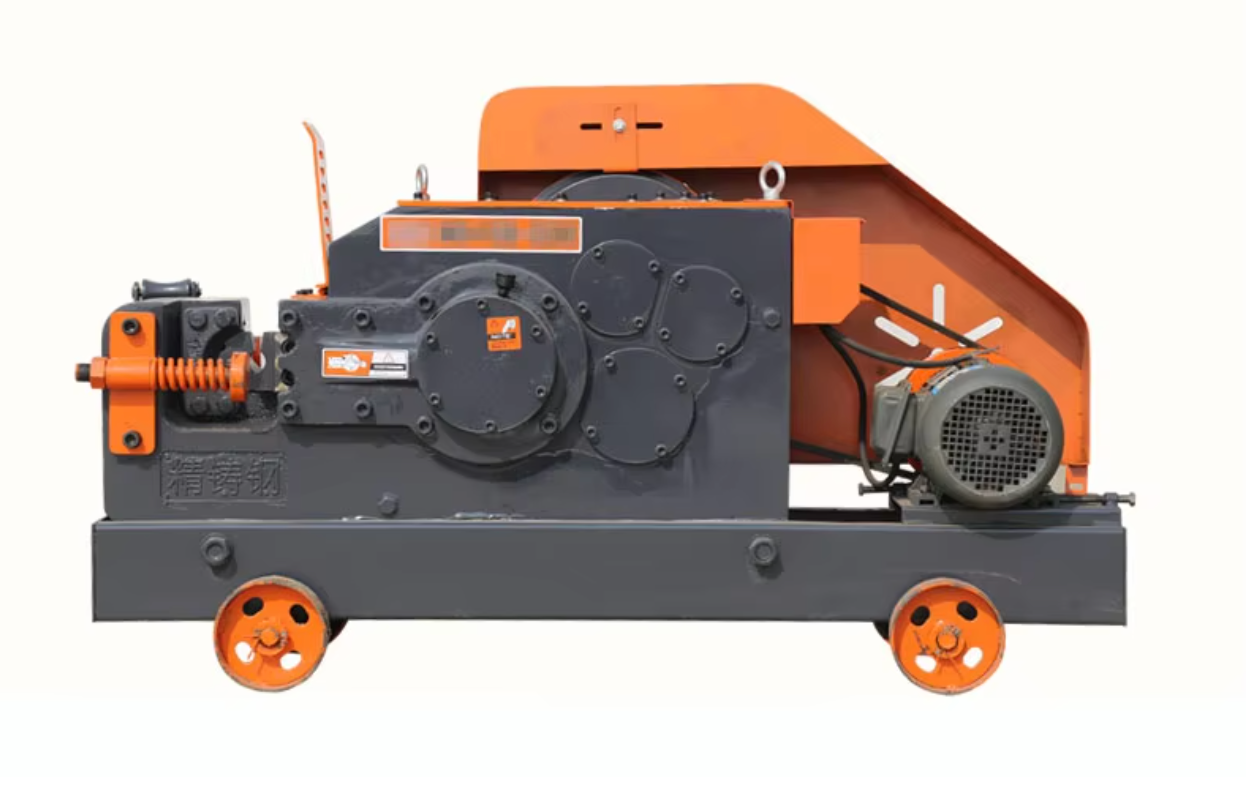

Steel bar cutting machine

- Competitive factory price

- Direct manufacturer sale

- Fast & clean cutting performance

- Long service life

- For construction & rebar processing plants

Description

What is a Steel bar cutting machine?

Steel bar cutting machine are industrial equipment designed to cut steel bars (rebar) into precise lengths for construction and engineering projects. They are commonly used in building, bridge, and infrastructure projects.

Why Choose Our Steel Bar Cutting Machine?

- Factory direct sales, extremely competitive pricing

- High cutting precision and fast speed

- Heavy-duty frame for extended service life

- Low maintenance costs

- Compliant with CE/ISO standards

- Customizable voltage (110V–480V)

Steel Bar Cutting Machine Specifications

| Model | GQ40 | GQ45 | GQ50 | GQ60 |

| Round bar | Φ6-Φ40mm | Φ6-Φ45mm | Φ6-Φ50mm | Φ6-Φ60mm |

| Control mode | Clutch | Clutch | Clutch | Clutch |

| Cutting Freqency | 32 times/min | 32 times/min | 32 times/min | 56 times/min |

| (Times/min) | ||||

| Tensile strength of reinforcement | Ub≤450Mpa | |||

| Motor power (KW) | 2.2 | 3 | 4 | 5.5 |

| L*W*H (mm) | 1370 * 500 * 750 | 1370 * 500 * 750 | 1370 * 500 * 750 | 1370 * 500 * 750 |

| Weight (kg) | 400 | 485 | 640 | 650 |

Product Features

- Cutting Capacity: Handles steel bars up to 50mm in diameter, with variations for different steel types (e.g., II-grade deformed steel up to 42mm)

- Motor Power: Typically equipped with a 4KW motor, ensuring efficient operation

- Cutting Speed: Operates at a frequency of 32-56 cuts per minute, depending on the model

- Voltage: Supports 220V~440V power supply, making it adaptable to different worksite conditions

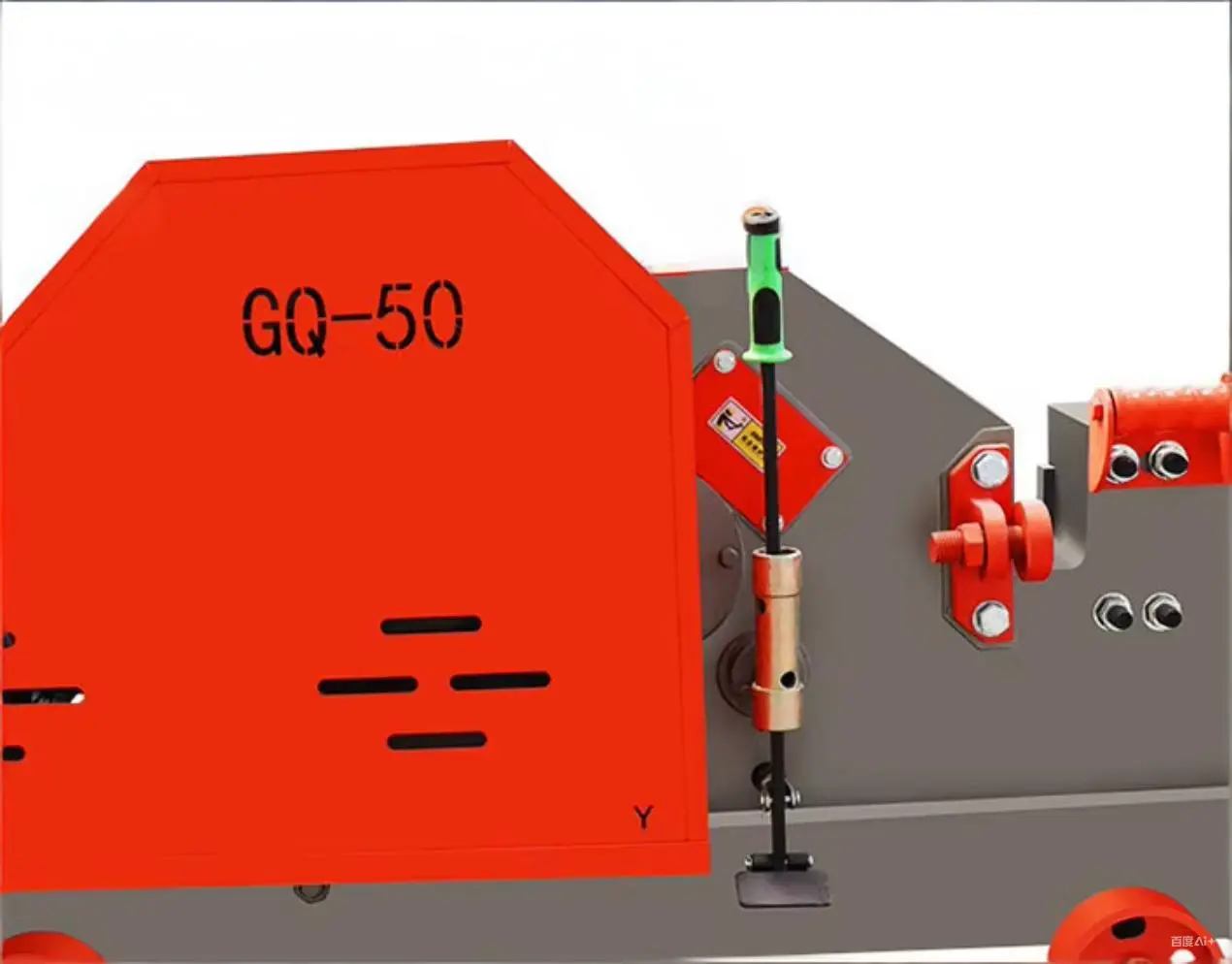

- Design: Compact structure with a solid fuselage, often featuring wheels for easy mobility. Some models include a yellow section to enhance operator safety in cluttered workshops

- Lubrication: Uses a full-closed gear splash lubrication system, reducing maintenance needs and allowing continuous operation for extended periods.

Product Detail

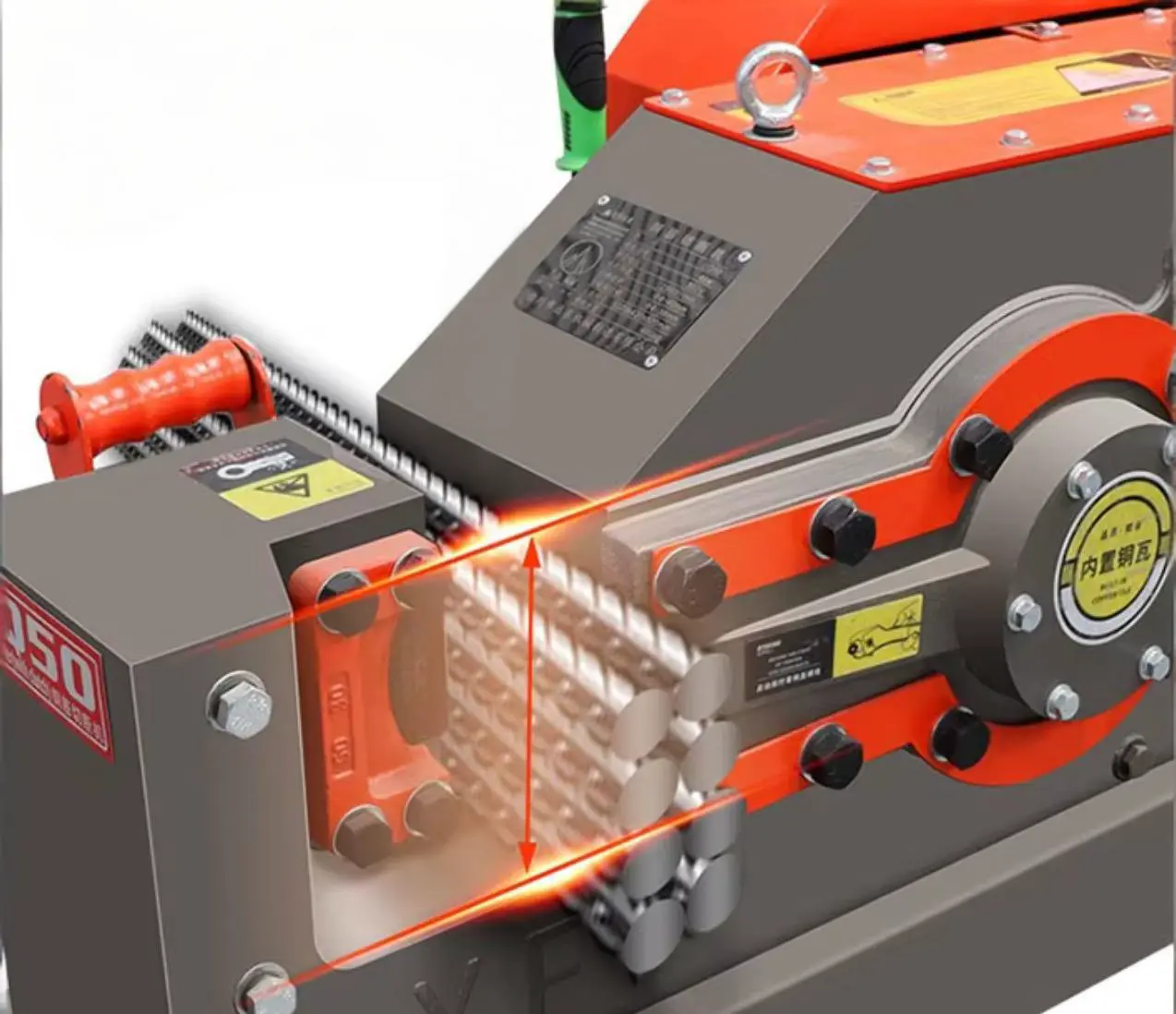

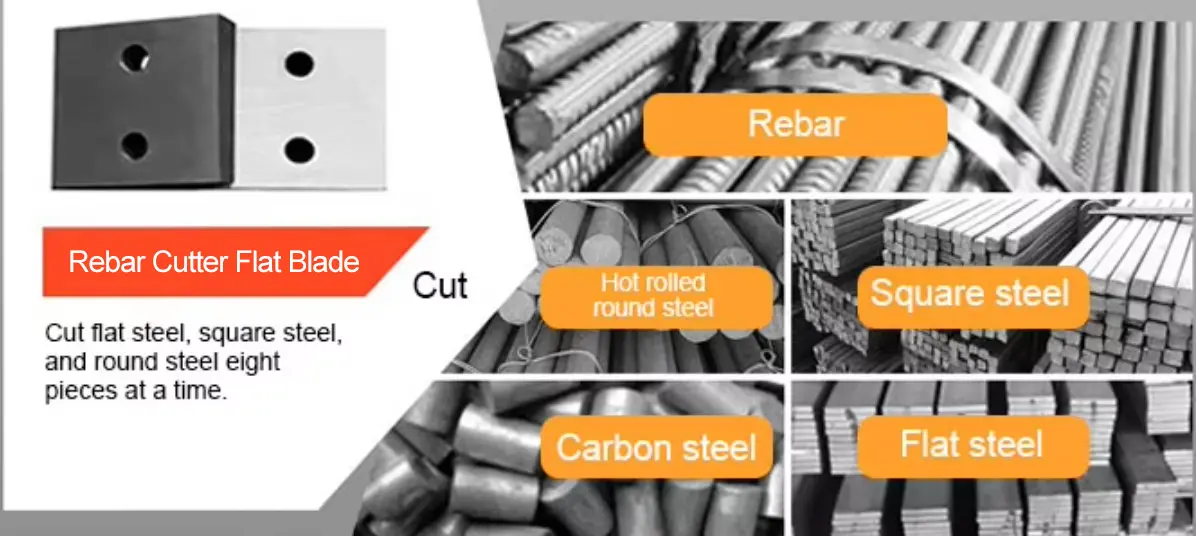

Deepening the material trough can cut 8 pieces at once

Deepening the material trough can cut 8 pieces at once

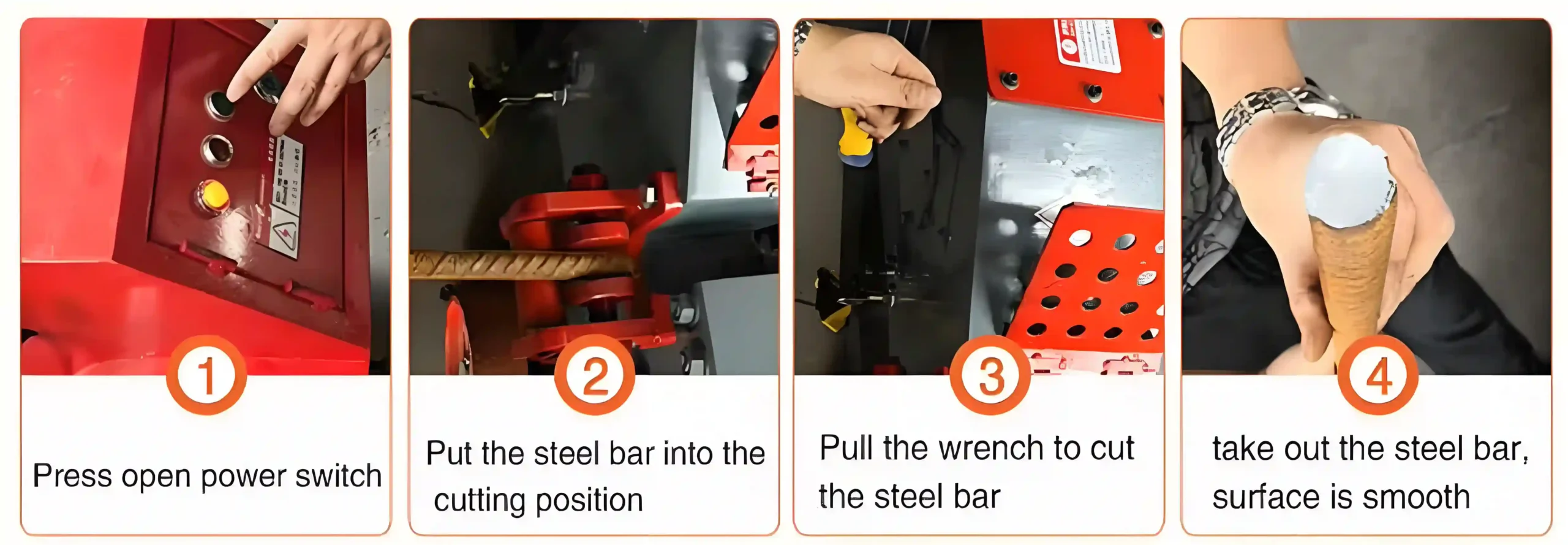

The fastest way to cut a rebar in 2 seconds, saving time and effort.

High-quality motors

High-quality export-grade high-power motors feature copper-core construction, offering robust overload resistance and preventing burnout even under intense operational demands.

Wear resistance

High strength bolt with higher wear resistance Design of unique feed pulleyHigh quality spare parts, such as thickening blade and side cover, The wear resistance of the product is high.

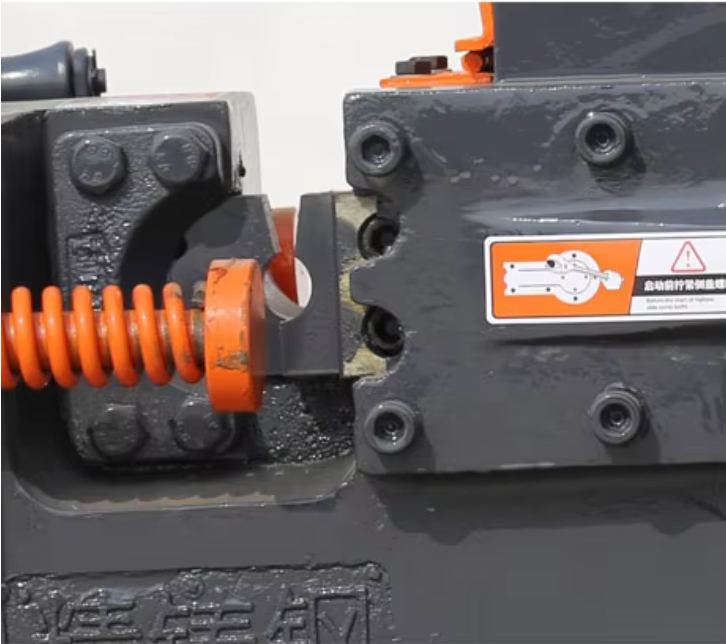

Dual control clutch lever manual foot operated

Manual and foot operation can be switched conveniently.

Steel Bar Cutting Machine Working Video

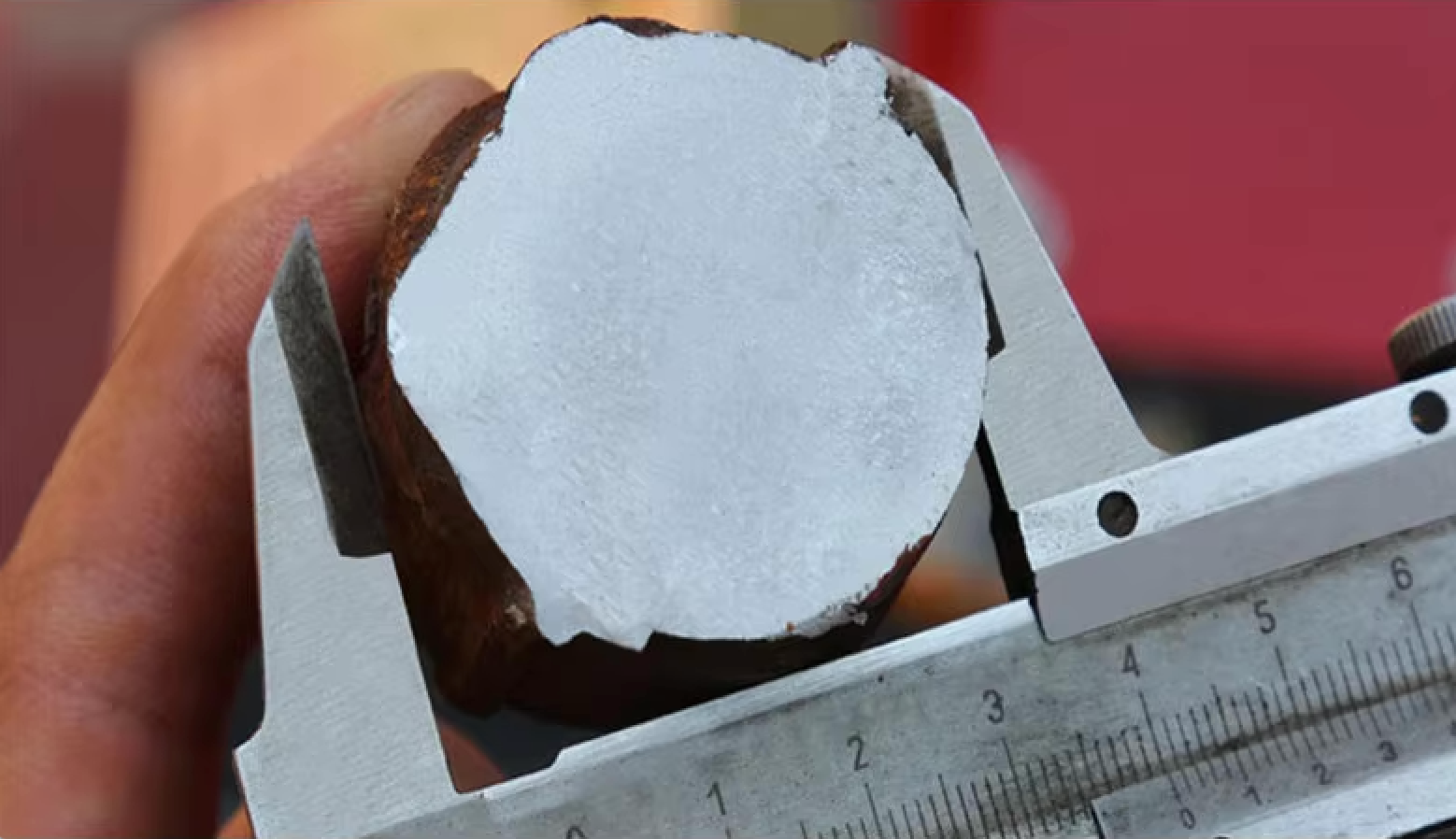

Cutting Effect

Precautions before operation

- Operators must wear protective clothing, hats, and safety goggles to prevent injury from metal fragments.

- Inspect the cutting blades for cracks or damage, ensure the blade holder bolts are tightened, and verify the guard is securely fastened.

- Manually rotate the pulley to check gear meshing clearance and adjust the blade gap.

- Verify power connections are correct, and confirm the leakage protector and electrical components have intact insulation.

- Ensure the equipment’s grounding system is reliable and effective.

operating procedure

Applications

- Construction Engineering: Used for processing reinforcing bars in reinforced concrete structures, featuring automatic feeding, positioning, and counting to enhance efficiency and ensure dimensional accuracy.

- Bridge Construction: Meets the high standards for reinforcing bar processing precision and cut surface quality required in bridge construction, while adapting to complex working environments.

- Rail Transit: Applied in subway and light rail projects to ensure rebar processing quality and schedule adherence while meeting environmental requirements.

- Shipbuilding: Provides high-precision cutting to meet rebar processing demands for hull structures and equipment installation.

- Precast Component Production: Automates rebar cutting for rapid production of precast beams, slabs, and other components, ensuring dimensional stability.

- Municipal Construction: Used for cutting rebar in municipal facilities like road guardrails and plaza sculptures, enhancing construction efficiency.

- Scrap Metal Recycling: Rapidly cuts bundles of scrap rebar for easy sorting and recycling, reducing resource waste.

Packaging & Delivery

we support three-way transportation by sea,landand air, just to better deliver the goods to you!

FAQ

1. What are the special safety requirements for cutting short steel bars?

- The distance between the hand and the cutting blade must be maintained at over 150mm.

- When the hand-held end is less than 400mm, a sleeve or clamp must be used to secure or firmly hold the short end of the steel bar.

- Directly feeding material by hand for cutting operations is strictly prohibited.

2. How to adjust cutting parameters?

- Adjust machine settings according to rebar specifications and project requirements.

- Before cutting, ensure cutting depth and blade clearance are correctly adjusted.

- When shearing low-alloy steel, replace with high-hardness blades; diameter must comply with nameplate specifications.

3. Can rebar exceeding the specified diameter be cut?

- Absolutely prohibited. Do not cut rebar whose diameter or strength exceeds the machine nameplate specifications, nor cut red-hot rebar. When cutting multiple bars simultaneously, the total cross-sectional area must remain within the specified range.

4. What precautions should be taken when cutting long steel bars?

- When processing longer steel bars, a designated person must assist and follow the operator’s instructions.

- During two-person operation, coordination is required; avoid arbitrary pushing, pulling, or dragging.

5. Can the machine start working immediately after startup?

- No. After startup, perform an idle run first. Only proceed with operation after confirming all transmission components and bearings are functioning normally. Do not cut materials until the machine reaches normal rotational speed.

6. How should cutting tools be maintained?

- Regularly inspect tool sharpness and wear resistance, replacing worn tools promptly.

- Check blades for cracks and ensure secure installation.

7. What are the differences in cutting rebar of various materials?

- Carbon steel: Use standard blades.

- Low-alloy steel: Must switch to high-hardness blades.

- High-strength steel: Verify it falls within the equipment’s rated capacity; never overload the machine.

8. How can cutting quality issues be prevented?

- Ensure the rebar remains perpendicular to the blade edge to prevent end wobbling.

- Securely clamp the rebar before cutting using a vise or fixture.

- Maintain consistent blade speed and depth while applying even pressure during advancement.