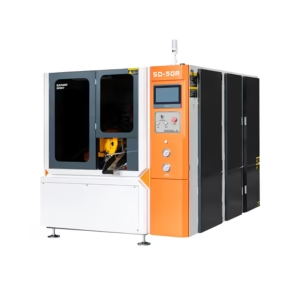

Automatic Chamfering Machine for Metal Pipes and Rebars

High efficiency: Capable of machining two edges simultaneously, significantly enhancing production efficiency.

Flexibility: Adjustable cutting angles and depths ensure strong adaptability.

Precision: Utilises high-precision cutting tools and control systems to guarantee machining accuracy.

User-friendly operation: Rational design and straightforward operation reduce operational complexity.

Description

The Automatic Chamfering Machine is designed for efficient chamfering and end-face processing of metal pipes and bars. Equipped with a CNC control system and alloy blade cutting, it ensures precise, smooth, rebar couplers,and consistent chamfering for materials such as stainless steel and carbon steel.

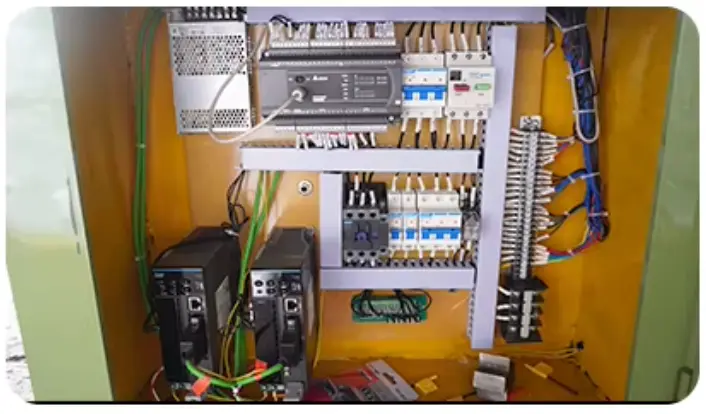

Core components include high-quality bearings, a reliable motor, PLC control, and a durable gearbox, providing stable operation and long service life.

With a 1-year warranty and complete machinery test report, the machine supports processing diameters from 20mm to 80mm and cutting lengths from 30mm to 90mm.

Product Parameter

| Model | Range of values |

| Processing Diameter | 20–80 mm |

| Processing Length | 30–90 mm |

| Working Accuracy | ±0.05 mm |

| Working Speed | 2–3 s/pcs |

| Motor Power | 4.0 kW |

| Oil Pump Pressure | 2.2–4.0 MPa |

| Machine Size | 100 × 105 × 180 cm |

| Machine Weight | 700 kg |

Product Features

- Low fuel consumption with High Productivity.

- Easy to operate and easy to use.

- The diameter can be modify according to customer requirements.Good mechanical parts ensure machine runs in high stability.*Chamfering knife forward,backward and chamfering working all driven byhydraulic.

- Material Available: Carbon Steel,Stainless Steel,Copper,Aluminum…

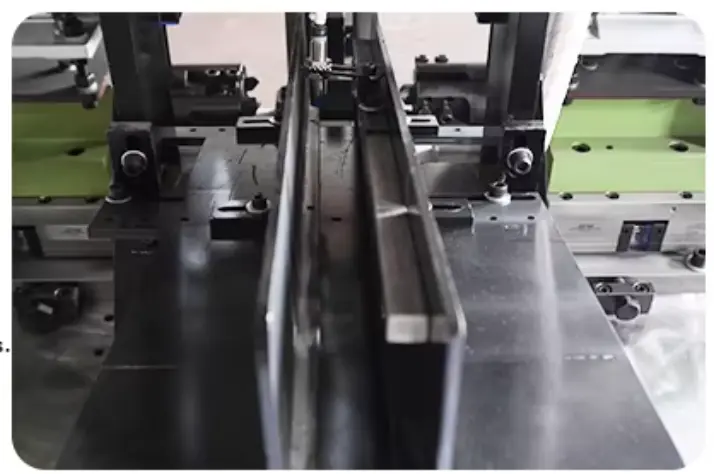

Automatic Chamfering Machine Detail

The operating interface employs a side-by-side layout with clearly defined functional indicators, ensuring straightforward operation. The panel supports customisation for different national languages.

Replace different sizes of pipe fittings, justreplace the fixture, adjust the cutter head,complete equipment specifications for you tochoose, to meet the needs of different industries.

Automatic feeding, labor saving, automaticproduction.

The use of brand electronic control equipmentstable performance.

Product processing effect

Product Operational Precautions

- Strictly adhere to operating procedures: When operating the chamfering machine, ensure compliance with the equipment’s operating guidelines. Avoid unauthorised modifications to settings or parameters to prevent accidents.

- Prioritise personal protection: When operating the equipment, wear personal protective equipment such as safety goggles to prevent injury from metal shavings.

- Regular equipment maintenance: To ensure proper functioning and extend the equipment’s service life, perform routine maintenance. This includes regularly replacing lubricants and clearing metal shavings generated during grinding.

- Avoid overloading: During operation, adhere to the equipment’s rated capacity and prevent overloading to avoid damaging the machinery or compromising processing quality.

- Maintain environmental safety: Keep the working environment tidy and secure during equipment use. Promptly clear oil spills, metal shavings, and other debris from the floor to prevent slips or other safety incidents.

- Adherence to shutdown and start-up procedures: When shutting down or starting the equipment, strictly follow the correct procedures to prevent damage to the equipment or personal injury due to improper operation.

- Key safety points for chamfering machine operation: It is strictly forbidden to remove protective covers without authorisation when using the chamfering machine. Female employees must tie back their hair to prevent it from being caught in the belt.