rebar Upsetting Machine

Description

Rebar upsetting machines are primarily employed for processing the heads of ribbed steel bars in construction projects, serving as essential equipment for achieving rebar connections. These devices are chiefly categorised into single-cylinder cold forging machines and double-cylinder rebar head forming machines.

Rebar heading machines must be used in conjunction with rebar threading machines. After rebar heads are first swaged thicker via the heading machine, they require subsequent processing through a rebar thread rolling machine. This significantly enhances the strength of structural steel connections. This rebar heading machine offers straightforward operation, rapid processing speeds, and high-quality results, making it suitable for demanding construction projects such as highway bridges, high-speed railways, underground railways, and tunnels.

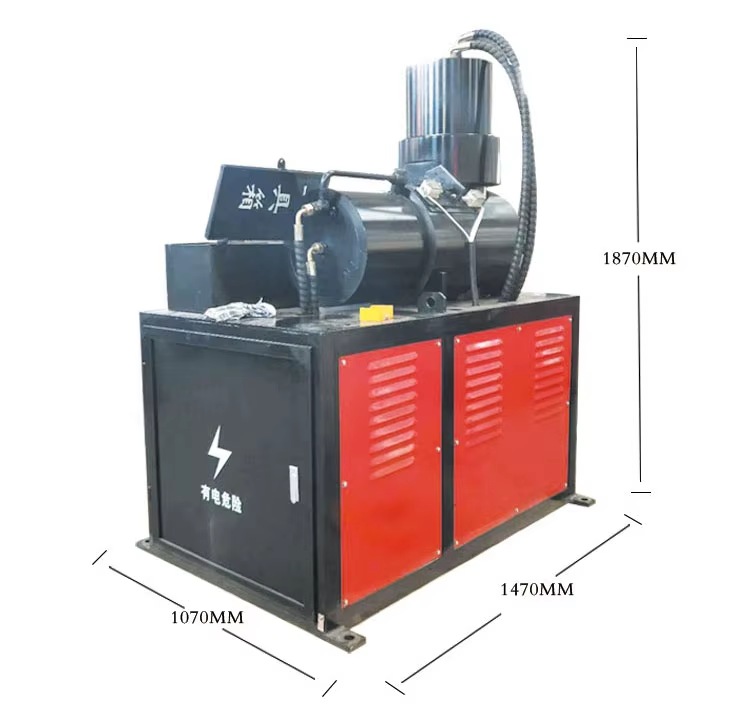

Technical Parameter of Rebar upsetting machines

| Model | HDCJ-32S | HDCJ-40S | HDCJ-50S |

| Upsetting range: | D16-32mm | D16-40mm | D16-50mm |

| Motor power: | 7.5kw | 7.5kw | 11kw |

| Upsetting length: | 3-5cm | 3-5cm | 3-6cm |

| Working capacity: | 15-20 seconds/pcs | 15-20 seconds/pcs | 15-20 seconds/pcs |

| Packing size(mm) | 1250 X 850 X 1650 | 1250 X 850 X 1650 | 1350 X 950 X 1750 |

| Weight | 980KG | 1200KG | 1500KG |

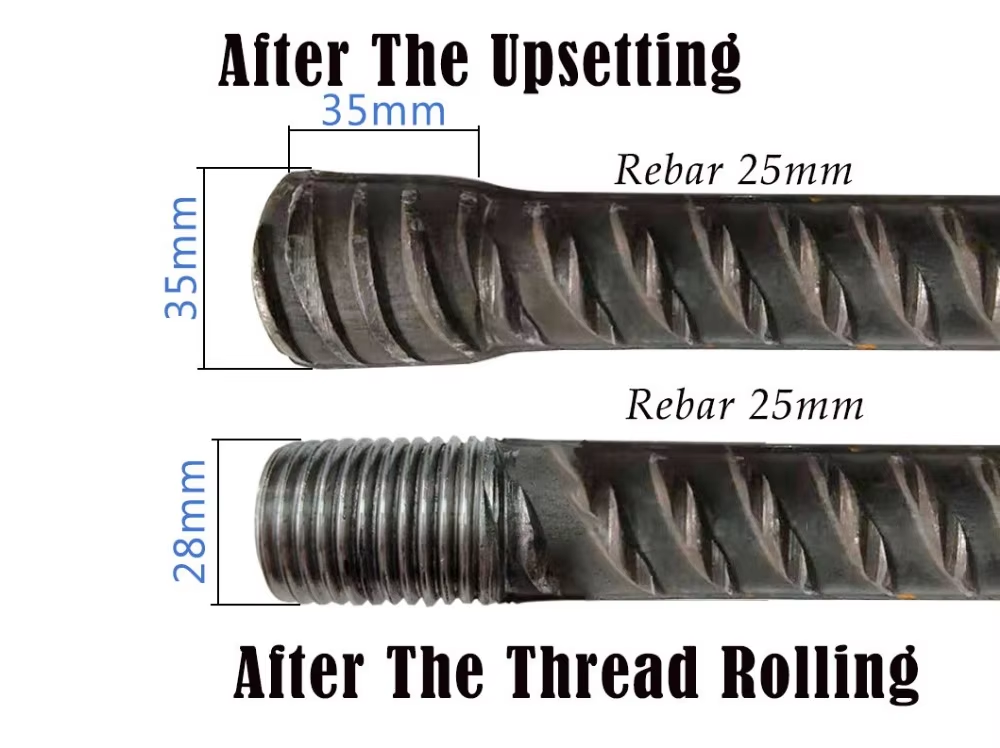

Post-processing effect of rebar upsetting machine

Working Principle of the Upsetting Machine

The double-cylinder upsetting machine adopts the mechanical structure completed by the extrusion and clamping synchronously, and uses the principle of cold heading to pre-form the plastic section of the end of the steel bar to be coarsely deformed, so that the diameter of the The large bar of the processing section is increased and the diameter is increased, and the effective diameter is increased. The large 4~mm, the cross-sectional area after the upsetting is much larger than the cross-sectional area of the original steel base material , greatly improving the tensile strength of the joint.The thickened section of the reinforcing bar is then threaded, before being connected to the upset thread rebar coupler, thereby enhancing the overall tensile strength of the reinforcement.

7 Features of Rebar Upsetting Machine

1、Simple operation: The equipment is straightforward to operate, requiring only one person to complete the process. Once the reinforcing bar is positioned correctly, pressing the foot switch initiates automatic operation, reducing labour intensity and making it suitable for continuous operation.

2、Strength Enhancement: The cold heading process increases the diameter of the rebar ends. The actual cross-sectional area after threading exceeds that of the original rebar, ensuring the joint strength surpasses that of the parent material. This effectively improves the joint’s tensile and compressive properties, making it suitable for critical projects with high strength requirements, such as bridges and underground railways.

3、Stable Performance: Joint strength remains unaffected by tightening torque. Even if threads loosen or 2-3 threads are under-tightened, joint strength suffers no significant reduction. This minimises the impact of manual operation and torque measurement tools on joint performance, guaranteeing consistent connection quality.

4、Rapid Connection: Featuring a coarse-pitch thread design requiring fewer turns, no torque wrench is needed. Connection is simple and swift, significantly boosting construction efficiency.

5、High Production Efficiency: Rapid on-site upsetting processing achieves individual thread head fabrication in just 30-50 seconds. Each shift can process 400-600 thread heads, meeting large-scale construction demands.

6、High Adaptability: Processes multiple rebar specifications, typically suitable for HRB335 and HRB400 grade threaded bars ranging from 12-40mm in diameter, fulfilling diverse rebar connection requirements across projects.

7、Environmentally Friendly and Safe: The process generates no pollution, operates unaffected by environmental or climatic conditions, and features a compact, stable, and highly secure equipment design.

Preparation for upsetting machine processing

1、Pre-processing operations

1. Connect the power cable. The power supply is three-phase four-wire. Before energising, ensure the machine body is properly earthed.

2. Fill the tank with hydraulic oil to the required level, approximately 75 litres. The oil level can be observed via the sight glass.

3. Check that all components operate freely.

2、No-Load Test Run

1. Switch on the power supply and press the start button. Observe whether the motor rotation direction is correct. If incorrect, swap any two phases of the three-phase power supply.

2. Operate the control buttons and observe whether each button functions consistently (Note: Finally observe automatic operation).

3、Machine adjustment

1. Prior to processing, select the appropriate mould based on the diameter of the reinforcing bar to be processed.

2. Mould replacement: First remove the stroke limit bracket, then press the cylinder retract button to return it to its starting position. then press the cylinder lift button to raise the lower cylinder to its starting position. Remove the screws at both ends of the upper mould to extract it from the centre. Subsequently, remove the lower mould and the end clamping plates to extract the lower mould from the centre. Install the mould matching the rebar diameter by reversing the above procedure. Check whether the upper mould operates smoothly; if not, disassemble it and grind the sliding surfaces.