Rebar anchor plate with flange hex nut

- Optimize space: significantly reduce the required anchorage length and effectively solve the problem of steel reinforcement congestion.

- Quality assurance: Ensure that the concrete is poured densely and improve the overall structural integrity.

- Improve efficiency: Easy installation, accelerate construction progress, save labor and material costs.

- Excellent performance: The anchoring performance is stable and reliable, fully meeting the regulatory requirements.

Description

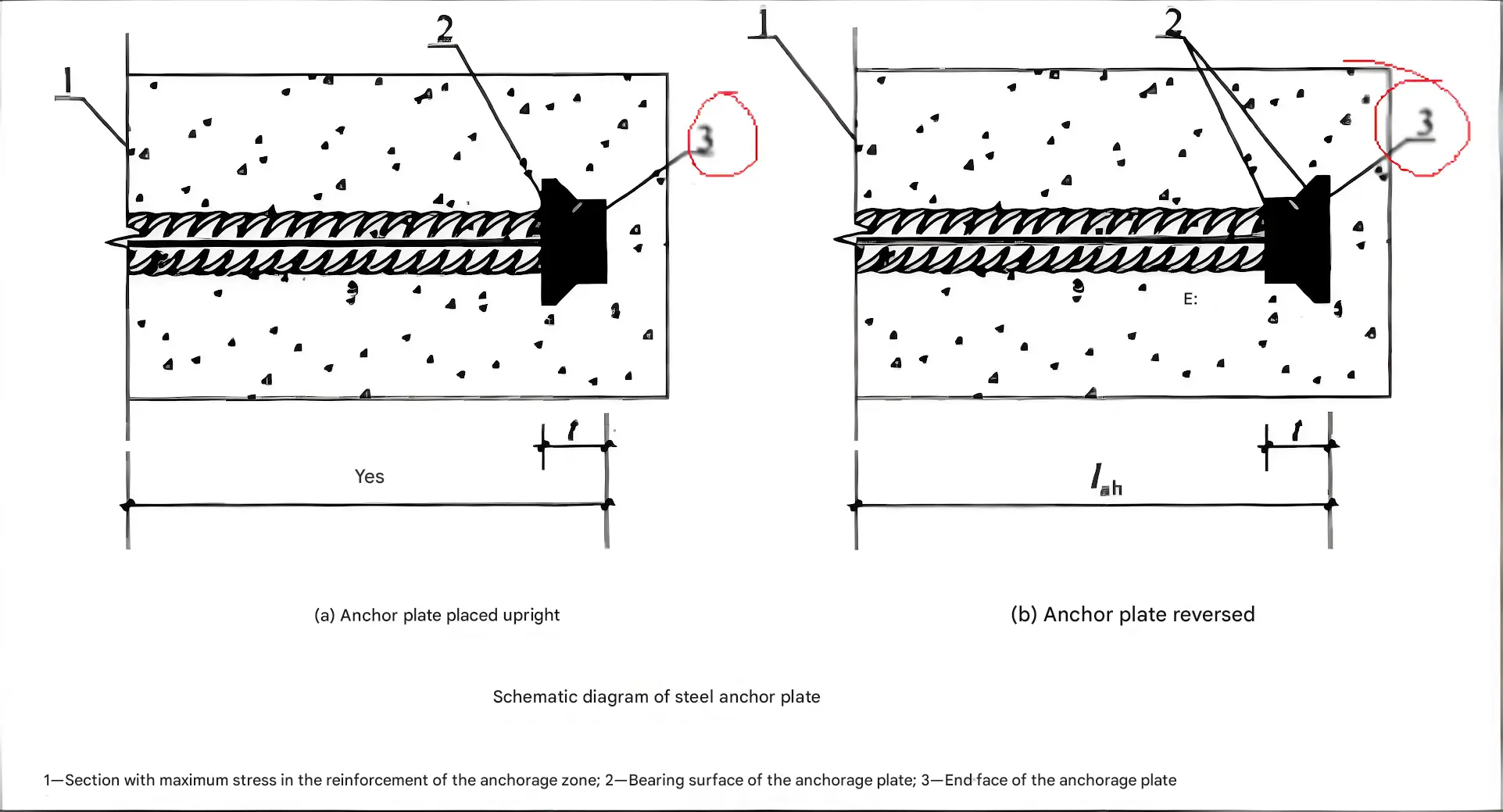

The Rebar anchor plate with flange hex nut, commonly referred to as an anchor plate, comprises an external hex nut and washer integrated into a single unit. This anchor plate represents an innovative mechanical anchoring method for concrete structures. By connecting the washer (load-bearing plate) and nut (connection end) into a unified anchor plate, it forms a mechanical anchorage system through direct threaded connection with the top of the reinforcement bar.

We provide custom-engineered rebar anchor plate solutions tailored to your project specifications. Contact our experts to discuss your requirements.

Classification of Rebar anchor plate

| Classification Method | Category (plain English) |

| By Material | • Ductile-iron anchor plate • Structural-steel anchor plate • Forged-steel anchor plate • Cast-steel anchor plate |

| By Shape | • Round • Square • Rectangular |

| By Thickness | • Uniform thickness • Variable thickness |

| By Connection Type | • Threaded (coupler) plate • Welded plate |

| By Load-transfer Capacity | • Partial bearing anchor plate • Full-coverage anchor plate |

Working Principle of the rebar anchor plate

The anchoring force of reinforcing bars = the bond strength between the bars and concrete + the local bearing capacity of the anchor plates.

Product Advantage

- Reliable performance: Exceptional anchoring capability ensures structural safety.

- Efficient construction: Simple operation significantly accelerates construction speed.

- Material savings and reduced consumption: Minimises reinforcement usage, aligning with green construction principles.

- Quality assurance: Effectively overcomes congestion issues associated with traditional bent rebar anchoring, ensuring concrete pouring quality and thereby comprehensively enhancing overall project quality.

What problem does the rebar anchor plate solve

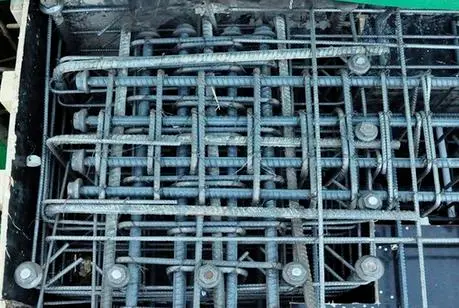

In modern public building design, in order to meet high seismic fortification requirements, the reinforcement configuration of key parts such as beam column nodes and raft foundations is becoming increasingly dense.

This has led to two core challenges:

- Insufficient anchorage length: Constrained by available space, the anchorage length of reinforcing bars struggles to meet code requirements.

- Construction quality risks: Overcrowding of reinforcing bars impedes concrete placement and compaction, increasing susceptibility to voids, poor compaction, and other quality defects.

Solution

- Employ CABR reinforcement anchor plate technology, substituting high-quality anchor plates for portions of the traditional reinforcement anchorage length.

- This approach effectively optimises reinforcement intersection nodes, fundamentally resolving the issue of ‘reinforcement congestion’.

Application

- Public buildings with stringent seismic design requirements

- Reinforcement-dense areas such as beam-column joints and raft foundations

- Situations where conventional anchorage lengths prove inadequate or concrete pouring presents difficulties

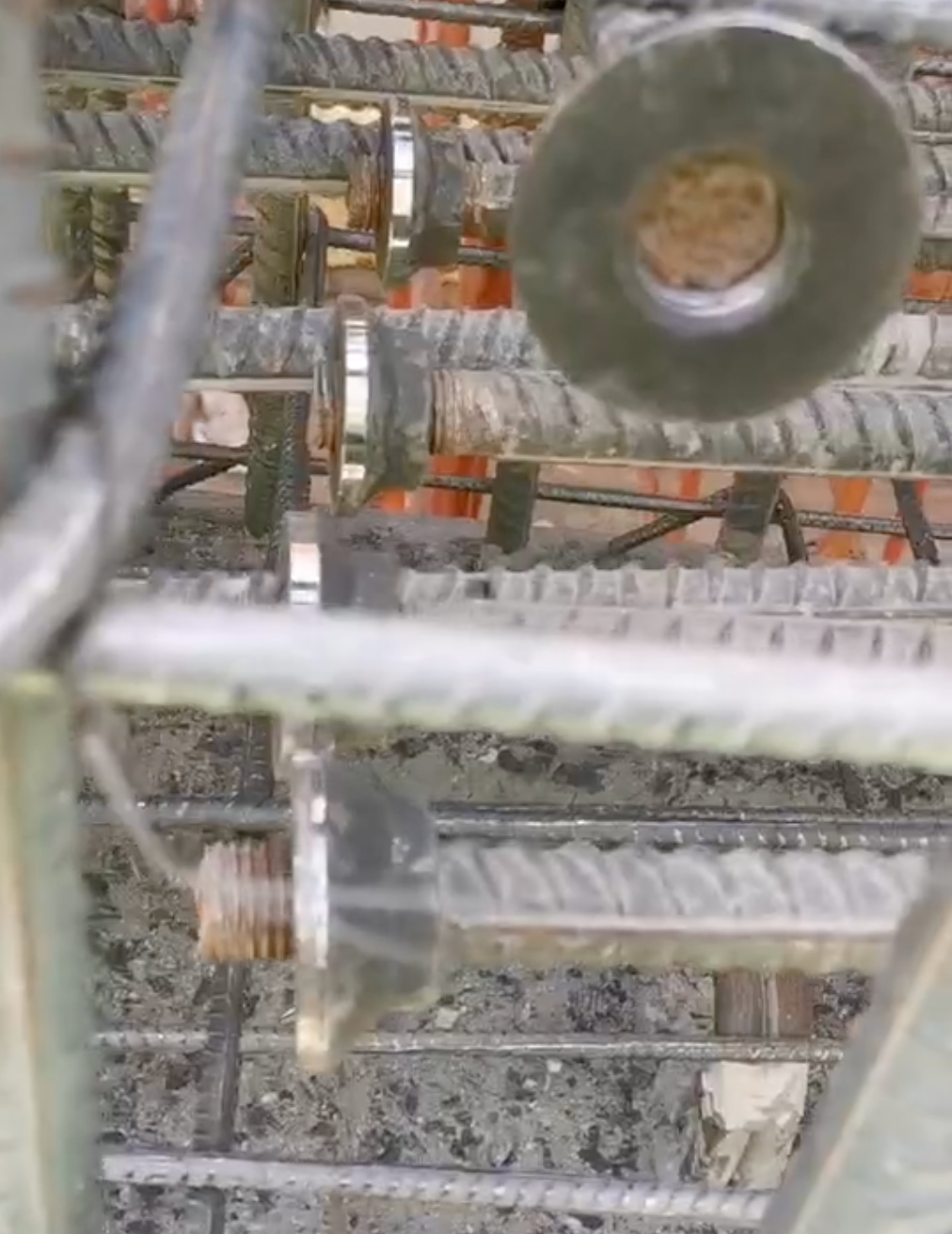

Common Issues in Project

1. Loose or missing anchor plates;

2. Reinforcing bar threads not protruding beyond the anchor plate;

3. Loose anchor plates, or corrosion of anchor plates and reinforcing bars;

4. Contamination of anchor plates and reinforcing bars.