High-Strength cold extrusion press rebar coupler

Reliable performance: Provides strong, consistent joints with excellent fatigue resistance for reinforced concrete structures.

Wide range of applications:Versatile coupler suitable for various diameters and construction conditions.

Applicable projects: Trusted rebar connection solution for bridges, tunnels, high-rises, and large infrastructure projects.

Description

Anda High-Strength cold extrusion press rebar coupler are made of high-quality 20 carbon structural steel and feature high strength characteristics, enabling them to connect rebars with diameters ranging from 16 to 40 mm. They are the ideal solution for quickly connecting ribbed rebars.

Cold press rebar couplers are widely used in the construction of bridges, tunnels, high-speed rail projects, and other infrastructure projects.

Product Specifications

| Cold Extrusion Press Rebar Coupler | |||||

| Size | Diametr | Thickness | Length | Weight(kg/pcs) | Material |

| 12 | 24 | 5 | 100 | 0.23 | Q345B |

| 14 | 27 | 5 | 100 | 0.31 | Q345B |

| 16 | 30 | 5 | 120 | 0.37 | Q345B |

| 18 | 34 | 5.4 | 120 | 0.46 | Q345B |

| 20 | 36 | 5.6 | 120 | 0.53 | Q345B |

| 22 | 40 | 6.4 | 130 | 0.714 | Q345B |

| 25 | 45 | 7.5 | 160 | 1.010 | Q345B |

| 28 | 50 | 8 | 180 | 1.480 | Q345B |

| 32 | 56 | 9 | 190 | 2.000 | Q345B |

| 36 | 63 | 11 | 210 | 3.200 | Q345B |

| 40 | 70 | 12 | 240 | 4.300 | Q345B |

Technical Specifications and Performance

Tensile Strength:Greater than or equal to 1.10 times the actual strength or standard strength of the reinforcing bar.

Fatigue Performance:Excellent performance in 2 million fatigue strength tests

Low Temperature Performance:Passed low temperature test at -40 °C;

Product advantages:

- Neutrality, stable performance, and high connection joint strength;

- Easy to operate, fast speed, and improved work efficiency;

- No sparks or toxic gases are produced, avoiding air pollution and damage to waterproof sheets, and minimizing the possibility of fire;

- The sleeve is small in size, light in weight, energy efficient, and economical, and can be purchased and prepared in bulk;

- it saves steel and has good economic benefits.

Product comparison:

| Dimension | Cold Extrusion press rebar couplers | Straight Thread Sleeve | Traditional Welded Connection |

| Connection Principle | High-pressure plastic deformation forces sleeve to grip rebar ribs | Rebar ends are cold-rolled with straight threads and screwed into sleeve | Arc melts parent metal and electrode to form weld seam |

| Joint Strength | 1.05–1.15 × parent bar strength, excellent ductility | ≥ 1.1 × parent bar strength, slightly higher yield | 0.85–1.0 × parent bar, risk of brittle failure |

| Quality Consistency | One-step forming, quality governed by hydraulic pressure – highly stable | Thread accuracy dominates; more field variables | Highly dependent on welder skill, current stability, weather |

| Field Efficiency | 20–40 s per joint, no cooling time | 45-60 s for on-site threading + 15 s to screw in | 3–8 min incl. pre-heat, welding, cooling |

| Equipment Cost | Hydraulic pump, dies, jaws – high initial outlay | Threading machine + sleeves – moderate | Welding machine, cables, gas – low initial |

| Site Conditions | No open flame/sparks, works in tunnels or rain | No flame, but needs power for threading machine | Requires wind/rain protection & fire watch |

| Material Fit | HRB400/500 hot-rolled ribbed bars | HRB400/500; high-strength steels need verification | Almost any weldable rebar, but alloy sensitive |

| Testing Methods | Visual + random tensile test | Visual + random tensile test | Visual, UT, RT, tensile |

| Long-Term Durability | No heat-affected zone, superior fatigue & corrosion resistance | No heat-affected zone, superior fatigue & corrosion resistance | HAZ embrittlement, reduced fatigue life |

| Overall Cost | High equipment amortization, low consumables – economical on large volumes | Medium equipment, higher sleeve cost | High labor/consumables, low consumable cost per joint |

Product Raw Materials and Processes

1、Raw materials: ML35 steel is used, which has excellent cold working properties and high purity, making it the mainstream and preferred material. It is suitable for most specifications of rebar connection sleeves.

2、manufacturing process:

- Cutting: Precisely cut ML35 coils or bars into cylindrical billets of specified weight and dimensions.

- Spheroidising annealing: Heat treat the billets to soften their structure and significantly improve plasticity, preparing them for extrusion.

- Phosphating and saponification: Through acid washing, phosphating, and saponification, form an efficient solid lubricating film on the surface of the billets.

- Cold extrusion forming: Under immense pressure, the lubricated blank undergoes plastic flow within the die cavity to form precise tooth profiles in a single operation.

- Machining: The extruded sleeve blank is turned to produce precise end faces, outer circles, and guide chamfers.

- Quenching and tempering heat treatment: The sleeves undergo quenching followed by high-temperature tempering to achieve a combination of high strength and high toughness.

- Surface treatment: Zinc plating or Dacromet coating is applied for corrosion protection to meet on-site storage requirements.

- Inspection and packaging: Finished products undergo rigorous testing for dimensions, hardness, and torque performance. Qualified products are packaged and stored in the warehouse.

Quality Control and Certification

Each of our products has been certified by authoritative professional bodies, and we promise that all our high-quality services will give you peace of mind.

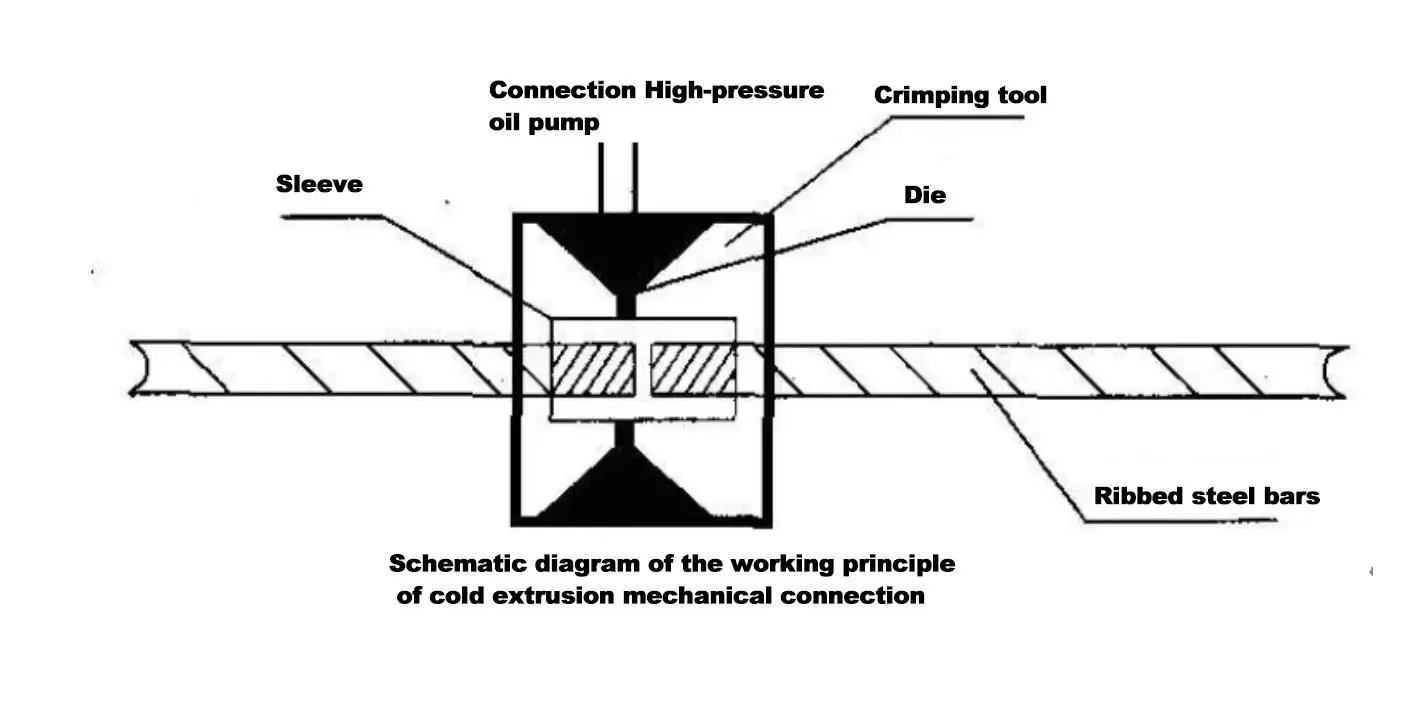

Working principle

The cold extrusion press rebar coupler connection is to squeeze the casing through the cold extrusion machine to connect two reinforcement bars. Meanwhile, the threaded rebar couplers are connected to the two steel bars by tightening the steel bars with the sleeve with two pipe tongs. Cold extrusion connection is to insert the end of the steel bar that needs to be connected into the special steel sleeve, which should be ribbed steel bars. Then the steel sleeves are compressed by a rebar cold extrusion machine to produce plastic deformation, which can realize the connection between the deformation steel sleeve and the mechanical clamping force of ribbed steel reinforcement.

This steel bar connection method is generally used in Ⅱlevel and Ⅲ level rebar with a diameter of 16mm to 40mm, as well as heat treatment steel bars. It can be divided into radial extrusion and axial extrusion.

Installation instructions

1、Marking and Positioning

Apply a red paint mark 100 mm from the end of the steel bar to be connected. Then, apply a check mark at a point 1/2 the length of the sleeve from the end of the steel bar. Ensure that the end of the steel bar aligns with the mark after insertion into the sleeve.

2、Sleeve Installation

Insert the rebar smoothly into the sleeve, ensuring the rebar and sleeve axes align, avoiding eccentricity or voids. The insertion depth should be such that the rebar end is ≤10 mm from the sleeve centre.

3、Cold Extrusion Operation

Start from the centre of the sleeve and squeeze towards both ends in sequence, ensuring the indentations are evenly distributed. Reduce the pressure slightly for the final squeeze.

During squeezing, the crimping tool should be perpendicular to the rebar axis, and the crimping die should move perpendicular to the plane of the rebar’s longitudinal ribs to ensure the indentations are on the transverse ribs.

4、Quality Inspection

- Visual Inspection

Inspect the indentation depth, check for cracks or flared edges in the sleeve, and verify that the outer diameter of the sleeve at the indentation meets the standard. - Sampling Testing

When the inspection criteria are met, commission a qualified testing organisation to conduct on-site random sampling and test indicators such as tensile strength.

Installation Notes

First, compress the sleeve with one end of the reinforcing bar on the ground to form a capped reinforcing bar. At the splicing site, compress the other end. During compression, ensure that the markings on the cut ends of the reinforcing bars align with the centerline of the sleeve;

- Compression should begin from the middle section of the sleeve and proceed sequentially toward both ends. The deviation between the compression marks and the reference points should not exceed 5 mm;

- During compression, keep the rebar straight. Ensure the compression tool remains perpendicular to the rebar’s axis throughout the process to prevent noticeable bending of the joint;

- After positioning the capped rebar, carefully inspect the markings on the rebar ends before splicing and compression to ensure that each rebar is inserted into the centerline of the cold extrusion press rebar coupler;

- The compression force must be adjusted to the specified value, and the reading deviation on the pressure gauge should not exceed 2.0 MPa (Note: The return stroke pressure must not exceed 5 MPa, i.e., it should be less than 5 MPa, or the piston should not return to the bottom).

Cold extrusion press rebar couplers Install core accessories

Rebar Cold Extrusion Press Machine

Rebar Cold Extrusion Press Machine

High-pressure oil pump: Provides a stable output of 60–80 MPa hydraulic power with pressure control accurate to 0.1 MPa, offering a continuous and gentle “source of power” for plastic deformation.

Hydraulic clamp: Forged alloy steel clamp body with multiple heat treatments to ensure 500-ton clamping force; clamp opening and closing takes only 3 seconds, combining efficiency and reliability.

Die: Modular die assembly, with sleeves of the same specification replaceable in 15 seconds; die cavity surfaces treated with DLC coating, extending service life by 3 times.

High-pressure oil hose: Four-layer steel wire braided structure, pressure-resistant up to 100 MPa, with a bending radius of ≤ 80 mm, suitable for narrow tunnel spaces.

Powerful partners

Project case

Fu xia high railway project

ZhangJinggao Yangtze River Bridge

Nanjing Metro Line 7

Product application scenarios