Rebar coupler for bridges – Zhang Jinggao Yangtze River Bridge Project

As another milestone in China’s bridge construction history, the Zhangjinggao Yangtze River Bridge has stunned the global infrastructure sector with its six “world’s largest” engineering features. Behind this super project, mechanical rebar connection systems and advanced rebar coupler for bridges played a crucial role. Hengshui Anda Machinery Equipment Co., Ltd. was honored to serve as one of the project’s rebar coupler suppliers. This comprehensive analysis explores the innovative application and practical experience of mechanical rebar connection technology in this world-class bridge project, examining multiple dimensions including project overview, technical principles, specific application cases, smart construction integration, quality control systems, and technical-economic analysis.

Zhang Jinggao Yangtze River Bridge Project Background

The Zhangjinggao Yangtze River Bridge is a major transportation infrastructure project spanning the cities of Zhangjiagang, Jingjiang, and Rugao in Jiangsu Province. With a total route length of approximately 30 kilometers, it is located about 28 kilometers downstream from the Jiangyin Yangtze River Bridge and approximately 16 kilometers upstream from the Shanghai-Suzhou-Nantong Bridge. It is a key implementation project for river crossings explicitly designated in Jiangsu Province’s comprehensive multi-modal transportation corridor plan for the Yangtze River Economic Belt.

As the world’s largest suspension bridge currently under construction, it has achieved six world records: the world’s longest suspension bridge span, tallest suspension bridge towers, longest high-strength main cables, largest composite diaphragm wall anchor foundation, longest continuous steel box girder, and largest displacement expansion joint. This super-engineering project stands not only as a flagship model for Jiangsu’s contribution to China’s transportation powerhouse initiative, but also as a landmark achievement in China’s bridge technology innovation and a milestone in global mega-span suspension bridge construction.

What challenges did the Zhangjinggao Yangtze River Bridge project face?

In such a monumental and complex project, the quality of rebar connections—as the skeletal framework of concrete structures—directly impacts the overall safety and durability of the structure. The rebar engineering for the Zhangjinggao Yangtze River Bridge faced unprecedented technical challenges:

- Massive structural dimensions: The southern anchorage foundation of the South Channel Bridge measures 110.05 meters in length and 75.05 meters in width, with walls reaching 83 meters deep. Excavation depth for the foundation is 52 meters, requiring 550,000 cubic meters of concrete and steel equivalent to over eight Eiffel Towers. Such an enormous reinforced concrete structure imposes extremely high demands on the reliability of rebar connections.

- Dynamic load environment: As a 2,300-meter-span ultra-long suspension bridge, the structure will undergo significant deformation under wind loads, vehicular traffic, and temperature fluctuations. This necessitates reinforcement connections with excellent fatigue resistance and deformation-following capability.

- Complex construction conditions: With the main towers soaring 350 meters high, traditional welding methods prove inefficient and unreliable for high-altitude operations like upper girder closure, posing significant safety risks.

- Extremely high precision requirements: For instance, during the “cloud-level closure” of the upper crossbeam on the south tower, millimeter-level positioning accuracy is required for hundred-ton steel structures. This demands exceptionally high dimensional precision and construction controllability for the embedded steel reinforcement and connection nodes.

- Strict durability requirements: With a design lifespan exceeding 100 years and exposure to the humid, saline, and corrosive environment of the Yangtze River estuary, the corrosion resistance and long-term stability of the steel reinforcement joints are critical.

Facing these challenges, the Zhangjinggao Yangtze River Bridge project team significantly reduced the use of traditional rebar tying and welding techniques, shifting instead to the large-scale adoption of advanced mechanical connection technologies—particularly the straight-threaded sleeve connection method. By integrating high-performance rebar coupler for bridges solutions into the construction process and combining technological innovation with smart construction, the team successfully resolved the complexities of rebar connection in this super-large bridge project, setting a new technical benchmark for similar engineering endeavors.

What is Reinforcing Bar Mechanical Connection Technology?

Rebar mechanical splicing technology, a revolutionary alternative to traditional tying and welding methods, has evolved into a mature system since its development in the late 20th century. This technology transfers force between bars through mechanical interlocking or compression at the bar ends, earning it recognition as the “third-generation” rebar connection method after tying and welding. In the landmark Zhangjinggao Yangtze River Bridge project, the innovative use of rebar couplers designed for bridge applications fully demonstrates the technical advantages of this system in mega-scale infrastructure construction.

The primary types of mechanical connections for reinforcing bars can be categorized into three major classes: sleeve compression connections, tapered thread connections, and straight thread connections. Following comprehensive technical and economic comparisons, the Zhangjinggao Yangtze River Bridge project primarily adopted the peeled-rib rolled straight-thread sleeve connection technology. This method employs specialized rolling equipment and processes to directly roll straight threads onto rebar ends using threading wheels, then securely connects two bars using corresponding coupling sleeves. Compared to other connection methods, straight-thread connections offer the following significant advantages:

- High strength and stable performance: The threading process does not weaken the cross-section of the rebar, ensuring the joint strength is no less than that of the parent material. This meets the stringent structural safety requirements of bridge engineering.

- High adaptability: Capable of connecting both same-diameter and different-diameter rebars, it is suitable for joining rebars of various grades such as HRB400 and HRB500. This provides significant convenience for arranging rebars in complex nodes of bridges.

- High Construction Efficiency: Simple on-site connection operations allow each joint to be completed in just minutes, significantly accelerating construction progress. This is particularly suitable for dense reinforcement nodes in bridge projects.

- Environmentally Friendly and Energy Efficient: No open flame operations are required, making it unaffected by weather conditions. Energy consumption is only one-tenth that of welding, aligning with green construction principles.

How did the team improve the rebar connection technique?

In the specific application of the Zhangjinggao Yangtze River Bridge, the project team implemented multiple innovative improvements to traditional mechanical connection technology:

- Precision Control Upgrade: To meet the bridge’s ultra-high precision requirements, a specialized high-precision thread machining process was developed, controlling thread tolerances within ±0.1mm to ensure every connection joint achieves “millimeter-level compliance” standards.

- Corrosion Protection: To withstand the high humidity and salt fog environment at the Yangtze River estuary, the interior of the sleeves was filled with a special sealant, while the exterior received multiple layers of anti-corrosion coating, significantly enhancing the durability of the joints.

- Standardized Construction Process: A standardized workflow was established covering steel bar cutting, end processing, thread machining, and on-site connection. The entire process underwent quality control through an intelligent production center.

Compared to traditional connection methods, the application of rebar coupler for bridges technology in the Zhangjinggao Yangtze River Bridge demonstrates significant technical and economic advantages.

From a technical performance perspective, using rebar couplers eliminates heat-affected zones and does not alter the metal microstructure, ensuring the mechanical properties of the joint match those of the base material.

Regarding quality control, the quality of connections made with rebar couplers remains consistent regardless of operator skill, offering high stability.

From a construction and scheduling standpoint, the use of rebar couplers enables prefabrication, which reduces on-site work time and minimizes risks associated with high-altitude operations.

What are some innovative application cases in key areas?

The Zhangjinggao Yangtze River Bridge, a super-engineering feat boasting multiple “world’s largest” titles, demands diverse and high-standard applications of mechanical rebar connection technology across its various structural components. Tailoring solutions to the structural characteristics and load requirements of each critical section, the project team demonstrated the adaptability and reliability of this technology through multiple innovative application cases.

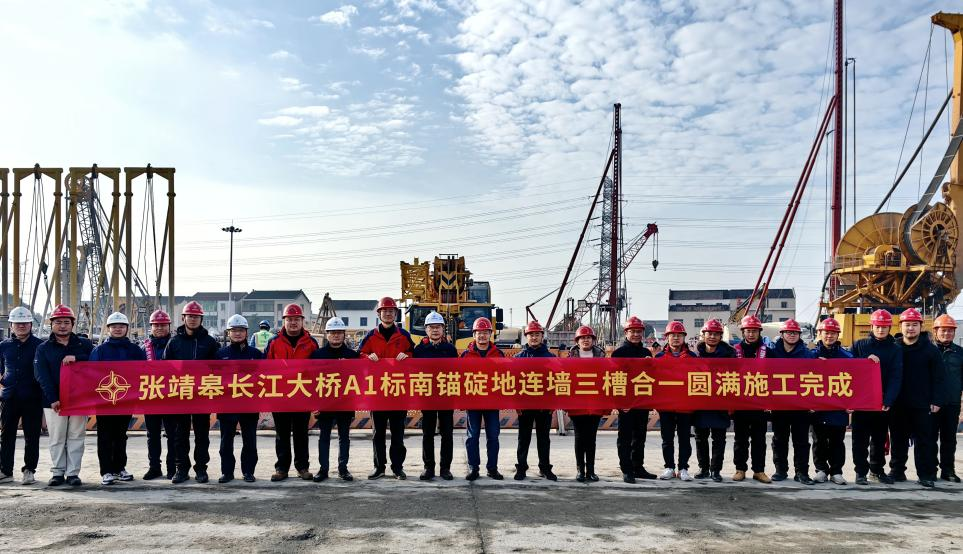

1. Construction of the diaphragm wall for the south anchorage foundation of the South Channel Bridge

The southern anchorage foundation of the South Channel Bridge is one of the most critical load-bearing structures of the Zhangjinggao Yangtze River Bridge, with its diaphragm wall construction serving as the project’s cornerstone. Measuring 110.05 meters in length and 75.05 meters in width with a wall depth of 83 meters, this foundation features a honeycomb-like compartmentalized structure formed by connecting 162 segmental sections. Divided into 32 small compartments and 15 large compartments, it required pouring 550,000 cubic meters of concrete and used more steel than eight Eiffel Towers. In such an exceptionally large-scale diaphragm wall construction, ensuring the precision of segmented connections and the integrity of the reinforcement cages presented significant technical challenges.

The project team innovatively adopted a composite technical solution combining “rigid socket joints with mechanical connections,” successfully resolving this challenge. During implementation, the massive steel cage was first divided into several standard segments for industrial prefabrication at the intelligent steel production center. Each prefabricated segment featured pre-installed high-precision straight thread sleeve connectors at the rebar ends. During on-site hoisting, specialized guiding and positioning devices ensured precise alignment between segments. Corresponding threaded sleeves were then tightened to connect the segments, followed by high-performance concrete pouring in the joint areas.

The advantages of this technical solution are demonstrated in multiple aspects:

- Construction Accuracy Control: Utilizing digital twin technology, we independently developed a dual-wheel milling auxiliary decision-making system. Through an “intelligent brain,” it implements comprehensive control over all elements of the trenching process. We iteratively upgraded the contact-type trenching detector, which monitors trench wall morphology via mechanical contact. This enables frequent measurement and timely correction, ensuring construction accuracy for ultra-deep and ultra-long diaphragm wall sections.

- Connection Reliability: Mechanical joints maintain stable performance unaffected by adverse conditions like moisture and temperature fluctuations in ultra-deep underground environments, safeguarding the integrity of the diaphragm wall.

- Construction Efficiency: Compared to traditional welding methods, mechanical connections reduce joint installation time from 30 minutes to under 5 minutes, significantly boosting construction efficiency.

2. Application of Prestressed Grids in Main Cable Anchoring Systems

| Application Area | Connection Type | Rebar Specification | Quantity | Special Requirements | Technical Innovation |

| South Anchorage Diaphragm Wall | Straight Thread Coupler | HRB400, ø32-40 mm | ~560,000 | Ultra-deep underground corrosion resistance | Rigid plug-in composite connection |

| South Main Tower Upper Crossbeam | High-Strength Threaded Joint | HRB500, ø28-36 mm | ~120,000 | High-altitude rapid alignment | Hydraulic-assisted positioning system |

| Main Cable Anchorage System | Prestressing Specialty Coupler | Alloy Steel, ø50 mm | ~32,000 | High fatigue resistance | Optimized thread fatigue performance |

Comparison of Application Parameters for Mechanical Connection Technology of Key Structural Steel Members in the Zhangjinggao Yangtze River Bridge

These innovative application cases in critical structural areas fully demonstrate the adaptability and reliability of mechanical rebar connection technology in super-large bridge engineering. Tailoring solutions to the structural characteristics and construction conditions of different locations, the project team developed differentiated connection approaches. This not only overcame the limitations of traditional techniques but also expanded the performance boundaries of modern rebar engineering, accumulating invaluable experience for bridge construction in China and worldwide.

3. The crossbeam on the south main tower is joined

On December 1, 2025, the southern main tower of the South Channel Bridge of the Zhangjinggao Yangtze River Bridge successfully completed its “cloud-end closure” with the final beam installation, marking the full capping of this 350-meter-tall “steel giant.” Behind this milestone achievement, mechanical rebar connection technology played an irreplaceable role in ensuring precision assembly at great heights.

The upper crossbeam, serving as the “aerial load-bearing hub” of the suspension bridge’s main tower, endures immense bending and shear stresses. Its intricate internal steel reinforcement network poses challenges for traditional connection methods to meet the demands of rapid high-altitude assembly. The project team adopted a fully prefabricated assembly process, dividing the upper crossbeam into multiple steel-concrete composite modules. After factory prefabrication, these modules were lifted to a height of 350 meters for on-site assembly. Throughout this process, all steel connections between prefabricated components utilized specially designed straight-thread sleeves. The world’s first 10,000-ton-meter tower crane precisely positioned the 262-ton steel box into its designated location, achieving “millimeter-level precision in handling a hundred-ton steel structure.”

How Zhang Jinggao Yangtze River Bridge Achieved Quality Control in Reinforcing Bar Connections

The quality of mechanically connected steel bars directly impacts the safety and durability of the entire structure. The Zhangjinggao Yangtze River Bridge project established a comprehensive quality control system covering all stages—from materials and fabrication to construction and acceptance—ensuring the reliability of hundreds of thousands of mechanically connected joints.

- In material control, the bridge strictly implements the “three certificates in one” system for reinforcing bars and connecting sleeves, requiring complete matching of product certificates, quality assurance documents, and third-party inspection reports.

All incoming materials must pass through the smart production center’s QR code scanning system for automatic verification and traceability record retention. For critical components like straight thread sleeves, the project imposes triple inspection standards for hardness, thread precision, and corrosion resistance. Non-compliant items are automatically segregated and marked. - Process quality control relies primarily on the automated inspection system at the Smart Production Center. During thread rolling, built-in laser gauges continuously monitor key parameters like thread mean diameter, pitch, and thread angle. Any deviation triggers immediate alerts and halts production.

- Each processed rebar end is fitted with a plastic protective cap to prevent thread damage during transportation. This meticulous management measure significantly enhances the pass rate for subsequent on-site connections.

- Through rebar threading and straight thread sleeve connection skill competitions, frontline workers’ awareness of standardized operations and technical proficiency have been effectively strengthened, providing robust support for comprehensively improving the quality of physical engineering structures.

Hengshui Anda Machinery Equipment Co., Ltd. is honored to participate in this bridge project. This project effectively validates the quality and technology of our bridge rebar couplers. It further demonstrates the reliability of our products and technical services.

The adoption of bridge rebar couplers in major projects like the Zhangjinggao Yangtze River Bridge ensures construction quality and schedule. It also reduces long-term maintenance costs. This reflects advanced process technology. The couplers’ reliability and eco-friendly characteristics align with national requirements for high-quality, sustainable infrastructure. They play a positive role in driving innovation for bridge engineering technology.