Electric rebar coupler torque wrench

Description

400Nm Electric Rebar coupler Torque Wrench, designed to streamline rebar coupler installation and deliver industry-leading efficiency. Built for demanding construction environments, this wrench features intelligent design and robust components to ensure reliable performance, durability, and ease of use.

Product Features:

- High Torque Output: 400Nm torque capacity for tight, secure connections of rebar couplers.

- Full Electric Drive: Powered by a high-efficiency motor for rapid tightening and loosening—no more manual fatigue.

- Reverse & Forward Control: Switch between forward and reverse directions with simple button operation.

- Speed Control / Variable Trigger: Allows precise control over tightening speed to match different job requirements.

- Durable Gear Teeth: Hardened gear (hardened and tempered) ensures long life, high wear resistance.

- Lithium Battery Powered: Rechargeable lithium battery delivers extended runtime on a single charge.

- Ergonomic Design: Upper handle, balanced weight, ventilation ports for cooling.

- Interchangeable Jaws / Dies: Slot-and-screw-type jaws make it easy to switch dies to fit different sizes of rebars and couplers.

Product Advantages

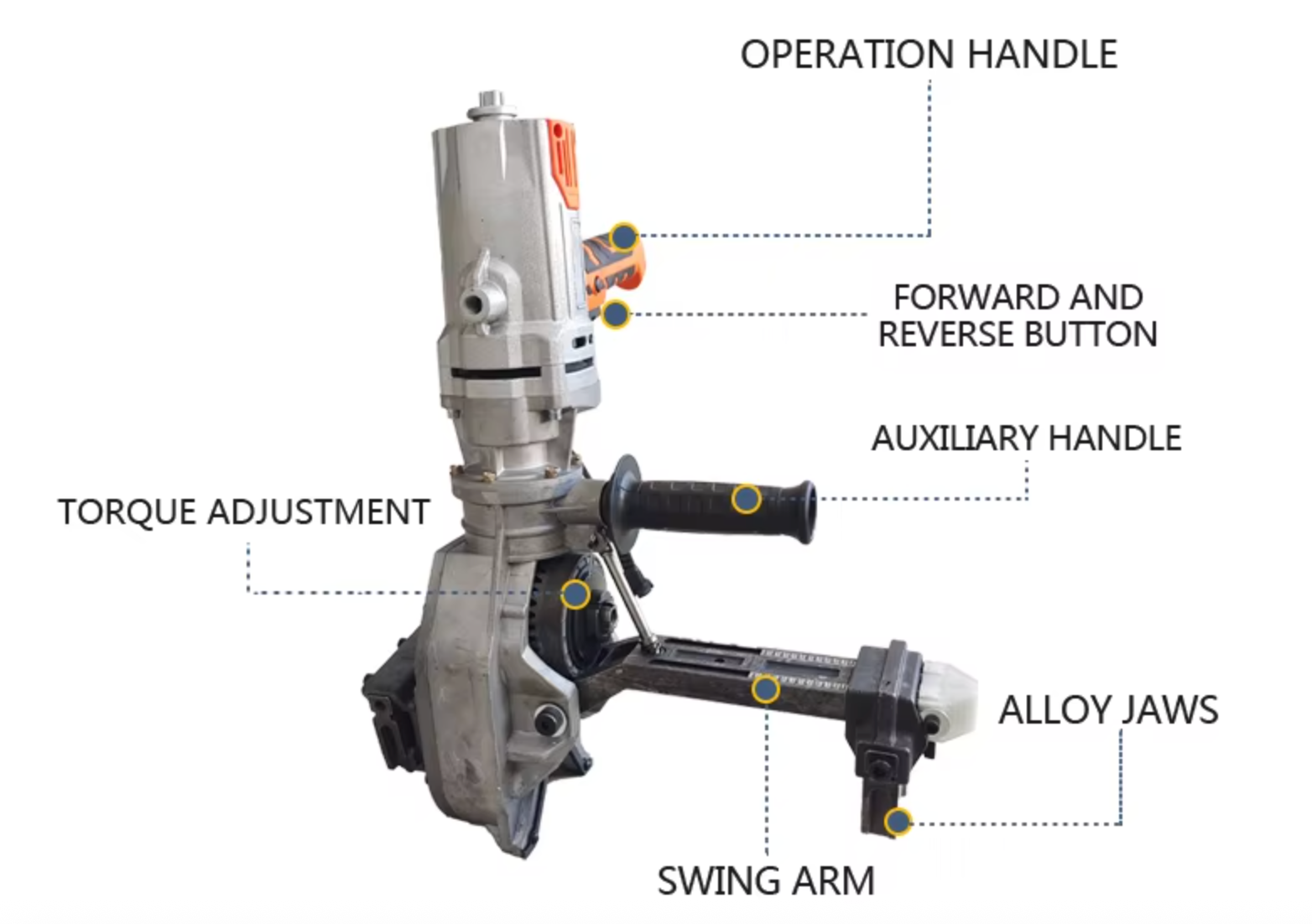

Main Components

- Upper handle

- Forward/reverse button

- Variable speed trigger

- Hardened gear teeth

- Lithium battery

- Battery buckle

- Ventilation ports

Electric rebar coupler torque wrench main Components

Working Principle

Powered by a built-in electric motor, the wrench drives the hardened gear teeth to rotate and engage the coupler, securely connecting rebars with high efficiency.The motor uses a brushless permanent-magnet motor,Its advantages are:

- High Efficiency:Meets the highest international IE4/IE5 efficiency levels; performance is 15 % higher than that of a brushed motor, with even greater gains under heavy load.

- Fast Payback on Energy Savings:Replaces brushed motors and cuts system energy use by up to 30 %, giving longer run-time on the same battery charge.

- Cooler Running:Winding temperature rise is 20 K lower than in a brushed motor, so the machine can run for hours without risk of burn-out.

Multi purpose machine:

1、Electric steel bar coupling torque wrench for transverse installation of steel bars:

Twisted steel bars—compatible with straight-thread rebar from 16 mm to 40 mm diameter.

Screwing the straight threaded rebar coupler-it can clamp an inner diameter of 16–36 mm (outer diameter of the sleeve: 19–53 mm).

2、Electric steel bar coupling torque wrench for vertical installation of steel bars:

Twisted steel bars—compatible with straight-thread rebar from 16 mm to 40 mm diameter.

Screwing the straight threaded rebar coupler-it can clamp an inner diameter of 16–36 mm (outer diameter of the sleeve: 19–53 mm).

Advantages over Traditional Tools:

Significantly higher efficiency vs. manual or pipe wrench methods.

Reduction in labor cost and manual fatigue.

Suitable for heavy-duty construction applications such as bridges, high-rise buildings, tunnels, precast elements.

One-button operation simplifies use and reduces error risk.

Applications

Mechanical connection of rebars using couplers.

Construction projects requiring high-strength reinforcement assembly.

Situations where speed, precision, and durability are essential.

Electric rebar coupler torque wrench opration

What’s Included:

400Nm Electric Rebar Torque Wrench unit

Rechargeable lithium battery pack

Battery charger

Standard interchangeable jaws/dies set

User manual & safety instructions

Quality & Certification:

Manufactured under strict quality controls. Certifications available upon request (e.g. CE, ISO).

Packaging and Logistics