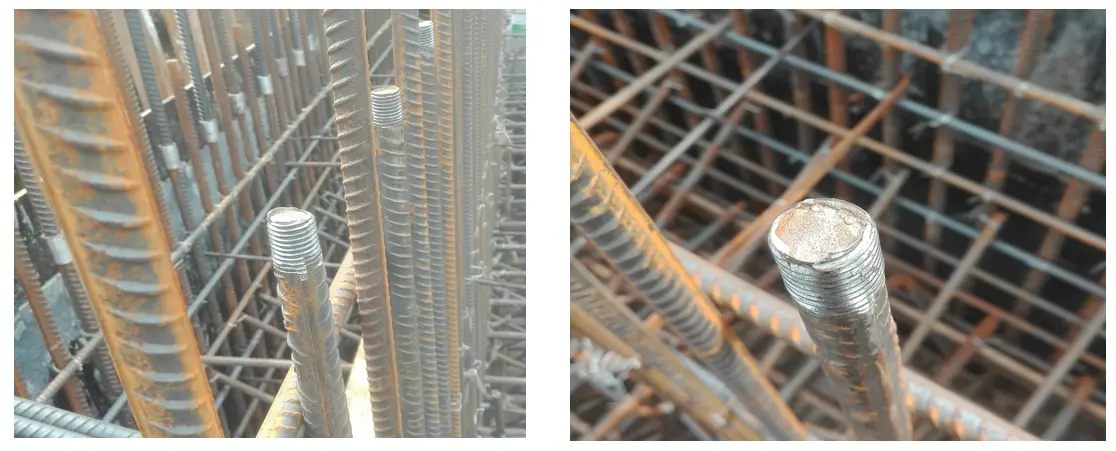

Straight Threaded Rebar Coupler

Specialized Product: Grade IV sleeves for stronger HRB500 rebar; larger than Grade III sleeves.

Certified Quality: Meets standards JG/T163-2013 & JGJ107-2016; multiple specs tested & certified.

Wide Application: Connects rebar horizontally, vertically, diagonally in buildings & infrastructure.

Reliable Performance: Ensures secure connections in all orientations for structural integrity.

Description

Reinforcing bar straight threaded rebar coupler are widely used in high-rise buildings, high-speed railways, subways, bridges, and other engineering projects. Their features include high strength, stable and reliable connection quality, convenient construction, fast connection speed, and excellent environmental performance.

Threaded Rebar Coupler Specification

Size | Outer Dia (mm) | Thread Angle | Length (mm) | Inner Dia (mm) | Thread Pitch |

D12 | 19.0 | 60 | 28 | 10.28 | 1.75 |

D14 | 21.0 | 75 | 32 | 12.55 | 2.5 |

D16 | 24.0 | 75 | 36 | 14.50 | 2.5 |

D18 | 27.0 | 75 | 41 | 16.35 | 2.5 |

D20 | 30.0 | 75 | 45 | 18.45 | 2.5 |

D22 | 32.5 | 75 | 49 | 20.35 | 2.5 |

D25 | 37.0 | 75 | 56 | 23.25 | 3.0 |

D28 | 41.5 | 75 | 62 | 25.95 | 3.0 |

D32 | 47.5 | 75 | 70 | 30.15 | 3.0 |

D36 | 53.0 | 75 | 78 | 33.85 | 3.0 |

D40 | 58.5 | 75 | 86 | 37.55 | 3.0 |

Straight Threaded Rebar Coupler advantage

Tensile strength ≥1.10 times actual or standard rebar strength.

Excellent fatigue resistance; passed two million cycle test.

Saves material; sleeve weight only 25% of extrusion type.

Factory processing, fast on-site assembly, no schedule delay.

Simple process; rib removal and threading in one operation.

Wide application; connects 14–40mm rebars in any orientation.

Safe and eco-friendly; noise-free, flame-free, dust-free.

Low energy use, -40°C performance, all-weather construction.

Product Raw Materials and Processes

Main Raw Materials

The direct raw material for parallel thread rebars coupler is medium- and large-sized construction steel, characterized by longitudinal and transverse ribs on the surface. It is classified into grades such as HRB335, HRB400, and HRB500, according to yield strength.

Manufacturing Processes

- Forging or Cold Rolling Forming: Steel bars are forged or cold-rolled to produce coupler blanks.

- Thread Processing: Internal threads are machined using a thread rolling machine or lathe (to match the rebar end threads).

- Heat Treatment (Optional): High-strength couplers undergo quenching and tempering to enhance performance.

- Surface Treatment: Anti-rust coating (e.g., galvanization) or oxidation treatment.

straight threaded Rebar Coupler Production Line

Quality Control and Certification

Each of our products has been certified by authoritative professional bodies, and we promise that all our high-quality services will give you peace of mind.

Working principle

The rib-peeling rolled straight threaded coupler is a type of joint formed by the meshing of straight threads—produced by peeling and rolling the end of a steel bar—with the threads of a connecting element (sleeve).

The sleeve length is generally required to be greater than twice the diameter of the steel bar.

Powerful partners

Project case

Xiong’an New Area Comprehensive Pipe Gallery

Beijing Daxing International Airport

Beijing metro Line 12

Installation diagram of straight threaded rebar coupler

Tool for installing straight threaded rebar sleeves

Frequently Asked Questions

The rebar end face has not been ground, and the hoof-shaped deformation has not been removed

The rebar end face has not been ground, and the hoof-shaped deformation has not been removed

The exposed effective threads of the straight thread rebar coupler are significantly more than two thread pitches.

In the installed straight thread rebar coupler, one end shows excessive exposure of effective threads, whereas the other end shows no thread exposure.