for metro and similar underground engineering projects, this technology plays a pivotal role in ensuring structural integrity. Xi’an Metro Line 6, serving as the backbone route traversing the ancient city of Xi’an from east to west, faces multiple challenges including complex geological conditions, cultural heritage preservation requirements, and stringent seismic resistance standards. These demands place exceptionally high requirements on reinforcement connection technology.

As one of the suppliers of rebar couplers for Xi’an Metro Line 6, Hengshui Anda Machinery Equipment Co., Ltd. will comprehensively analyze the specific application of rebar coupler technology across various project phases of Xi’an Metro Line 6. Drawing on project experience, this analysis will cover everything from station main structures to shield tunnel sections, and from material selection to process innovation, demonstrating how this technology ensures the quality and progress of metro construction while meeting Xi’an’s unique geological and seismic requirements. Through in-depth analysis of specific construction cases and technical specifications, this analysis will reveal the critical role of rebar sleeve technology in subway construction and its future development trends.

Overview of Xi’an Metro Line 6

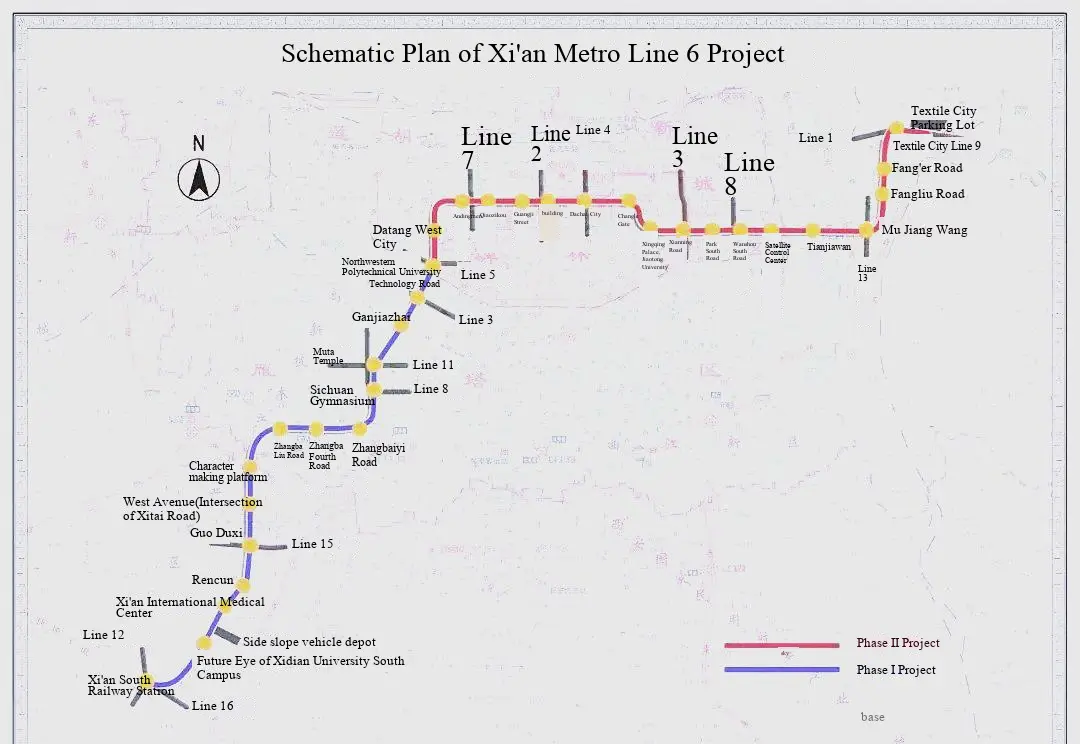

Xi’an Metro Line 6 is the seventh major line to be completed and put into operation within Xi’an’s urban rail transit network, constructed in two phases. Phase I (Xi’an South Railway Station–Northwest Polytechnic University Station) commenced construction on March 28, 2016, and began operations on December 28, 2020. Phase II (Northwest Polytechnic University Station–Textile City Station) started construction on January 9, 2017, and officially opened at the end of 2022. This 19.5-kilometer metro line features 17 underground stations, including 6 transfer stations. It traverses the High-Tech Zone, connects areas such as Chang’an, Beilin, and Yanta, and terminates at Textile City Station, thereby enhancing the backbone network functionality of Xi’an’s metro system.

1. Construction Challenge

- The route passes through cultural heritage sites such as the Bell Tower, requiring special consideration for the impact on historical structures during construction.

- Xi’an is located in a high-intensity seismic zone with seismic fortification intensity reaching 8 degrees (0.20g), imposing extremely high demands on the robustness and stability of building structures.

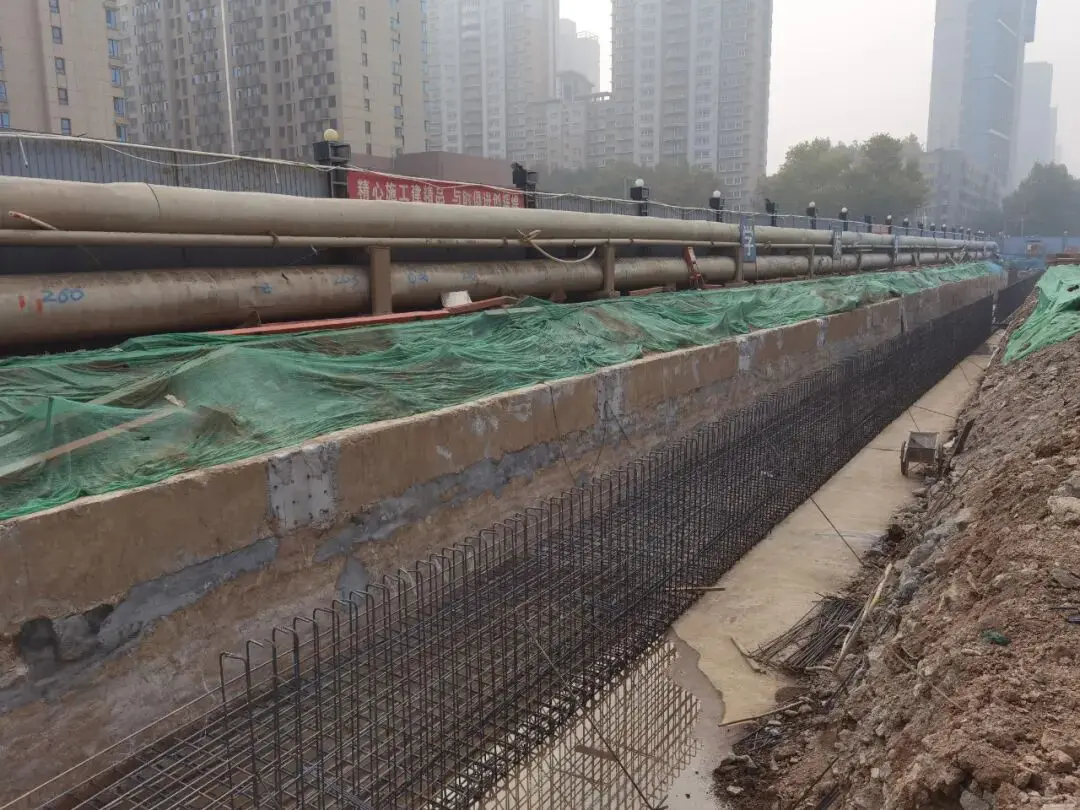

- Complex and variable geological conditions prevail in Xi’an, characterized by widespread collapsible loess. This soil type exhibits a drastic reduction in strength when saturated with water, leading to significant settlement. This poses a serious threat to the stability of excavation slopes and the structural integrity of tunnels. Rigorous foundation treatment, dewatering, and waterproofing measures are imperative.

These factors collectively necessitate the adoption of high-standard steel bar connection technology for Xi’an Metro Line 6 to ensure structural integrity and seismic performance.

2.Advantages of Steel Bar Sleeve Connections

Traditional rebar connection methods, such as lap splicing and welding, suffer from numerous limitations, including inconsistent joint strength, low construction efficiency, and significant quality fluctuations. In contrast, rebar sleeve connection technology achieves force transfer between bars through mechanical interlocking, offering distinct advantages such as high connection strength, stable quality, rapid construction speed, and strong adaptability. This makes it particularly suitable for large-scale underground projects like Xi’an Metro Line 6. Hot-rolled ribbed steel bars are extensively used in subway construction, with material standards strictly adhering to GB/T 1499.2-2007/1-2009 “Steel for Reinforced Concrete – Part 2: Hot-Rolled Ribbed Steel Bars.” This provides an excellent base material for sleeve connections.

3. Geological challenges drive technological innovation

Xi’an Metro Line 6 is not only extensive in terms of route length and number of stations, but also represents significant construction challenges. The line traverses diverse complex geological conditions, particularly in sections like the one between Convention Center Station and Laotun Station, where challenges include intricate geological environments and extended tunnel lengths. These engineering characteristics compelled builders to innovate in rebar connection techniques, adopting multiple advanced methods—including straight thread couplers—to meet the diverse rebar connection demands across different project sections and construction environments.

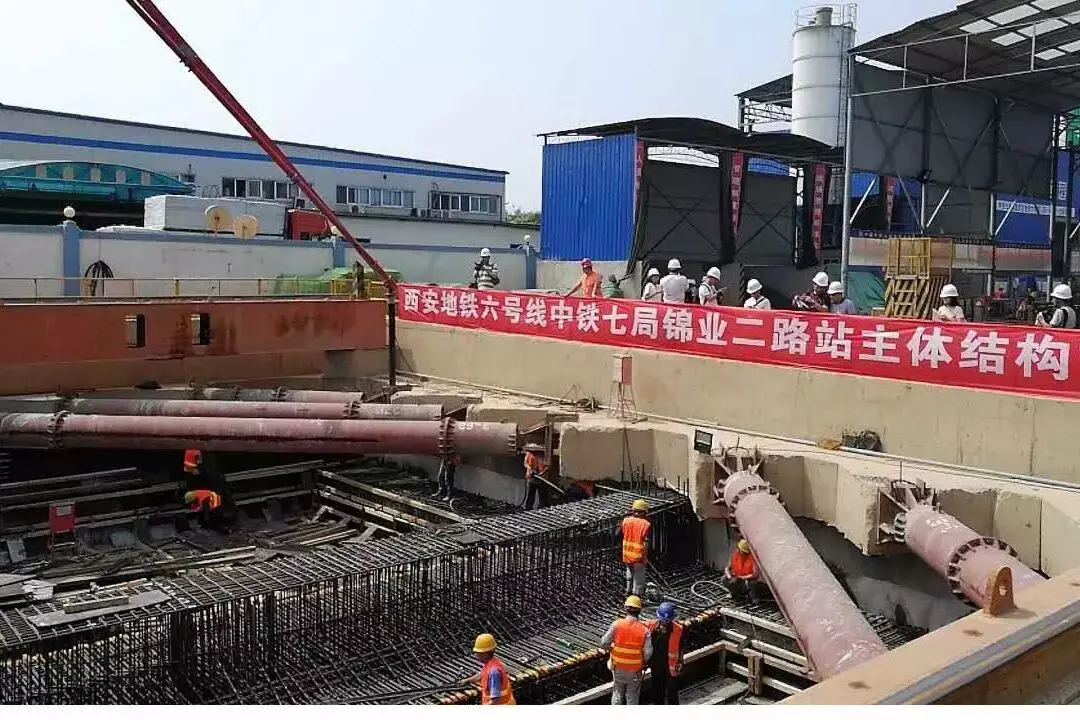

Key Applications in the Main Structure of the Station

The construction of stations along Xi’an Metro Line 6 extensively utilized rebar sleeve connection technology, which played an irreplaceable role in ensuring structural integrity and enhancing construction efficiency. Taking Nanke Station on Phase I of Line 6 as an example, this underground island platform station features two levels with partial third-level sections. The station building spans 378.3 meters in length, with a standard segment width of 22.6 meters and a total floor area exceeding 21,564 square meters. Its rebar engineering volume is substantial and structurally complex. Within such large-volume concrete structures, the rebar sleeve connection technology resolved construction challenges in densely reinforced zones caused by traditional lap splicing methods, effectively ensuring the load-transferring performance of structural nodes.

Straight Thread Reinforcing Bar Coupling Technology

During the main structure construction of the station, the project team primarily employed straight thread rebar sleeve connection technology. This technique was systematically applied at stations such as Guangji Street Station under Contract TJSG-16 of Xi’an Metro Line 6 Phase II. The process principle of straight thread sleeve connections involves: machining the ends of two connecting steel bars into straight threads via a rolling process, then interlocking these ends using specialized straight thread sleeves. Stress transfer is achieved through the mechanical interlocking force of the threads. Compared to traditional welding or lap splicing, this connection method offers multiple advantages: high connection strength (achieving the strength of the parent steel bar material), fast construction speed, weather independence, elimination of open-flame operation safety hazards, and low energy consumption, aligning with green construction principles.

Quality Control System

In the specific construction process, the rebar coupler for metro application in Xi’an Metro Line 6 reflected a strict quality control system.

- Prior to construction, all raw steel reinforcement materials must undergo verification of quality assurance certificates, factory compliance certificates, and other documentation. Materials shall be managed by batch, specification, furnace number, and manufacturer.

- Technicians processing steel reinforcement must receive specialized technical training and pass assessments before being permitted to work. Personnel allocation shall remain relatively stable to ensure process consistency.

- The construction site is equipped with specialized tools including threading machines, pipe wrenches, torque wrenches, and cutting machines to enable precise control over each process step. Crucially, the project team conducted a specialized study on “Quality Control of Straight Thread Coupling Installation” through QC group activities. This initiative optimized construction techniques, standardized operational procedures, and specifically addressed common quality issues such as incomplete thread grinding and inaccurate torque control. The achievement was honored as a Category III Outstanding QC Group Activity in Xi’an’s 2024 Engineering Construction Awards.

| Sleeve Type | Technical Features | Typical Application Area | Advantages |

| Standard Coupler | Conventional length, full-thread connection | Station walls, main reinforcement of floor slabs | High connection strength, convenient construction |

| Extended Coupler | Increased length, convenient for pre-installation with full-thread insertion | Dense reinforcement areas, long rebar connections | Solves the problem of insufficient rotation space |

| Lock Nut Coupler | Equipped with lock nut to prevent loosening | Bent rebar joints, critical load-bearing parts | Adaptable to non-axial stress conditions |

| Transition Coupler | Connects rebars of different diameters | Structural cross-section change areas | Enables reliable connection of rebars with different diameters |

Primary Types and Application Locations of Reinforcing Bar Couplers in Xi’an Metro Line 6 Station Construction

High-intensity seismic design requirements

To meet Xi’an’s high seismic design requirements (Magnitude 8, 0.20g), steel bar connection nodes in subway stations must possess excellent seismic performance and deformation capacity. Reinforcing bar sleeve connections ensure strength and ductility in the joint zone through standardized processes, eliminating the risk of brittle failure associated with welding. Particularly at critical locations such as the junction between station ceiling slabs and side walls, and at column-beam connections, the use of sleeve connections guarantees effective stress transfer, enhancing the overall seismic performance of the structure.

Pre-embedded rebar Sleeve Technology in Shield Tunneling Sections

1.Technical R&D and Innovation Breakthroughs

During the construction of Xi’an Metro Line 6, the project team established a dedicated technical task force focused on overcoming core challenges through innovative breakthroughs. By optimizing shield tunneling parameters and developing new synchronous grouting materials, they successfully controlled ground settlement to within 3 millimeters, ensuring the safety of surrounding structures.

2. High-Precision Connections in Segmental Production

Reinforcement sleeve connection technology plays a critical role in the production of shield tunnel segments. To meet the stringent requirements for structural strength and dimensional accuracy of the segment reinforcement framework, the project adopted straight-thread sleeve connection technology. This factory-prefabricated method ensures consistent quality at every reinforcement connection node, laying the foundation for seamless segment assembly. Consequently, it guarantees the integrity and waterproofing performance of the tunnel structure.

3.Connection Scheme for Special Structural Nodes

At the interface between shield tunnel sections and stations, the complex structure, dense reinforcement, and varying stress directions present significant connection challenges. To address this, the project employs extended-length or lock-nut-type connection sleeves. These specialized sleeves enable reliable connections even when reinforcement cannot be rotated, ensuring effective stress transfer from the tunnel structure to the station structure. This is particularly crucial for maintaining the line’s structural continuity and overall seismic performance.

4. Design philosophy for the entire life cycle

The application of pre-embedded sleeve technology in subway engineering embodies a systematic approach encompassing the entire lifecycle of design, construction, and operation and maintenance.

- Construction Phase: This technology enables precise positioning during segment jointing and provides reliable pre-embedded connection points for subsequent MEP installations.

- Operation and Maintenance Phase: Unlike traditional post-installed anchors that require destructive drilling into precast segments, the embedded sleeves are precisely installed during segment fabrication. This enables direct utilization during subsequent installations, significantly reducing interference with the tunnel structure. It protects the waterproofing system, extends the tunnel’s service life, and aligns closely with the sustainable development goals of subway construction.

As a vital component of Xi’an’s urban rail transit network, the construction quality of Xi’an Metro Line 6 directly impacts the reliability and safety of this century-long project. During the application of rebar sleeve technology, the project team established a rigorous quality control system and technical management process to ensure every rebar connection node meets design requirements and engineering standards. This system encompasses multiple stages including material selection, process control, personnel training, and acceptance inspections, forming a comprehensive, end-to-end quality management model.