High Strength Thread Rolling Wheel

Exceptional wear resistance and extended service life: one tool outperforms two or even three standard tools;

Superior thread quality and consistency: every thread formed is of premium quality, achieving 100% pass rate in go/no-go gauge inspections;

Outstanding strength and fatigue resistance: specifically engineered for high-strength steel reinforcement, delivering impact resistance and minimal tooth chipping.

Description

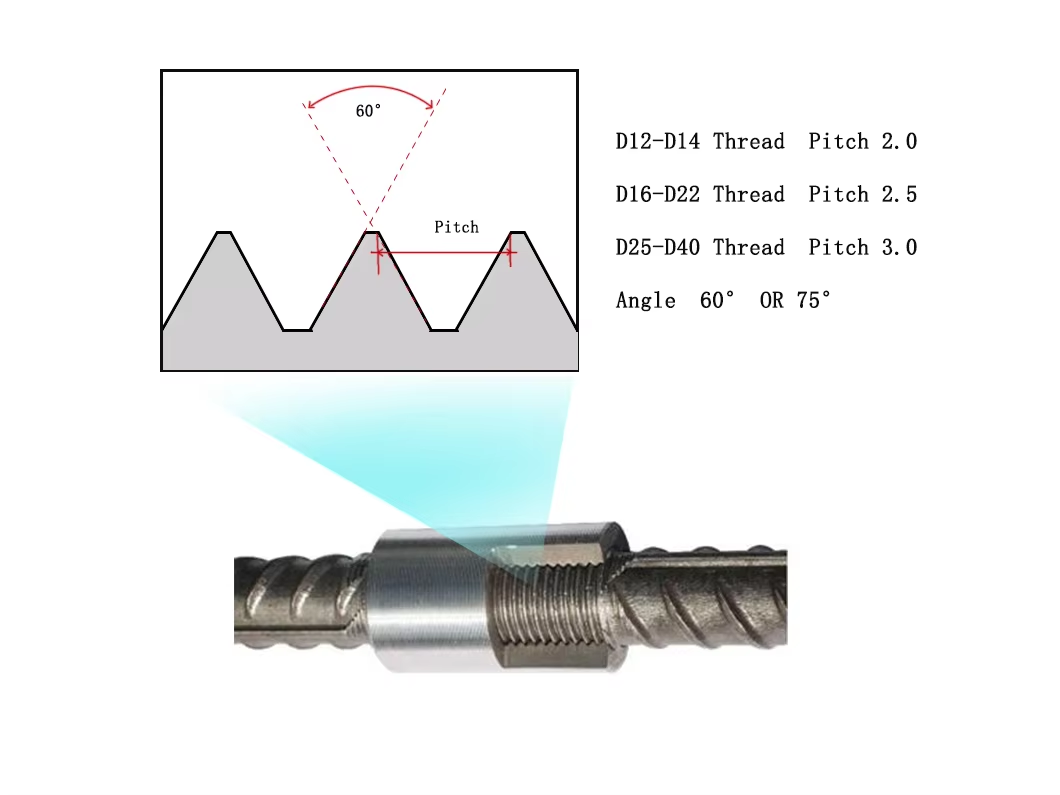

A thread rolling wheel is a tool utilised on a thread rolling machine to form threads by means of plastic deformation of metal.

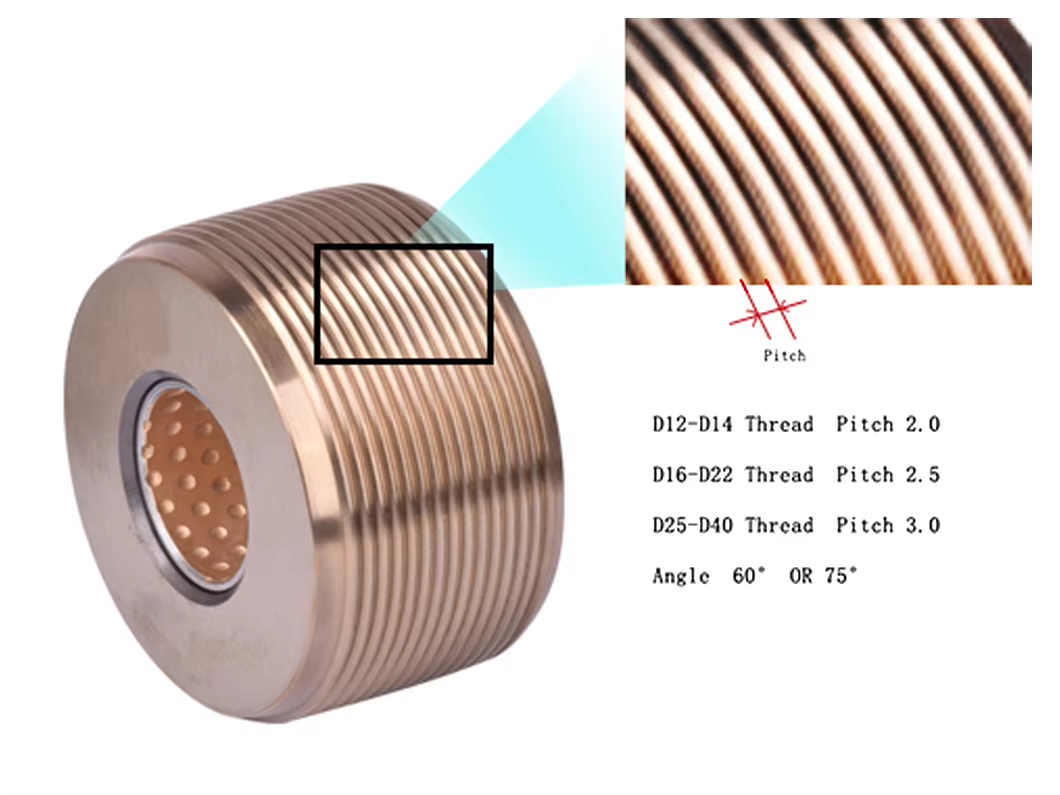

High Strength Thread Rolling Wheel Parameters

| Dia. of Rebar | Φ16- Φ22 | Φ25- Φ32 | Φ36-Φ40 |

| Thread Roller Dia | 78.3 mm | 70 mm | 60 mm |

| Length | 45 mm | 45 mm | 45 mm |

| Inner Diameter | 30 mm | 30 mm | 30 mm |

| Thread Pitch | 2.5 mm | 3 mm | 3 mm |

| Material | Gr12Mov | ||

Product raw materials

High Strength Thread Rolling Wheel are manufactured from Cr12MoV steel. Post-heat treatment specifications require a hardness of 59-62 HRC, deformation ≤0.10mm, and surfaces free from corrosion or decarburisation.

During the thread rolling process, the threaded surfaces of the dies endure repeated alternating compressive stresses and significant impact forces. Coupled with constantly varying loads and high processing speeds, the thread surfaces are prone to fatigue, resulting in tooth breakage and wear. Considering these factors comprehensively, the material requirements for manufacturing thread rolling dies are as follows:

1. High alloy element content to form abundant carbides, enhancing matrix hardness;

2. Superior wear resistance;

3. High compressive strength and toughness;

4. Good hardenability and machinability.

How to Extend the Service Life of Thread Rolling Dies

The thread rolling wheel is a crucial component within the thread rolling machine. To ensure its longevity and thereby extend the machine’s operational lifespan, proper maintenance of the thread rolling wheel is essential.

1. The thread rolling machine exhibits poor precision, excessive vibration, and operates abnormally;

2. Misalignment of the rolling dies causes axial displacement of the workpiece, subjecting the thread profile to both shear and compressive stresses;

3. The rolled thread blanks vary in size, with uncleaned surfaces contaminated by grinding debris, scale, and contaminants;

4. Uneven hardness of rolled parts (Grade 8.8 bolts require 27–30 HRC; Grade 10.9 requires 35–37 HRC). Prevent mixing of un-tempered, high-hardness (50–55 HRC) quenched components with tempered parts due to poor management. Such components possess hardness similar to the thread cutting edges of the rolling dies, causing edge chipping.

5. Failure to apply lubricant during rolling causes dry friction, rapidly elevating tip temperatures beyond the rolling die tempering threshold. This excessive tempering softens the thread profile, resulting in thread collapse or pile-up failure.

6. Rolling dies must undergo thorough demagnetisation prior to dispatch. Residual magnetism attracts fine iron filings during operation, accelerating wear and failure.

7. Insufficient deburring of rebar ribs increases load on the thread rolling wheels. This scenario intensifies wheel wear, causes severe wear on the bronze bushings, and may even cause the wheels to split. Therefore, ensure thorough deburring of rebar ribs to reduce wheel load and prevent rebar ends from bending into an arc shape. This approach significantly extends the service life of the thread rolling wheels.