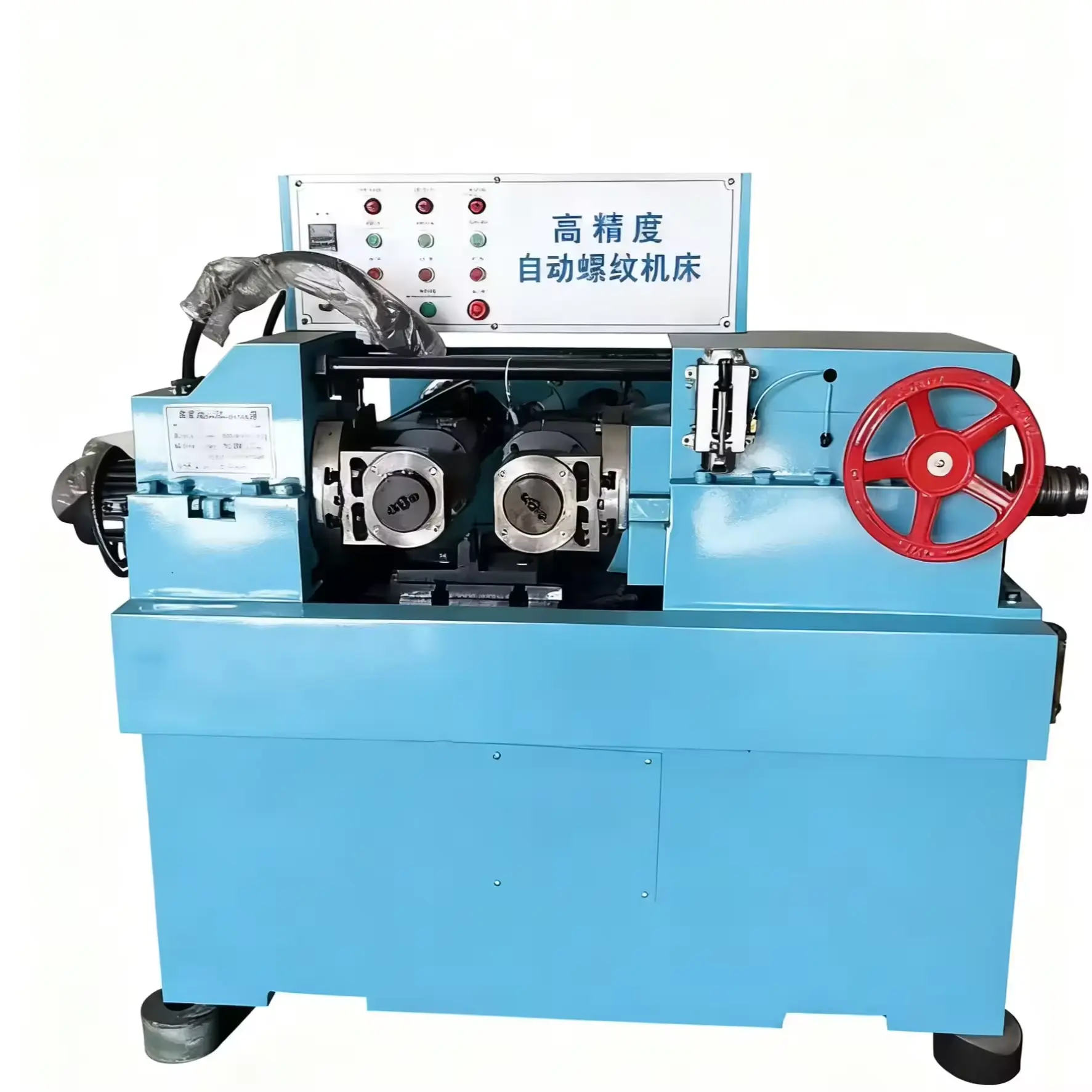

High-Precision Automatic Thread Rolling Machine

Cost reduction and efficiency enhancement: Automated continuous operation, 24-hour uninterrupted production;

Production stability: High equipment precision eliminates quality fluctuations caused by human factors such as mood or fatigue, ensuring high yield rates;

Simplicity of operation: Low skill requirements for operators, short training cycles;

Robust durability: Guaranteed long-term precision retention, extended equipment lifespan, and prolonged investment payback period;

Description

The high-precision automatic thread rolling machine LP-250 is an intelligent cold rolling processing equipment that represents the advanced level of the industry. It is designed for high-volume, high-precision, and high-efficiency thread forming operations. It adopts an advanced electric servo control system and a precise mechanical structure, which has completely revolutionized the traditional thread processing method. This equipment uses a no-waste cold rolling plastic forming process to quickly produce high-quality threads with a smooth surface and higher strength. It can significantly reduce material usage and increase production efficiency, making it an ideal choice for the manufacturing of high-end products such as fasteners and automotive parts.

Automatic Thread Rolling Machine Advantage

high precision

- It uses a high-precision servo motor drive and a closed-loop control system to ensure that the pitch, middle diameter, and other parameters of each rolling are highly consistent and perfectly meet the ISO, DIN, GB, and other international standards and tolerance requirements.

Intelligence and automation

- Fully automatic operation: Integrated automatic feeding, feeding, rolling, and unloading functions to achieve unmanned continuous production and greatly reduce labor costs and operational intensity.

- Human-machine interaction is user-friendly:It is equipped with a large-size touch screen PLC control system. The parameters (such as the lead, speed, and rolling force) are simple and intuitive to set. It can store multiple recipes and easily switch between them.

high quality and high strength

- Work Hardening Effect: The rolling process ensures continuous metal fiber flow lines in the threaded area and increases material density, significantly enhancing surface hardness, fatigue strength, and wear resistance. This extends the service life by over 30% compared to cut threads.

- Excellent Surface Finish: The forming process involves no cutting, resulting in threads free of burrs and cracks with a surface smoothness reaching Ra0.8μm or higher.

High Efficiency, Energy Saving and Environmental Protection

- High-Efficiency Production: Roll-forming operates at extremely high speeds, with processing times measured in seconds per piece, significantly outperforming traditional tapping or turning in terms of output.

- Material Conservation: As a chipless manufacturing method, it utilizes 100% of the blank, eliminating material waste associated with cutting processes.

- Eco-Friendly: Requires no cutting oil, preventing related contamination, and maintains a clean workspace, aligning with modern green manufacturing principles.

Sturdy, Durable and Highly Reliable:

- The machine body is constructed from high-quality cast iron, subjected to precision aging treatment. It offers exceptional vibration resistance and extreme rigidity, ensuring stability during long-term operation.

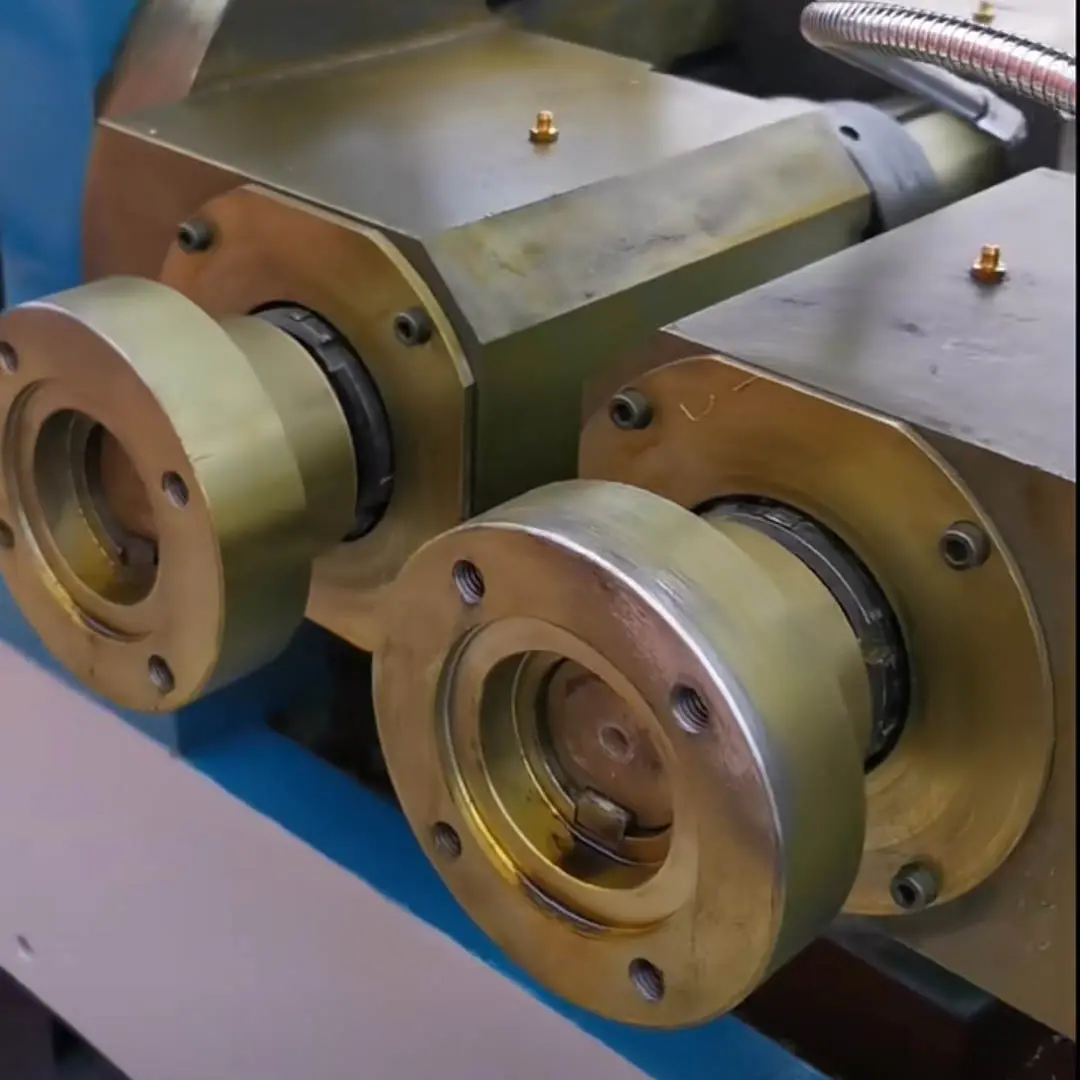

- Key rolling components are manufactured from high-strength alloy steel, undergoing specialized heat treatment and precision grinding for extended durability.

Automatic Thread Rolling Machine Technical Parameters

| Technical parameters | |||

| Maximum rolling pressure | 250KN | Spindle tilt angle | 10 |

| Roll diameter | Φ8-80mm | Spindle speed | 20/26/32/42/52/65(r/m) Optional frequency control |

| Rolling pitch | 1-8mm | Rolling power | 11kw |

| Maximum diameter of thread roller | Φ170-220mm | fluid power | 5.5kw |

| Hole diameter of thread roller | Φ75mm | Cooling power | 0.12kw |

| Maximum width of thread roller | 40-160mm | Weight of the whole machine | 3000kg |

| Spindle Center distance | 160-300mm | Size | 16500*1600*1500mm |

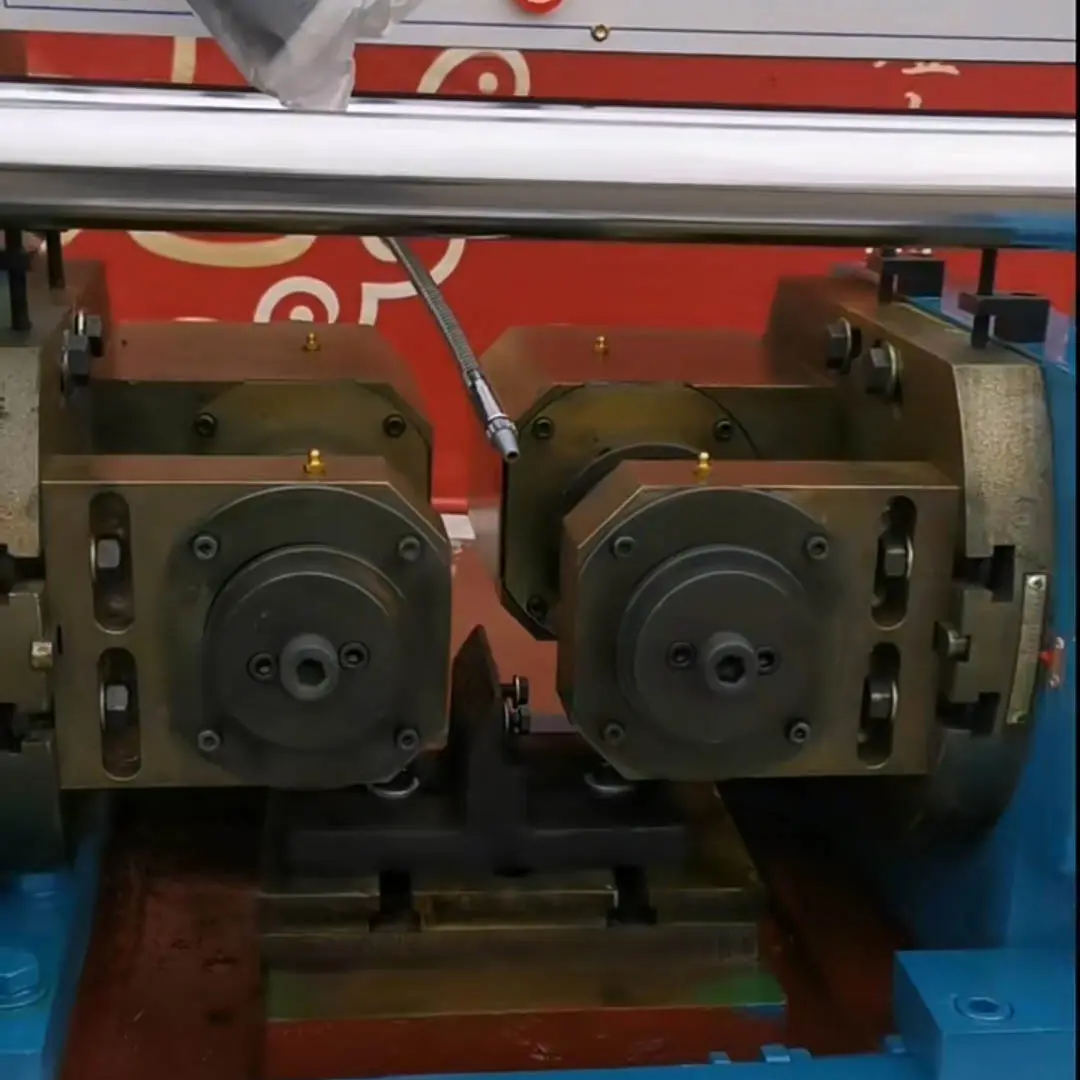

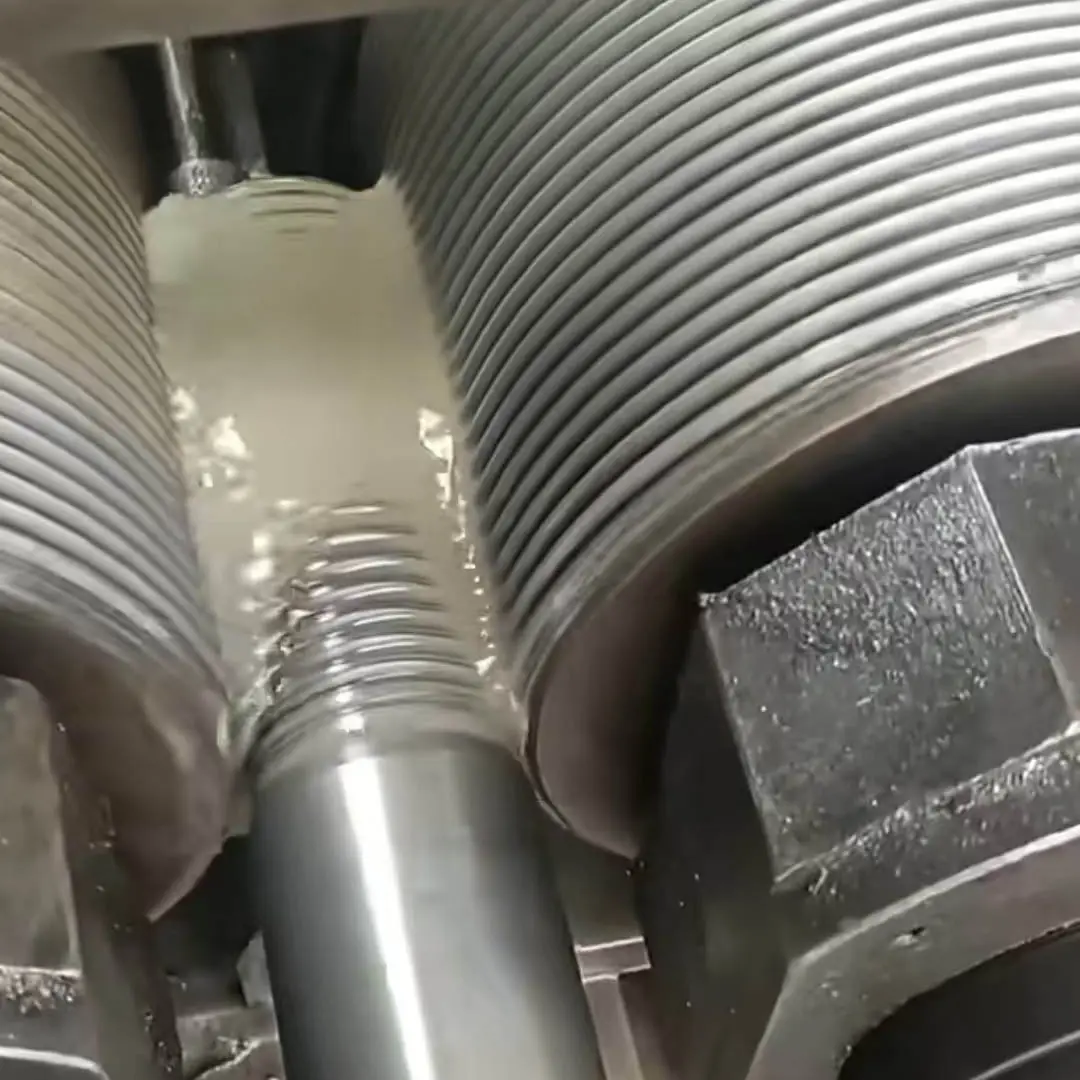

Automatic Thread Rolling Machine Detail

The body is cast as a single unit, ensuring robustness and durability with guaranteed quality!

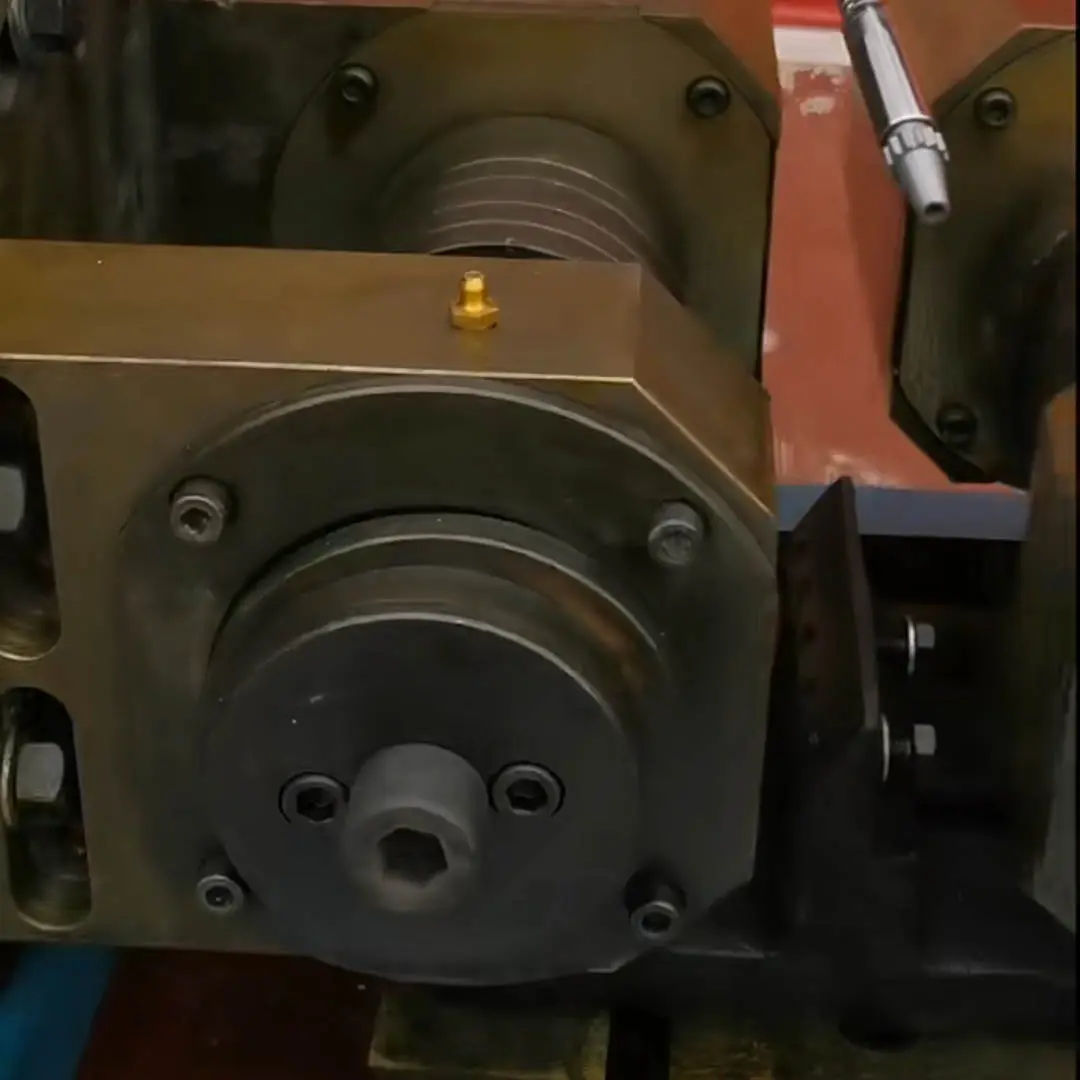

Five ball bearings guarantee precision!

Operating Precautions for Automatic Thread Rolling Machine

Before operation, familiarise yourself with the machine tool manual and strictly adhere to the operating procedures. Should any malfunction or abnormality occur, promptly contact qualified maintenance personnel for resolution.

1、Pre-Operation Preparation and Inspection

Personnel Safety Protection:

- Operators must undergo professional training and pass qualification before commencing duties.

- Wear work attire, safety helmets, and protective eyewear. Gloves, neckties, and loose clothing are strictly prohibited during operation to prevent entanglement with rotating components.

Equipment Condition Inspection:

- Lubrication System:Check oil levels and lubrication status at all points (spindle, thread rolling wheels, feed mechanism, etc.), ensuring unobstructed oil flow. Use specified lubricants/grease as per equipment requirements.

- Pneumatic/Hydraulic System:Verify air supply pressure or hydraulic pressure meets set values. Inspect piping for leaks.

- Fastener Inspection: Verify that all securing screws on critical components—including thread rolling wheels, dies, and feed guide rails—are fully tightened to prevent loosening during operation.

- Die Condition: Inspect thread rolling wheels for cracks, wear, or chipped edges. Strictly prohibit the use of damaged dies.

- Cleaning and Foreign Objects: Clear the workbench and feed rails to ensure no residual iron filings, workpieces, or other foreign objects remain from previous processing.

Programme and Parameter Verification:

- Confirm the machining programme matches the current product to be processed.

- Verify correct settings for process parameters including spindle speed, feed rate, and rolling time.

2、Operational Procedures and Monitoring During Operation

Standard Operating Practices:

- Initial Idle Run: Prior to formal production, conduct an idle run to verify normal movement of all equipment components and detect any abnormal noises.

- First Article Inspection: Following equipment commissioning or product changeover, the first 3-5 units produced must undergo 100% inspection (e.g., go/no-go gauge checks, dimensional measurements). Only upon confirmation of compliance may batch production commence.

- Maintain Focus: Automatic Thread Rolling Machine operators must not leave their posts without authorisation while equipment is running. Closely monitor operational status at all times.

- Handle Anomalies Correctly: Should abnormal noises, vibrations, odours, or sudden changes in product quality occur, immediately press the emergency stop button and notify maintenance personnel for inspection.

Materials and Feeding:

- Inspecting Stock: Ensure bar stock or workpieces meet specified requirements for diameter, hardness, and material composition. Surfaces must be clean, free from oil contamination, and rust-free.

- Standardised Feeding: When using automatic feeders, ensure unobstructed material pathways to prevent workpiece jamming or collisions.

Safety Restricted Areas:

- Prohibited Physical Contact: During operation, it is strictly forbidden to touch rolling workpieces, threading wheels, or moving components with hands or any objects.

- Prohibited Adjustments: Adjusting dies, parameters, or performing cleaning tasks while the equipment is running is strictly prohibited.

3、Shutdown and Routine Maintenance

Standard shutdown procedure:

- First, cease automatic operation mode and return all moving components to their home positions.

- Switch off the main power supply and disconnect the air/hydraulic source.

- Clear iron filings, metal dust and oil residue from the equipment interior to maintain cleanliness.

Routine Maintenance:

- Adhere to the equipment maintenance manual for periodic cleaning, lubrication, and rust prevention of guide rails, lead screws, bearings, and other critical components.

- Regularly inspect and replace worn thread rolling wheels and feed components to ensure sustained machining precision.