Automatic Rebar Bending Machine

Description

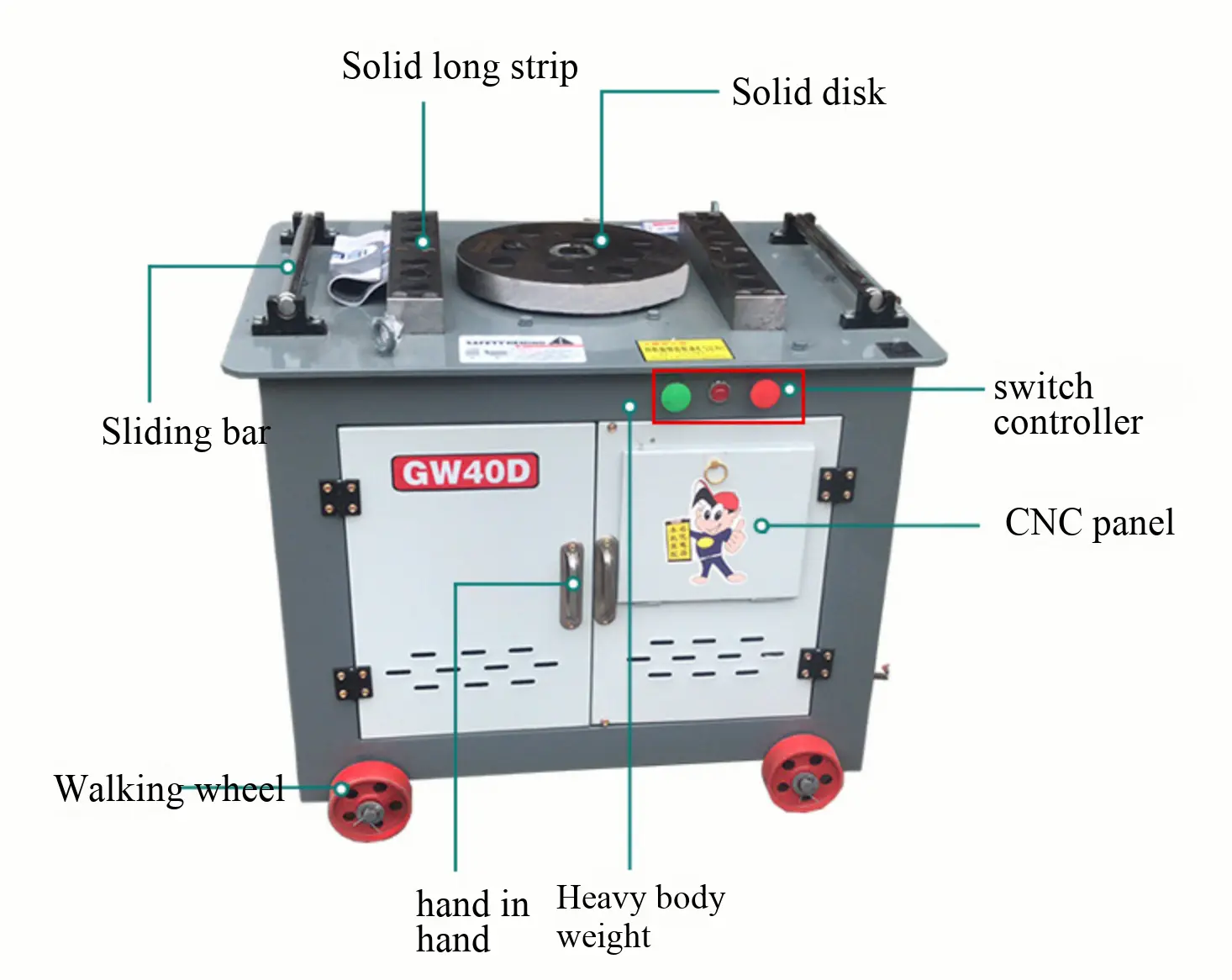

Automatic Rebar Bending Machine, specifically engineered for Φ6-45mm reinforcing bars. Featuring a robust cast-iron frame, it delivers powerful performance with precise and efficient bending capabilities. Its user-friendly operation ensures safety and reliability, significantly enhancing construction efficiency and quality. This machine serves as the ideal reinforcing bar processing equipment for construction sites and precast component factories alike.

Dear customer, we offer various Rebar Bending Machine models and sizes that may not all be listed here.

If you need a customized rebar coupler or machine and Rebar Processing Machine, please contact us with your requirements.

Samples or technical drawings can be provided for non-standard customization.

Rebar Bending Machine key attributes

| material / metal processed | Aluminium Alloy, Aluminum, Brass / Copper, Stainless Steel, Carbon Steel |

| core components | Bearing, Gearbox, Motor, Pressure vessel, Gear |

| automation | Automatic |

| warranty | 3 Years |

| key selling points | Competitive Price |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| motor power (kW) | 5.5 |

| weight (kg) | 580 |

| place of origin | China |

| brand name | Anda Machinery |

| Product name | GW50 Automatic Rebar Bending Machine |

| Power | 4 kW–7.5 kW |

| Voltage | 220 V / 380 V / 415 V / 440 V / customized |

| Bending Diameter | 6–45 mm Rod Bar |

| Bending material | Carbon steel, stainless steel, copper, aluminum |

| Packaging | Iron frame protection |

| Packing size | 1200 × 980 × 750 mm |

| Gross weight | 590 kg |

| Color and LOGO | Can be customized |

| Applicable scenario | Building construction |

Product Advantages

- Simple structure: The Rebar Bending Machine features a compact design for ease of operation and portability.

- Reliable performance: The robust machine construction ensures dependable operation during extended use.

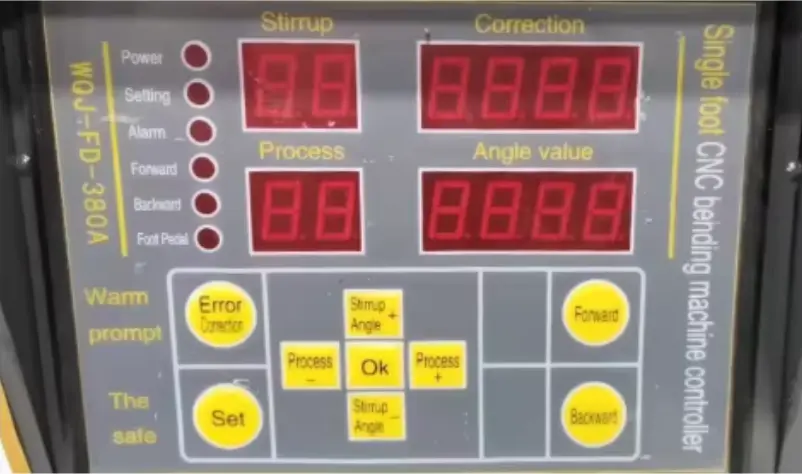

- Responsive operation: Utilising an advanced control system, it delivers swift and precise operational responses.

- Versatile application: Accommodates a wide range of bending diameters and angles to meet diverse project requirements.

- Rapid bending speed: Completes bending operations in approximately 3 seconds, offering powerful drive and high work efficiency.

Prodouct Detail

The disc is made of fine steel,It does not deform whenbending large-diameter reinforcement,lt is firm and durable, and is deeply loved by end users.

Simple operation,intelligent operation,automatic completion ofsize setting, accurate accuracy.

Pure copper coil made ofexcellent red copper has highquality heat dissipationfunction, and the end customerfeedback will not burn themotor even if the generatorvoltage is unstable.

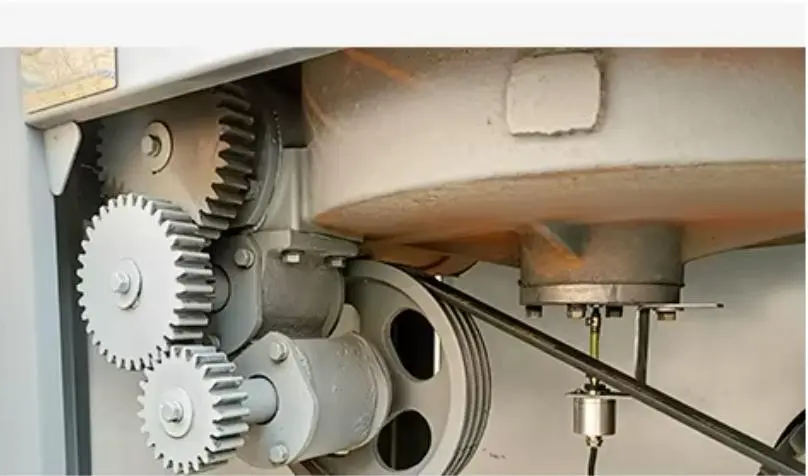

Robust gear transmission, ample power, simple construction for easy maintenance.

User-friendly design for convenient operation, saving time and labour. The foot switch for the bending machine is crafted from stainless steel, offering high hardness, excellent toughness and extended service life.

Safety Operating Procedures for Rebar Bending Machine

- The workbench and the bending machine’s worktop shall be maintained level.

- Prior to operation, all mandrels and tools shall be prepared. Mandrels, forming shafts, and stop pins of appropriate specifications shall be fitted according to the diameter of the reinforcing bar and the required bending radius.

- Mandrel diameter shall be 2.5 times the rebar diameter. Stop pins must be fitted with bushings. Stop pin diameter and strength shall not be less than those of the rebar being bent. Do not bend warped rebar on the machine.

- Prior to start-up, inspect and confirm that mandrels, stop pins, turntable, etc., are free from cracks or damage. Ensure guards are securely fastened and operate reliably. Conduct a no-load test run.

- During operation, insert the end of the bar to be bent into the gap between the turntable’s fixed pins, with the other end pressed firmly against the machine body’s fixed pin for clamping. Only start the machine after verifying the machine body’s fixed pin is positioned to block the bar.

- During operation, it is strictly prohibited to replace the mandrel, forming shaft, pins, alter angles, or adjust speeds. Lubrication or cleaning must not be performed whilst the machine is running.

- It is strictly forbidden to bend reinforcing bars exceeding the machine’s specified diameter or quantity limits.

- When bending high-strength or low-alloy steel bars, convert the maximum permissible diameter according to the machine’s nameplate specifications. Where necessary, replace the bending machine’s corresponding mandrel.

Processing results of the rebar bending machine