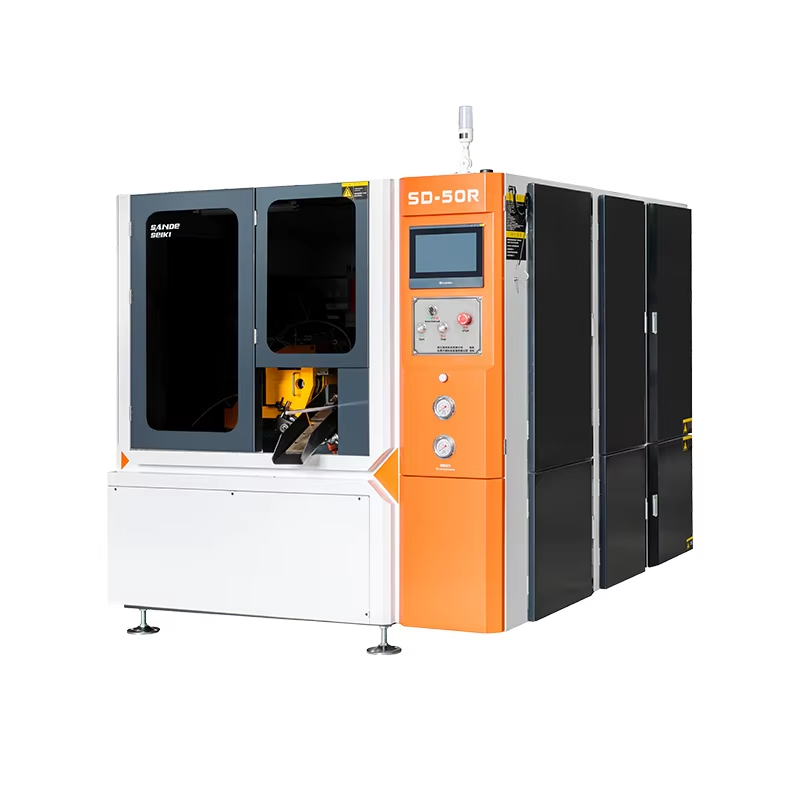

Automatic Steel Pipe Cutting Machine

1.Casting machine body, high rigidity body structure, specially designed for precision cut-off of tube bar;

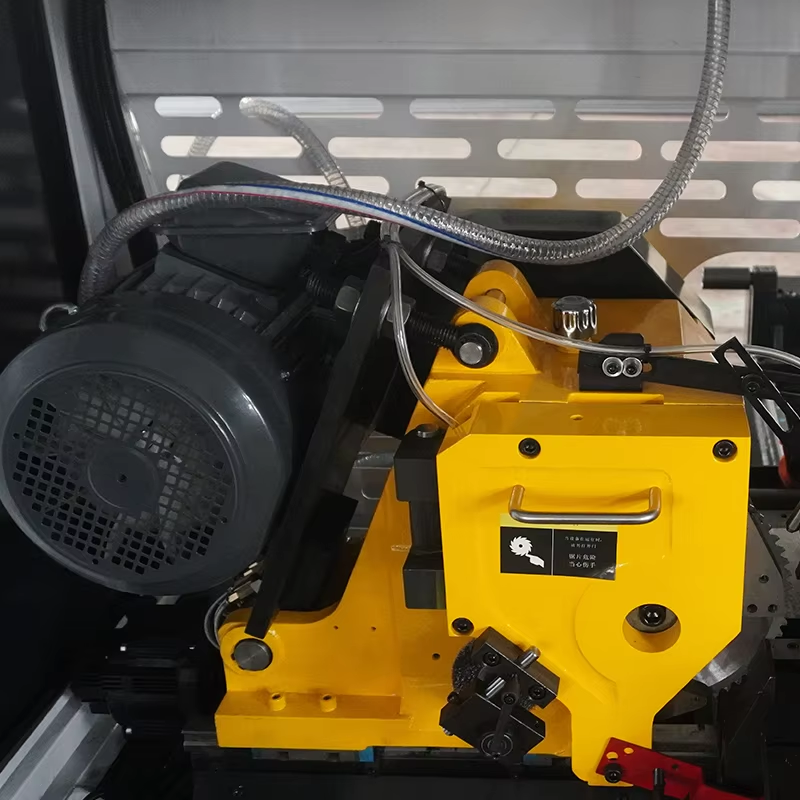

2.Dual-use ofTCT super hard saw blade and HSS high-speed steel saw blade, integration of two machines;

3.The main dlamp adopts three- point clamping of international fashion. Clamping is firm and reliable;

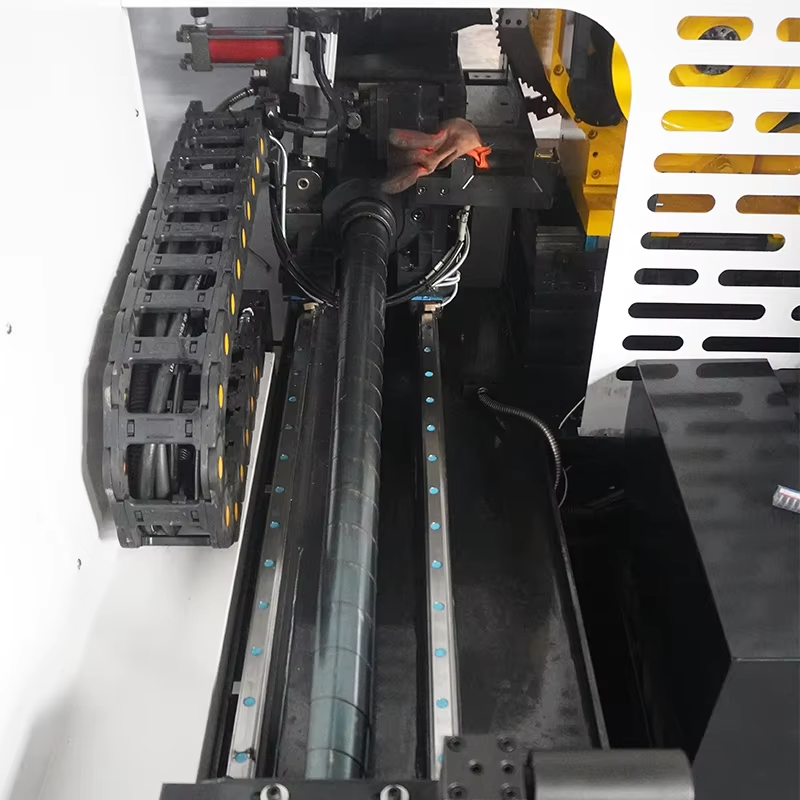

4.With active deflection feeding, material surface damage can be avoided, and feeding precision is improved;

5.With the cooperation of high rigidity, high precision spindle gear box and backlash elimination mechanism,it stabilizes feeding, significantly improves tool life;

6.One-key start, dialogue touch input, simple and quick operation.

Description

The Automatic Steel Pipe Cutting Machine is specially designed for efficient cutting of round pipes, square tubes, and bar materials. Equipped with an AC servo motor and precision ball screw system, it ensures high accuracy and productivity in both feeding and cutting. The machine integrates automatic feeding, hydraulic clamping, chip removal, and micro-lubrication functions for fully automated operation. Ideal for mass production and applications requiring consistent, high-precision cutting, this equipment is the perfect solution to boost your manufacturing efficiency and output.

Automatic Steel Pipe Cutting Machine Specifications

| item | value |

| Applicable Industries | Construction works |

| Weight (KG) | 5700 |

| Showroom Location | None |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2024 |

| Warranty of core components | 1 Year |

| Core Components | Head spindle, Feeding clamp, Automatic feeding device, Hydraulic device |

| Place of Origin | China |

| Warranty | 1 Year |

| Bar range | 30-100mm |

| Angle section range | 30-75mm |

| Round tube range | 30-100mm |

| Square tube range | 30-75mm |

| Use a TCT superhard circular saw blade | D260XT2.6 |

| Pin hole and hole diameter | 4XD12xPCD90XD40mm |

| Spindle motor | 11(4P)KW |

| Spindle speed | 50-120rpm |

| Cut off feed mode | AC servo motor + ball screw / Roller linear guide rail |

| Main clamp way | Hydraulic/each one vertical and horizontal clamps |

Product Features

Innovative Gearbox Design: Features a zero-backlash transmission system that ensures smooth power delivery and extends the saw blade’s service life.

Three-Point Blade Clamping System: Reduces vibration during cutting, improving cutting stability and significantly increasing blade lifespan.

AC Servo Control System: Both cutting and feeding are driven by AC servo motors, ensuring precise feeding, stable cutting, and consistent accuracy.

Fully Automated Operation: Integrates automatic material turning, feeding, scrap separation, and chip removal in one system, reducing labor costs by up to 80%.

User-Friendly Interface: Equipped with a touchscreen control panel for simple operation; easy to use even for general operators without technical training.

Flexible Working Modes: Supports manual, semi-automatic, and fully automatic operation to meet various production requirements.

Product Detail

| Material Type | SD-50R | SD-70R | SD-90R | SD-100R | SD-120R | SD-150R |

| Bar | 10-55 | 15-75 | 20-90 | 30-100 | 35-120 | 45-150 |

| Angle Section | 10-38 | 15-55 | 20-65 | 35-75 | 35-90 | 45-110 |

| Round Tube | 10-55 | 15-75 | 20-90 | 30-100 | 35-120 | 45-150 |

| Square Tube | 10-38 | 15-55 | 20-65 | 30-75 | 35-90 | 45-110 |

Product Video

Application Scenarios

1、Machinery Manufacturing & Steel Structure Fabrication

- Rebar Coupler Production: Used for precise cutting of steel pipes in the manufacturing of rebar couplers.

- Machine Frames: Cutting metal profiles for structural frames and housings of industrial machinery.

- Safety Guards and Protective Covers: Fabricating customized protective structures for machines and equipment.

- Small Steel Structures: Cutting metal supports for racks, workbenches, and display stands.

2、Piping Engineering & Installation

Pipe cutting is essential in both new construction projects and maintenance or replacement work.

- Building Water Supply and Drainage Systems: Cutting stainless steel, galvanized steel, and copper pipes for hot/cold water and drainage installations in buildings.

- HVAC Systems: Cutting steel and copper pipes used for heating, cooling, and ventilation duct components.

- Industrial Piping: Cutting carbon steel and alloy steel pipes for conveying water, gas, oil, or chemicals in chemical plants, power stations, and pharmaceutical factories.

3、Automotive, Motorcycle & Bicycle Manufacturing and Maintenance

- Automotive Exhaust Systems: Cutting and replacing exhaust pipes, mufflers, and related components.

- Vehicle Frames and Chassis Components: Precision cutting of structural tubing during modification or repair.

- Motorcycle and Bicycle Frames: Fabrication and repair of aluminum alloy and steel frames.

Fuel and Air Lines: Cutting brake lines, fuel pipes, and other small-diameter tubes.

4、Sports Equipment & Recreational Facilities

- Fitness Equipment: Cutting metal tubes for various strength and cardio training machines.

- Children’s Playgrounds: Cutting steel frames for slides, swing sets, and playground structures.

- Sports Facilities: Cutting posts and beams for basketball hoops, soccer goals, and similar equipment.

5、Metal Furniture & Office Equipment Manufacturing

This industry requires extremely smooth and precise cutting to ensure aesthetics and easy assembly.

- Stainless Steel Furniture: Cutting tubular frames for tables, chairs, shelves, and display stands.

- Office Chairs and Bases: Precision cutting of aluminum alloy and steel parts such as gas lift rods and bases.

- Fitness Equipment: Cutting metal tubing for treadmills, exercise bikes, and other gym structures.

6、Shipbuilding & Marine Maintenance

- Ship Piping Systems: Cutting complex fuel, lubrication, seawater, and freshwater pipelines on ships.

- Railings and Handrails: Cutting stainless steel or aluminum alloy guardrails and safety rails for marine applications.

Packing & Delivery