Fully Auto metal cutting band saw

Description

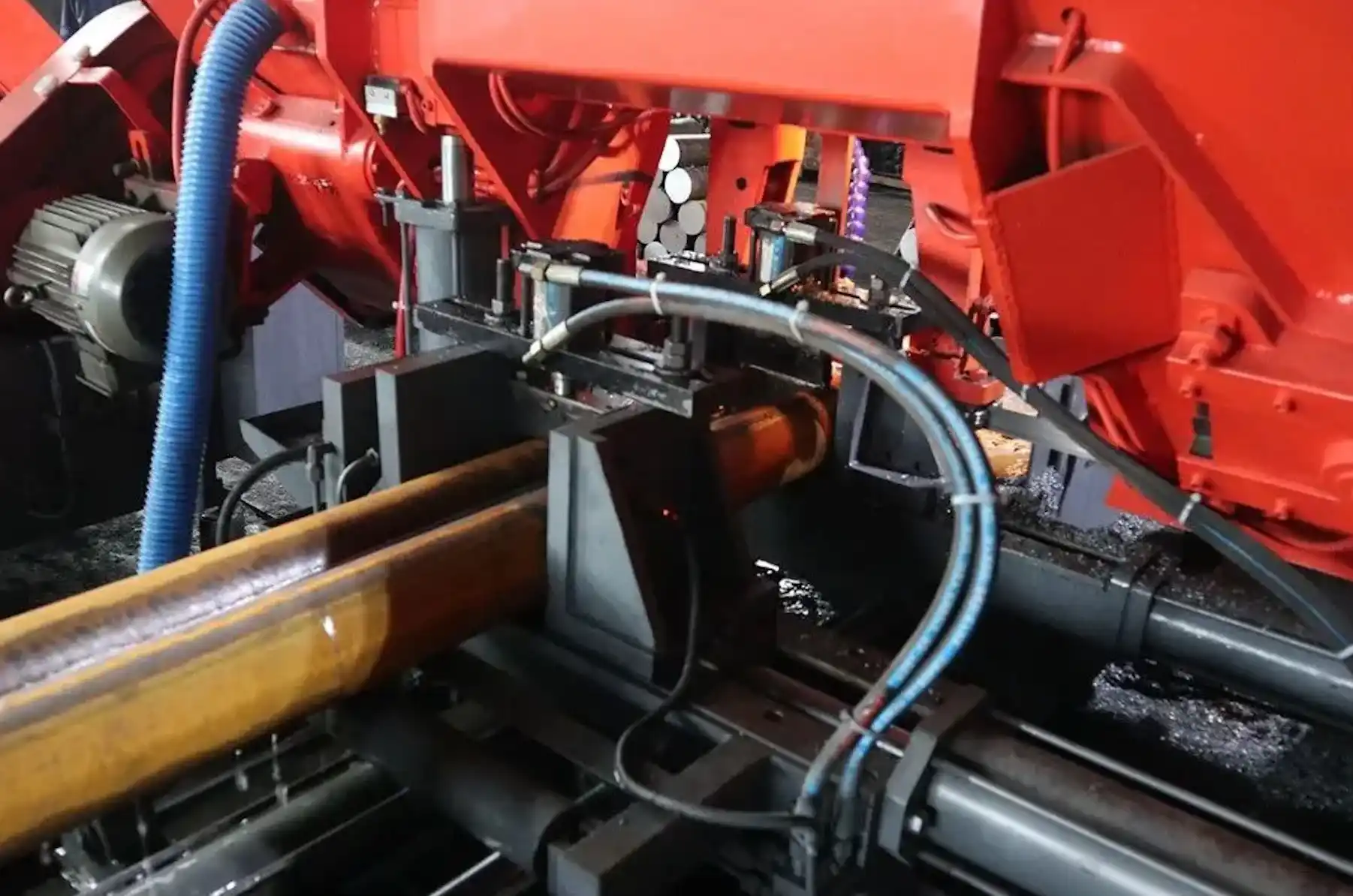

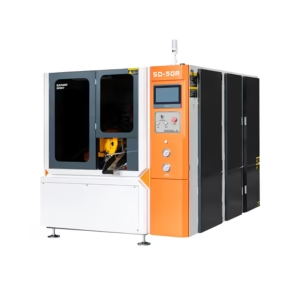

The fully auto metal cutting band saw is a highly efficient, precise, and automated machine designed for cutting metal materials.

Featuring automatic feeding, clamping, cutting, and shutdown functions, it significantly reduces operator workload and minimizes human error’s impact on cutting quality and efficiency. Even non-professionals can operate it proficiently after minimal training.

Capable of sawing various ferrous and non-ferrous metals, including carbon structural steel, alloy structural steel, stainless steel, bearing steel, and heat-resistant steel. It can also cut certain specialty metals and non-metallic materials, meeting the diverse needs of different industries and users.

During the production of rebar sleeves, the rebar making machine metal band saw is primarily used to rapidly cut raw materials to the required sleeve length.

Parameter of metal cutting band saw

| Parameter Name | Specific Value |

| Sawing Range (mm) | Round Bar: ∅350; Square Bar: □350×350 |

| Band Saw Size (mm) | 4250×34×1.1 |

| Band Saw Wheel Diameter | ∅500 mm |

| Band Saw Speed (m/min) | Five Speeds: 22, 32, 43, 55, 65 |

| Band Saw Feed Speed | Hydraulic Control (None) |

| Motor: Band Saw Main Drive | 3.0KW, 6-pole |

| Motor: Hydraulic Drive | 0.75KW, 4-pole |

| Main Motor Power (kw) | 3 |

| Hydraulic Pump Power (kw) | 1.5 |

| Cooling Pump Power (kw) | 0.04 |

| Hydraulic Oil Tank Capacity | 18 Liters |

| Cutting Fluid Tank Capacity | 40 Liters |

| Cutting Fluid Pump | Water Pump DB-12A |

| Power | 40W 380V |

| Machine Overall Dimension (L×W×H, mm) | 2200×2300×1650 |

| Machine Weight (kg) | 2800 |

Product Features

- Utilizes a CPU microcomputer automatic control system to set the automatic program for the entire sawing process, with manual operation also available.

- The human-machine interface displays equipment operating status, parameter settings, and operational instructions, ensuring simple and efficient operation.

- Features built-in operating instructions and backend statistics for sawing data, offering simplicity, clarity, and convenience.

- Multiple settings for cutting length, group count, and quantity with real-time display. Feed length controlled by magnetic scale with dimensional accuracy within 0.2mm.

- Hydraulic workpiece clamping and feed options available. Hydraulic stepless speed adjustment for cutting.

- Flexible saw blade tensioning extends blade lifespan. Rational structure with heavy bed and stable saw frame ensures reliable performance and high precision.

- Active steel brush debris removal system combined with water flushing ensures thorough cleaning, prolonging saw blade life.

- Scientifically designed saw blade guidance system utilizes rolling bearings and carbide blocks for precise cutting accuracy and reduced blade wear.

- Bundle sawing device—top clamping (optional accessory).