Steel Bar Thread Rolling Machine

Description

The Z28-200 Steel Bar Thread Rolling Machine is primarily employed for rolling various precision external threads and high-strength standard components, including plain threads, trapezoidal threads, and metric threads. It features a rational design, substantial processing capacity, and high efficiency.

Steel Bar Thread Rolling Machine Advantages

1、High-efficiency machining capability

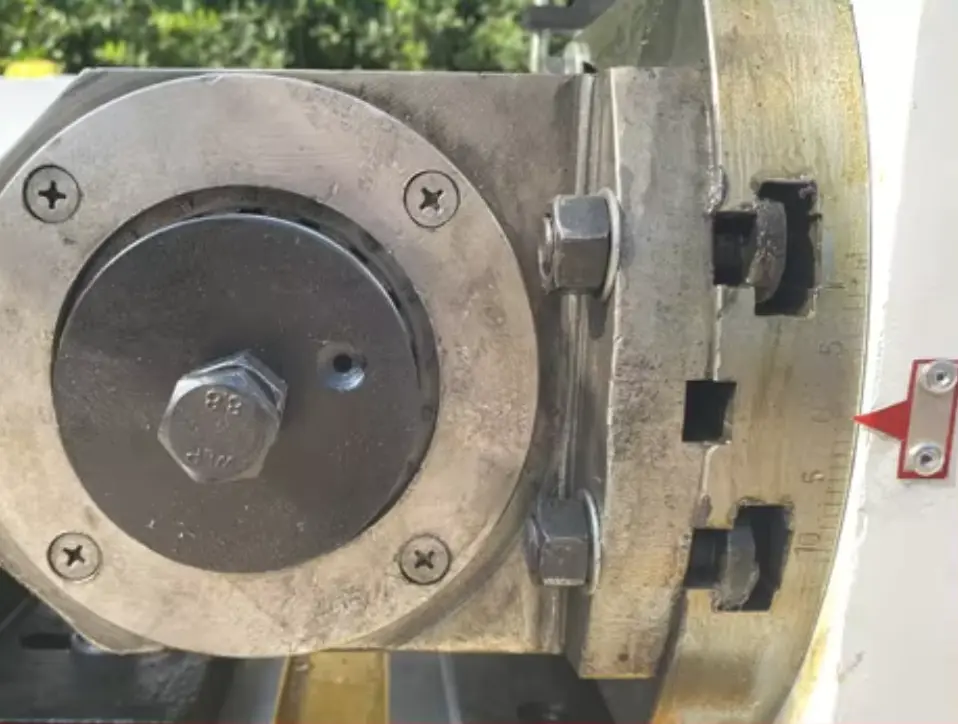

The Z28-200 Steel Bar Thread Rolling Machine delivers a maximum rolling force of 200kN, enabling rapid thread rolling of various specifications. It is suitable for components such as building wall-penetrating bolts, trapezoidal threads, and metric threads, with no restrictions on thread length (requires additional protective devices). The spindle speed is adjustable (16, 26, 38, 55, 90 rpm), complemented by radial and axial feed functions. This adaptability to different materials and process requirements significantly enhances production efficiency.

2、High Precision and Stability

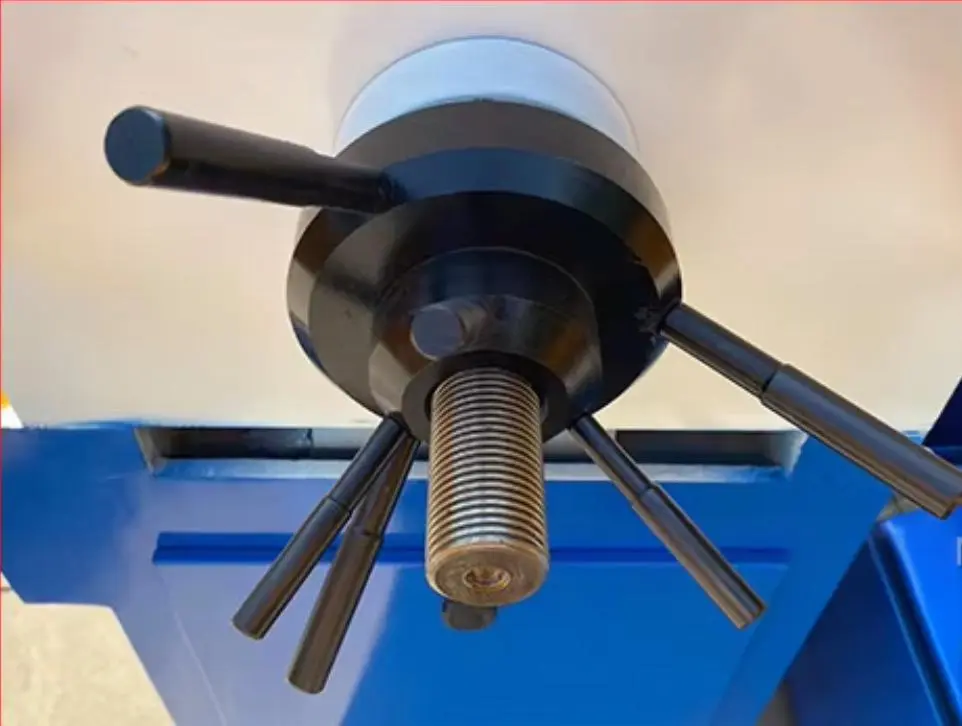

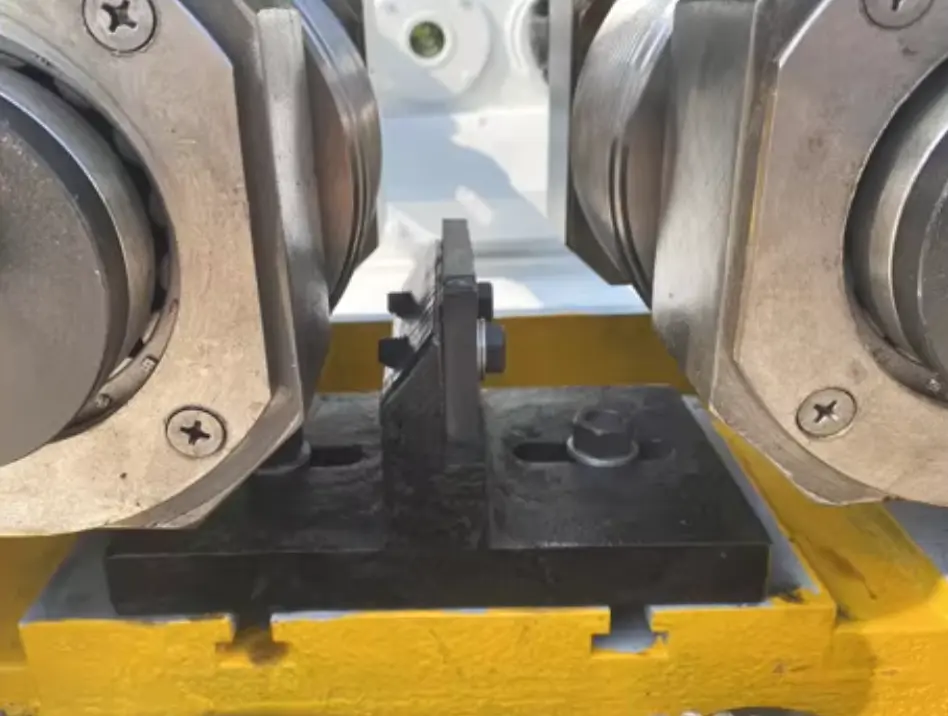

With a maximum thread rolling wheel diameter of 210mm, bore diameter of Φ75mm, spindle tilt angle of ±12°, and spindle centre distance of 150-270mm, these design parameters ensure machining accuracy and stability. The equipment employs a precision-cast forged headstock, featuring a robust structure and convenient adjustment, minimising the occurrence of thread misalignment. It is suitable for applications demanding high thread precision.

3、Multi-functional Cold Extrusion Forming

As a multi-functional cold extrusion forming machine tool, the Z28-200 Steel Bar Thread Rolling Machine can perform cold-state thread rolling, straight-line rolling, helical rolling, straightening, neck-down forming, burnishing, and various forming roll processes. Its multi-purpose capability reduces equipment procurement costs and footprint.

4、Operational Ease and Safety

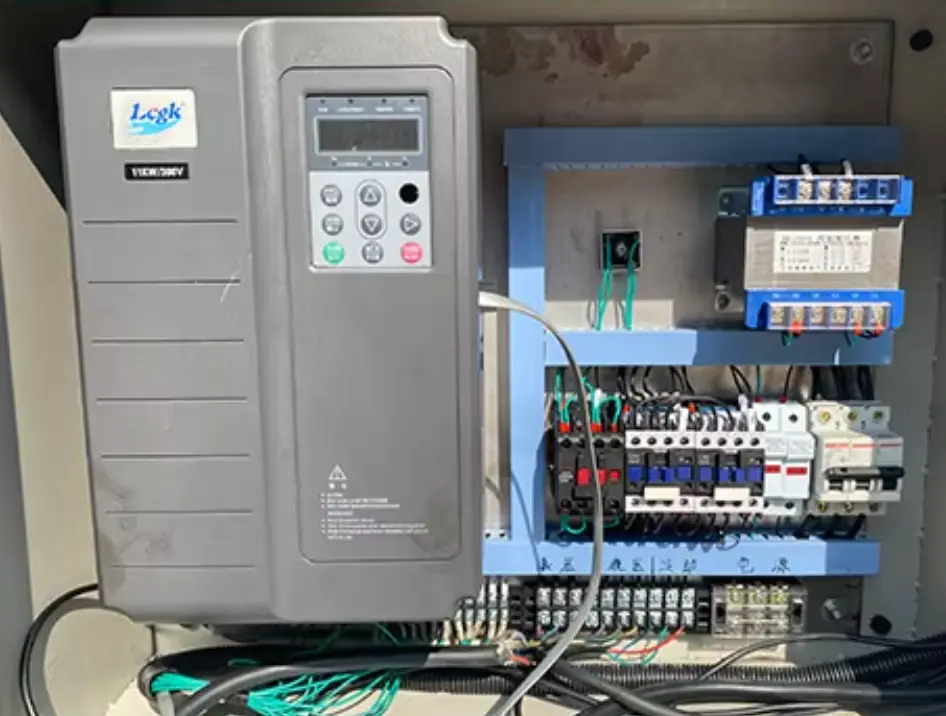

The equipment is fitted with a secure and dependable Electro-hydraulic drive and control system, supporting manual, semi-automatic, and fully automatic operating modes. Its operation is straightforward and easy to learn. Additionally, it incorporates hydraulic pressure indicators, rolling pressure indicators, and cooling status indicators, facilitating real-time monitoring of the equipment’s operational status to ensure safe operation.

5、Energy Conservation and Environmental Protection

The cold thread rolling process constitutes a non-cutting machining technique. Compared to conventional cutting methods, it effectively reduces material wastage and energy consumption. As an efficient, energy-saving, and low-consumption process, it aligns with the green production requirements of modern manufacturing.

Steel Bar Thread Rolling Machine Technical specifications

| Thread rolling range maximum diameter | 56mm |

| Minimum diameter | 5mm |

| Rolling wheel range outer diameter | 120-170mm |

| Rolling wheel aperture | 54mm |

| maximum width | 30-100mm |

| Maximum rolling pressure | 160 |

| Main axis | ±5° |

| Hydraulic auto feeding time regulation range | 0.1-99.9 |

| Cease time regulation range | 0.1-99.9s |

| Intermittent time | 0.1-99.9s |

| Spindle motor | 11KW-4 |

| Hydraulic motor | 4KW |

| Outer size (L*W*H) | 1550*1550*1450(mm) |

| Total Weight | 2000kg±50kg |

| Delivery time | 7days |

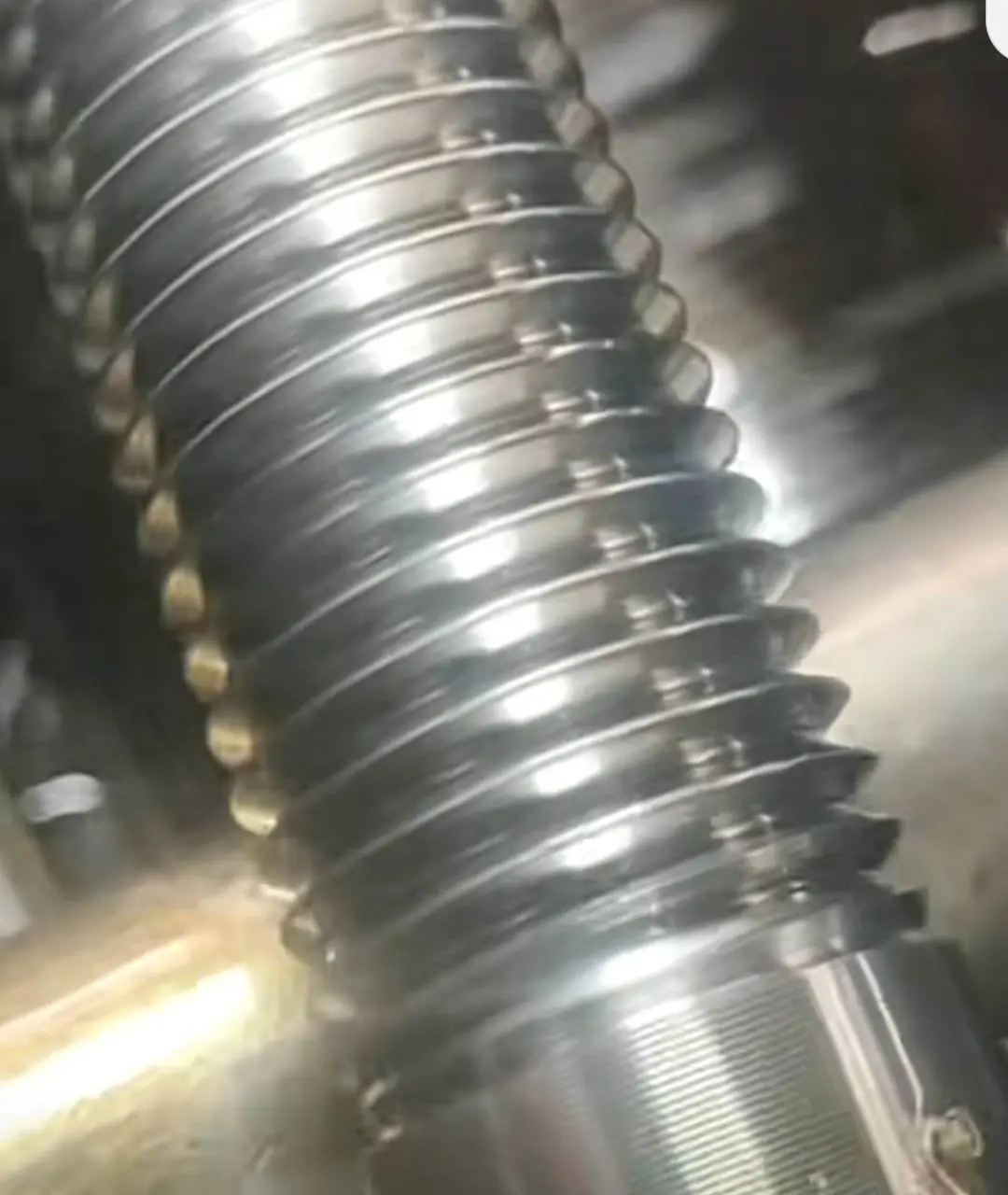

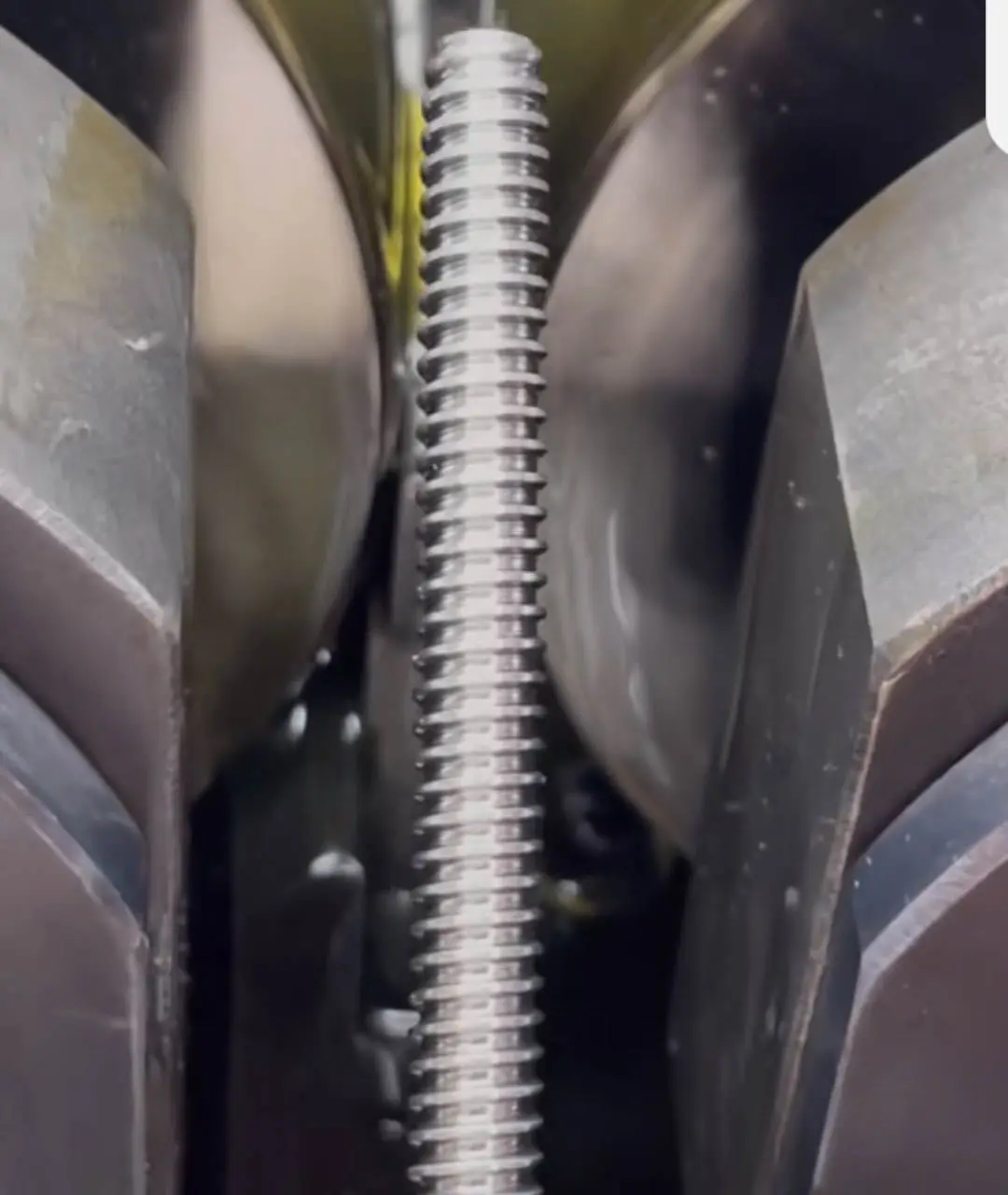

Steel Bar Thread Rolling Machine Detail

Processing effect

Operational Precautions

1. Operators must first read the operating manual to gain a thorough understanding of the thread rolling machine’s structure and functions, which is an essential prerequisite for operating any machinery;

2. Prior to running the steel bar thread rolling machine, inspect all components for any signs of looseness, breakage, or damage, and verify that the cutting fluid meets specifications. If no issues are found, proceed to add lubricant;

3. After adding lubricant, start the machine and allow it to rotate slowly. Observe whether the shaft wheels on both sides of the thread rolling machine operate normally and listen for any unusual noises. Additionally, verify that all system indicators display correctly;

4. Only proceed with normal operation if all the above points are satisfactory. During operation of the automatic thread rolling machine, hands must not be inserted into the shaft wheels. Even when adjusting the shaft wheels, the machine must be switched off and operation performed only when the shaft wheels have ceased rotating;

5. During initial operation, produce several test items and verify their compliance using a go/no-go gauge before proceeding with mass production.

6. Upon completion of part processing, inspect all machine components. Maintain the thread rolling machine’s cleanliness, eliminating any unusual oil stains from its exterior. Check the oil tank for leaks. Once all issues are resolved, switch off the power supply and conclude operations.